Homogeneous compound catalyst/enzyme structure, fabricating method thereof and application thereof

A compound and uniform mixing technology, applied in electrolytic coating, electrophoretic plating, coating, etc., can solve the problems of decreased sensing ability, hydrogen peroxide diffusion hindrance, and the inability to reduce the production cost of miniature biosensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

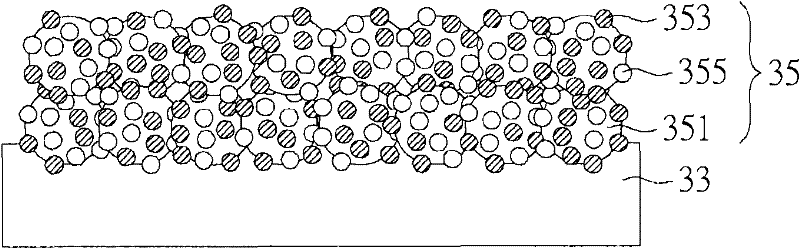

[0039] The invention proposes a composite catalytic enzyme membrane structure with a uniform structure, its preparation method and application. image 3 It is a schematic diagram illustrating the structure of a composite catalytic enzyme film according to an embodiment of the present invention. Wherein, a composite catalyst enzyme film 35 is formed on the surface of a substrate (for example, a working electrode) 33, and the composite catalyst enzyme film 35 includes a plurality of catalyst particles 353 and enzyme molecules 355 uniformly mixed and distributed, and the catalyst Particles 353 and enzyme molecules 355 are formed on the catalyst support 351 . Wherein, the enzyme molecules 355 are used to catalyze a biomolecular reaction, and the catalyst particles 353 are used to catalyze an electrochemical substance reaction. For example, in an application example, the enzyme molecule that catalyzes the reaction of biomolecules reacts with biomolecules to form hydrogen peroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com