Method for preparing polyacrylonitrile spinning solution

A technology of polyacrylonitrile spinning and acrylonitrile is applied in the direction of single-component synthetic polymer rayon, textile and papermaking, fiber chemical characteristics, etc. Achieving good technical effect and convenient material discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

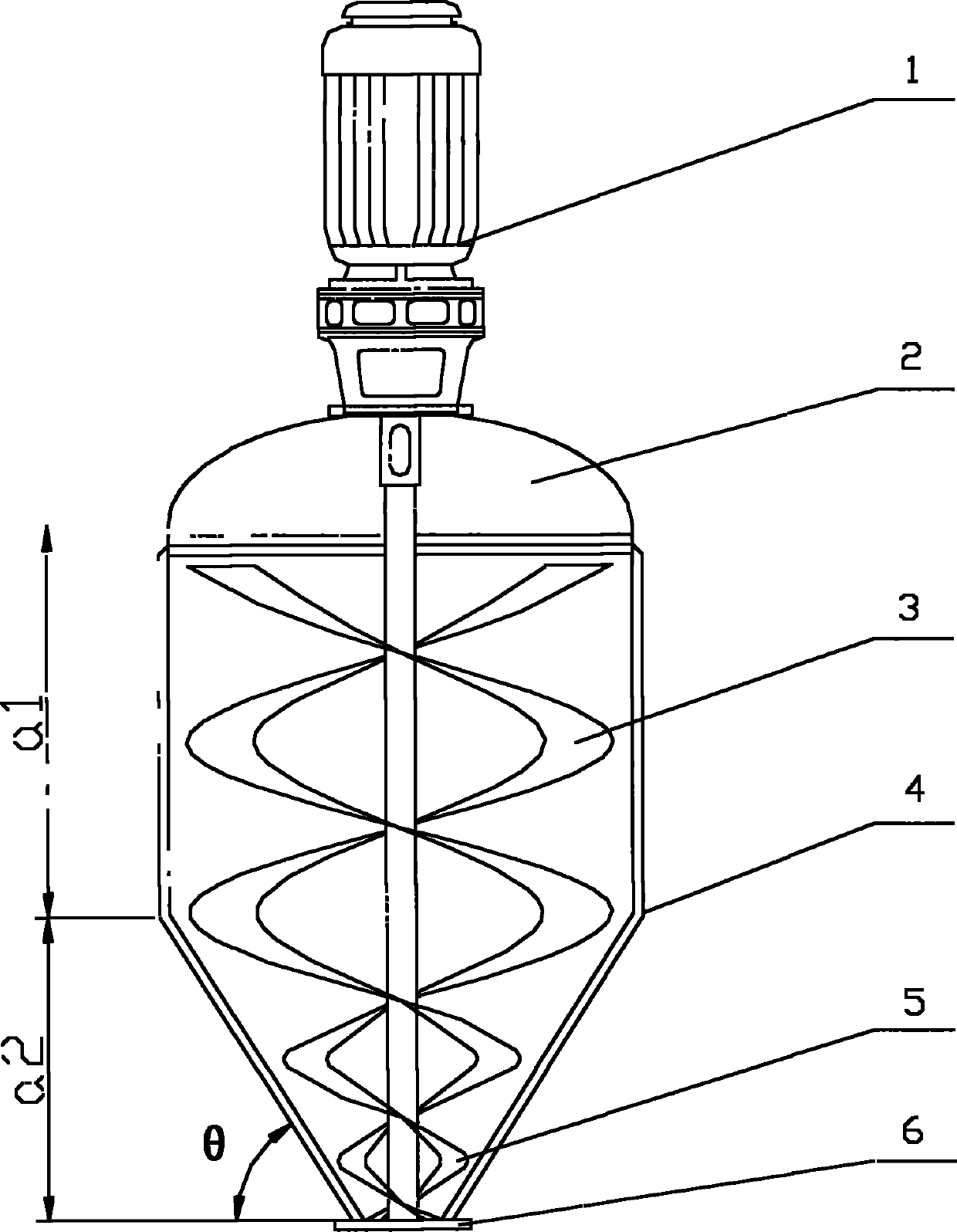

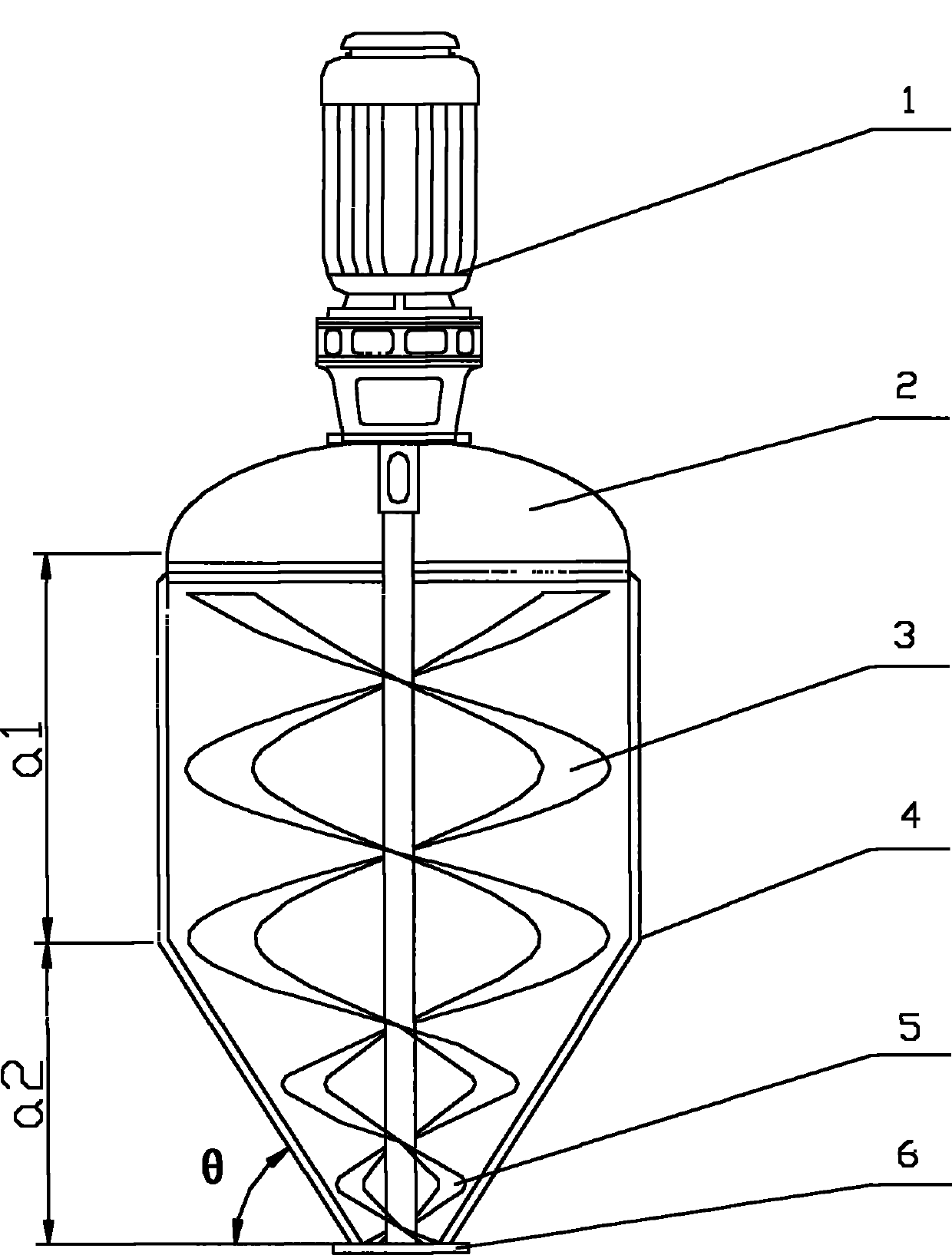

[0017] use figure 1 Described 10 liters of mechanically stirred tanks (the height of the round table part accounts for about 33% of the total tank height, the volume accounts for 30% of the total tank volume, and the inclination angle θ is 50 °, wherein the outer edge of the double-screw ribbon stirring blade and the inner wall of the reactor The distance is 10 millimeters), dimethyl sulfoxide (DMSO), acrylonitrile (AN), itaconic acid (IA), initiator azobisisobutyronitrile altogether 5 kilograms add in the reactor successively, and wherein ratio is dimethyl Base sulfoxide: acrylonitrile: itaconic acid=80: 19.6: 0.4, and the initiator consumption is 0.55% of the monomer. Stir until it becomes a uniform solution, first vacuumize the system with a vacuum pump, then protect it with nitrogen, slowly heat up to the target temperature, the initial solution is colorless and transparent, stir and react at 150 rpm, as the reaction time prolongs , the viscosity of the system increases g...

Embodiment 2

[0019] use figure 1 Described 10 liters of mechanically stirred tank (the height of the round table part accounts for about 40% of the total tank height, the volume accounts for about 35% of the total tank volume, and the inclination angle θ is 60°, wherein the outer edge of the double-screw ribbon