Maskless photoetching alignment system

A maskless lithography and alignment system technology, applied in microlithography exposure equipment, optics, photolithography process exposure devices, etc., can solve the problems of complex structure and difficult implementation of the alignment system, and improve the alignment accuracy. , low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

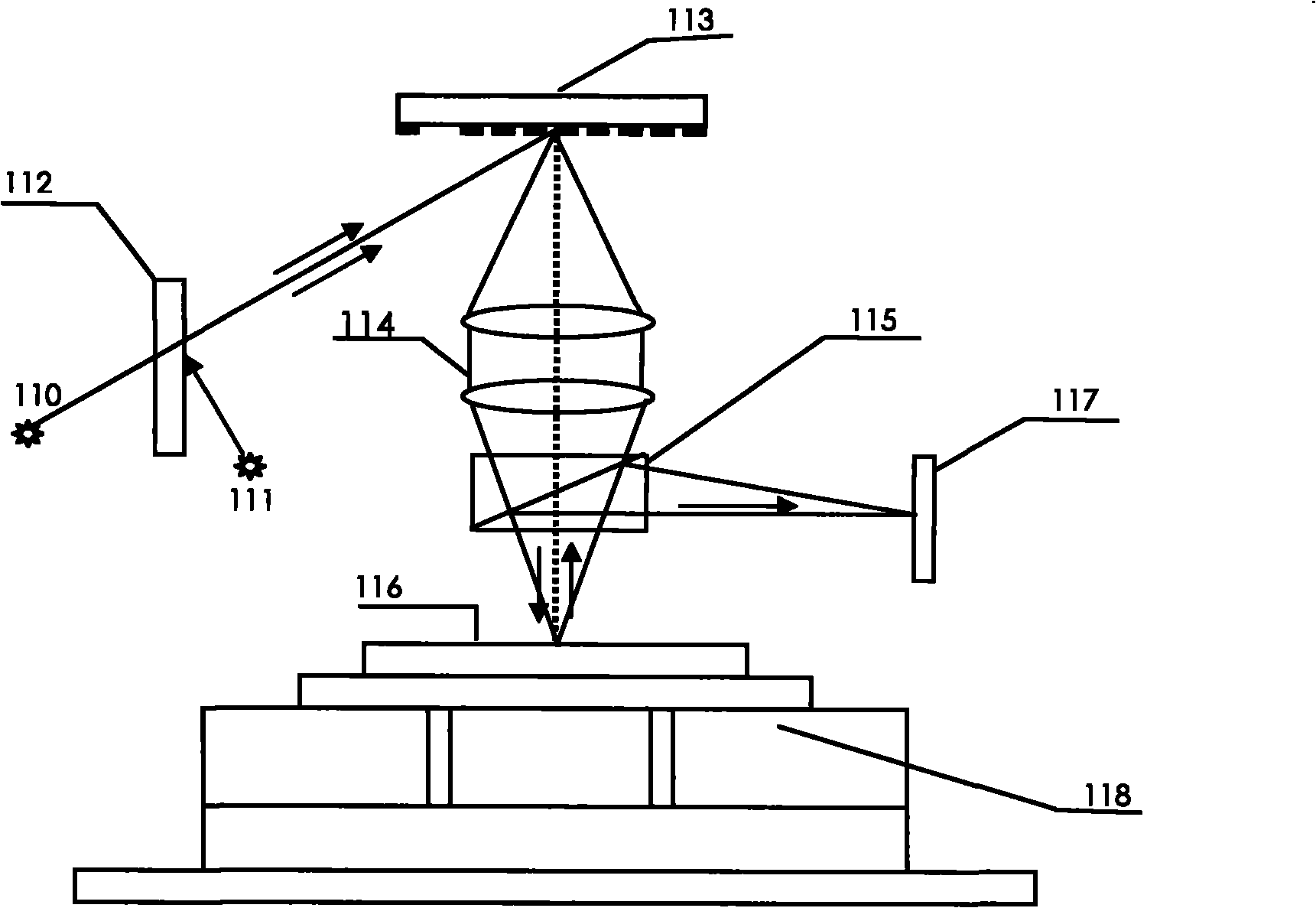

[0020] Such as figure 1 As shown, the maskless lithography alignment system of this embodiment includes an alignment bright light source 111, a first dichroic beam splitter 112, a digital micro mirror device (DMD) 113, a projection objective 114, and a second Dichroic beam splitter 115, silicon wafer 116, photoelectric coupling imaging device 117, workpiece stage 118; the first dichroic beam splitter 112 is located between the exposure light source 110 and the alignment light source 111, and the incident surface of the first dichroic beam splitter 112 receives Expose the exposure light beam of the light source 110, the dichroic dichroic surface of the first dichroic beam splitter 112 receives the alignment light output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com