Intake system structure of power unit

A technology of power unit and system structure, applied in the direction of charging system, engine components, engine control, etc., can solve the problems of rotational position deviation of the fastening part, complex connection operation, complex structure, etc., to reduce the protrusion in the height direction, The effect of improving workability and suppressing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

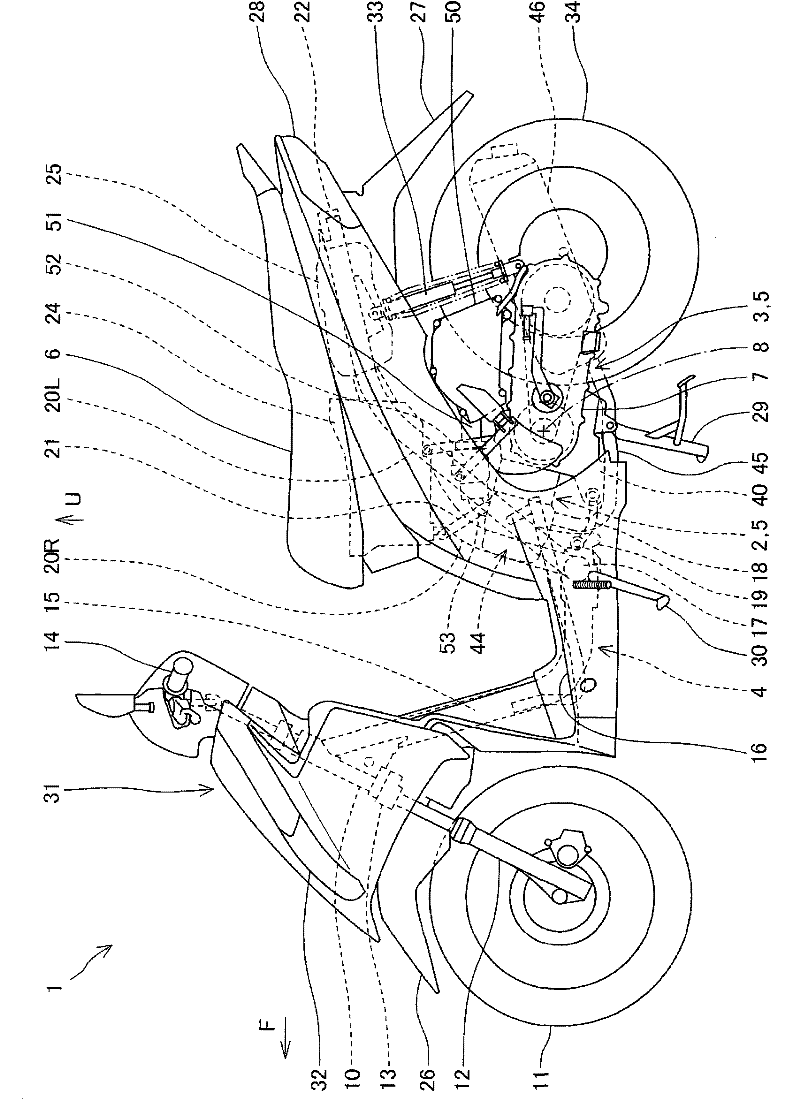

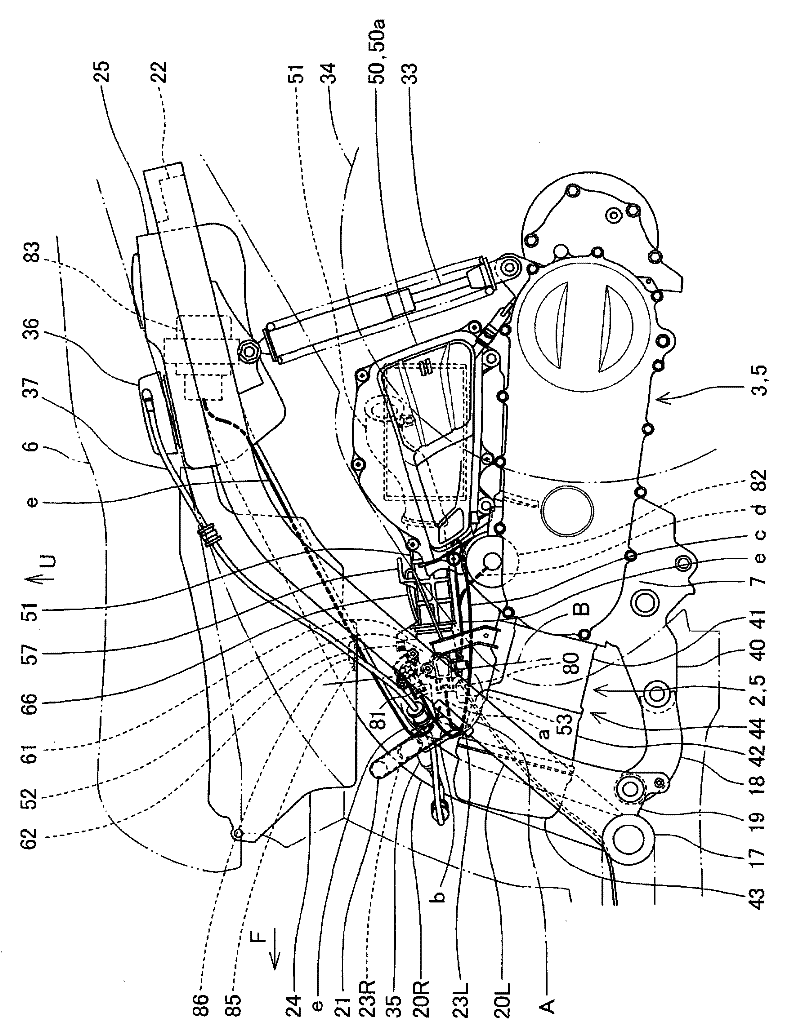

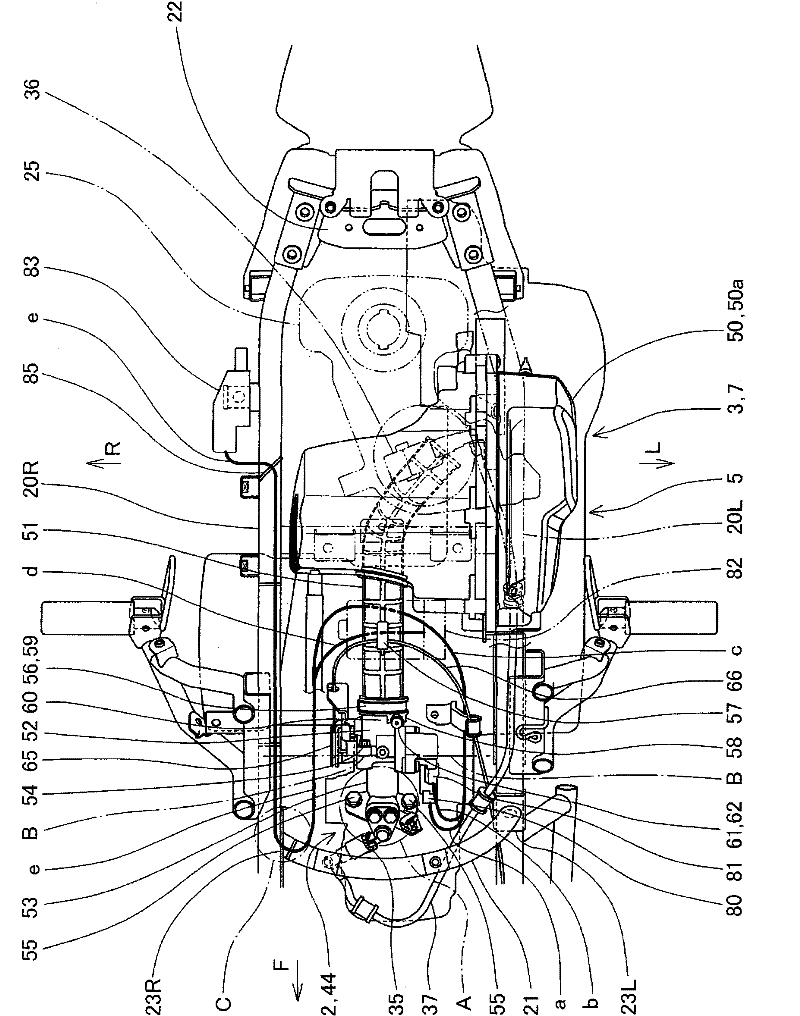

[0089] Below, refer to Figure 1 to Figure 9 , the configuration of the air intake system of the power unit according to the embodiment of the present invention will be described.

[0090] It should be noted that directions such as front, rear, left, right, up and down in the description of this specification and the claims refer to the directions of a vehicle in which the power unit according to this embodiment is mounted on a vehicle, particularly a small vehicle such as a motorcycle. direction. In the figure, arrow F indicates the front of the vehicle, L indicates the left side of the vehicle, R indicates the right side of the vehicle, and U indicates the upper side of the vehicle.

[0091] In addition, in the drawings, hollow arrows schematically indicate the flow of intake air to the internal combustion engine, small arrows m schematically indicate the flow of idle air, and small arrows n schematically indicate the flow of bypass air at startup.

[0092] figure 1 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com