agitator and the inner wall of the reactor The distance is 8 millimeters), dimethyl sulfoxide (DMSO), acrylonitrile (AN), itaconic acid (IA), methyl acrylate (MA), and initiator azobisisobutyronitrile in turn for a total of 5 kg Add it into the reaction kettle, wherein the ratio is dimethyl sulfoxide: acrylonitrile: itaconic acid: methyl acrylate = 80: 19.6: 0.2: 0.2, and the amount of the initiator is 0.6% of the monomer. Stir until it becomes a uniform solution, first vacuumize the system with a vacuum pump, then protect it with nitrogen, slowly heat up to the target temperature, the initial solution is colorless and transparent, stir and react at 150 rpm, as the reaction time pro...

Embodiment 3

[0021] use figure 1Described 10 liters of mechanically stirred tank (the height of the round table part accounts for about 25% of the total tank height, the volume accounts for about 28% of the total tank volume, and the inclination angle θ is 40°, wherein the outer edge of the double-screw ribbon agitator and the inner wall of the reactor The distance is 6 millimeters), dimethylsulfoxide (DMSO), acrylonitrile (AN), itaconic acid (IA), initiator azobisisoheptanonitrile total 5 kilograms are added in the reactor successively, and wherein ratio is Dimethyl sulfoxide: acrylonitrile: itaconic acid=82:17.6:0.4, the amount of initiator is 0.5% of the monomer. Stir until it becomes a uniform solution, first vacuumize the system with a vacuum pump, then protect it with nitrogen, slowly heat up to the target temperature, the initial solution is colorless and transparent, stir and react at 150 rpm, as the reaction time prolongs , the viscosity of the system rises gradually, the torque ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com