Method for improving selectivity of cis pinane prepared by alpha-pinene hydrogenation

A magnetic and nano-nickel technology, applied in the fields of hydrogenation to hydrocarbon production, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

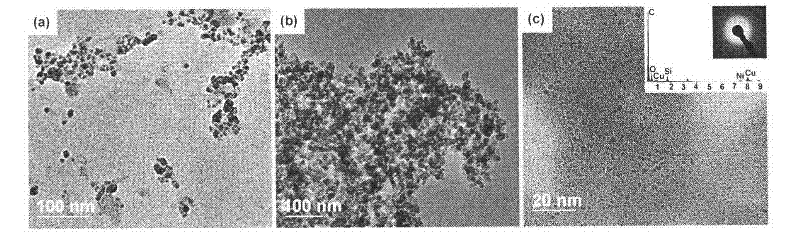

[0017] These examples illustrate the use of silica sol-supported amorphous Ni as precursor to magnetic Fe 3 o 4 As a carrier, nano-nickel catalysts with different compositions and needle-like morphology were prepared by adjusting the ratio of amorphous and crystalline Ni.

[0018] The first is the preparation of silica sol supported amorphous Ni. Prepare a certain concentration of KBH 4 The solution has a concentration of 0.1 to 2.0 mol / L, and is uniformly mixed with a certain amount of silica sol. Then prepare a certain concentration of nickel salt solution, the concentration is 0.02 ~ 2.83mol / L, nickel salt and KBH 4 The molar ratio is 1:2. Under a certain protective gas, drop the nickel salt solution into the above mixed solution at a certain speed (1-12mL / min), control the reaction temperature at 0-30°C, and react until no gas is produced. The product is amorphous Ni supported by silica sol, and it is used as the precursor of reducing crystalline nano-nickel. Then, p...

Embodiment 2

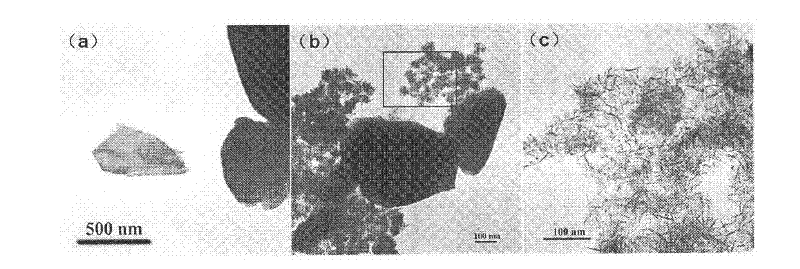

[0020] These examples illustrate the use of different meshes of magnetic Fe 3 o 4 The process of preparing needle-shaped nano-nickel catalyst with powder as carrier.

[0021] Using different meshes of magnetic Fe 3 o 4 (100 mesh, 200 mesh, 300 mesh, 600 mesh, 800 mesh) is carrier, according to the method among the embodiment 1, prepares the acicular nano-nickel catalyst. When using 600 mesh magnetic Fe 3 o 4 The catalyst prepared when used as a support is designated as AKT-2.

Embodiment 3

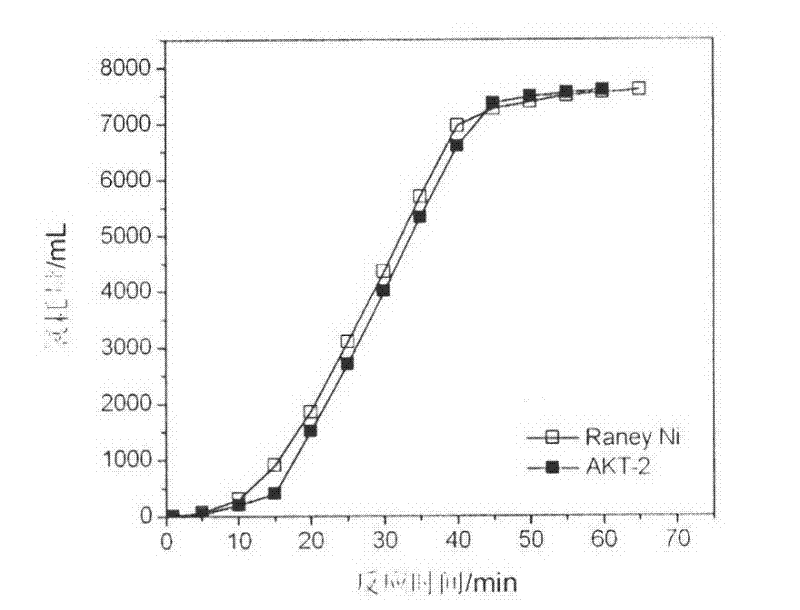

[0025] These examples illustrate the relationship between AKT-2 catalyst storage time and its catalytic activity when stored in absolute ethanol.

[0026] A follow-up test has been done on the preservation of the AKT-2 catalyst, and the results are as attached Figure 4 shown. After being sealed and stored at room temperature for 30 days, the conversion rate of the catalyst to raw materials and the selectivity to cis-pinane are well maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com