Production method for polymer lithium ion batteries of high performance and long service life

A lithium ion battery and a production method technology are applied in the field of lithium ion batteries to achieve the effects of ensuring service life and safety performance, avoiding short circuits and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

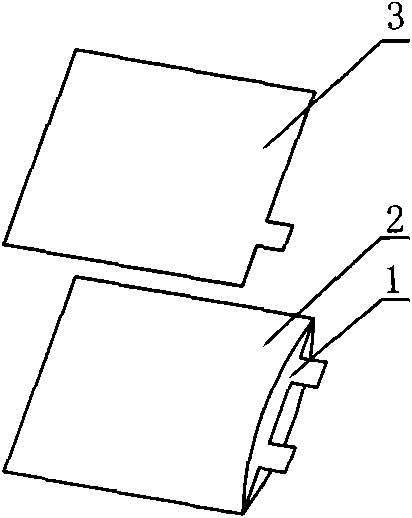

[0015] Example 1: In image 3 , Figure 4 , Figure 6 Middle: The positive electrode sheet 1 is installed in the diaphragm bag 2, and the positive electrode sheet 1 is in the shape of a rectangle. Iron Lithium (Li 2 FeSiO 4 ) represented by Li 2 MSiO 4 (M is Co, Ni, Fe, Mn and other transition metal elements) The new positive electrode material and its lithium-containing oxide, composite, conductive agent, and binder are made of two protruding tabs with the same shape and size. The surface of the diaphragm bag 2 is coated with a layer of PP, PE or PVDF2801, which is a copolymer of polyvinylidene fluoride and hexafluoropropylene, and a double-sided coated negative electrode sheet 3 is attached to the outer side of the diaphragm bag 2. The negative electrode sheet 3 is rectangular It is made of alloy materials, carbon-graphite materials, binders, and additives. There is a protruding tab on the top, which first constitutes the positive battery 7. A layer of double-sided coa...

Embodiment 2

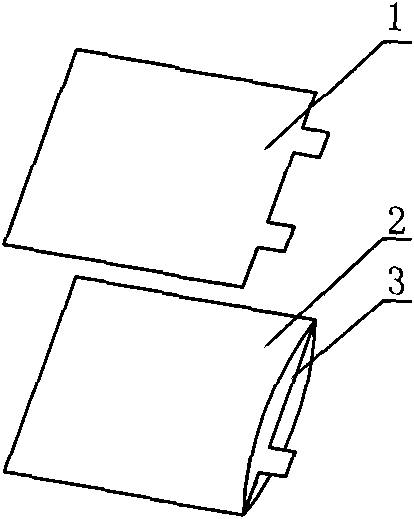

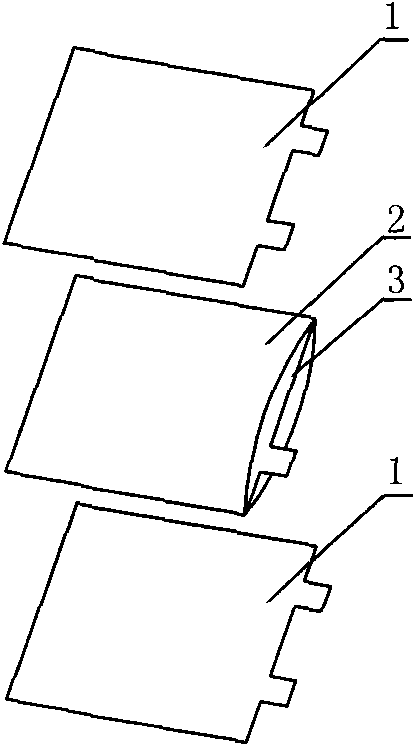

[0016] Example 2: In figure 1 , figure 2 , Figure 5 Middle: The negative electrode sheet 3 is installed in the diaphragm bag 2, and the negative electrode sheet 3 is in the shape of a rectangle, made of alloy materials, carbon-graphite materials, binders, and additives. There is a raised tab on the top, and the surface of the diaphragm bag 2 is coated A layer of PP, PE or PVDF2801, which is a copolymer of polyvinylidene fluoride and hexafluoropropylene, has a layer of double-sided coated positive electrode sheet 1 on the outer side of the diaphragm bag 2, which first constitutes the negative electrode single cell 5, and the positive electrode sheet 1 It is in a rectangular shape, made of lithium cobaltate or lithium manganate, lithium nickelate, ternary materials, lithium ferrous phosphate, lithium vanadium iron phosphate and lithium ferrous silicate (Li 2 FeSiO 4 ) represented by Li 2 MSiO 4 (M is Co, Ni, Fe, Mn and other transition metal elements) The new positive ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap