Molecular sieve P-IM-5 and its application in toluene alkylation reaction

A technology of IM-5 and toluene alkyl, applied in the field of IM-5 molecular sieves and catalysts prepared from the molecular sieves, can solve the problems of reduced activity, reduced selectivity of xylene, reduced acid strength, etc., to reduce side reactions and improve Effect of Toluene Conversion and Xylene Selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

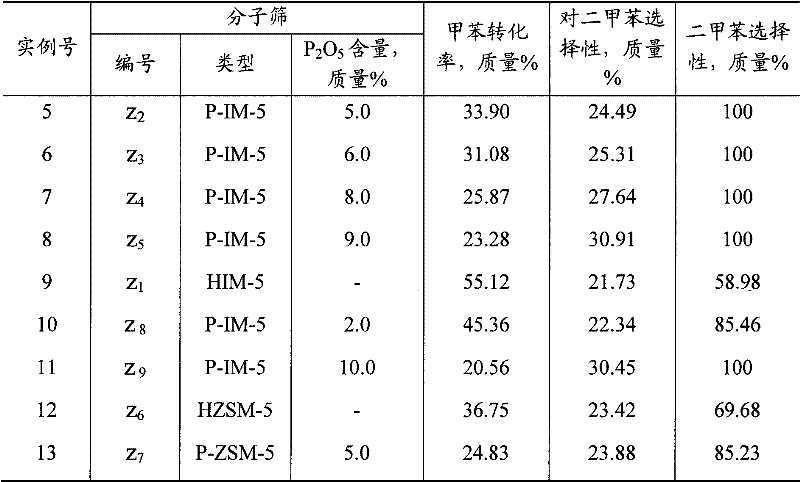

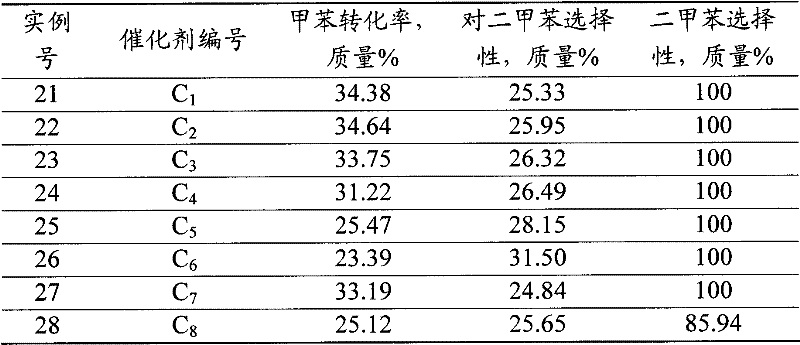

Examples

preparation example Construction

[0017] The preparation method of P-IM-5 described in the present invention is: introducing phosphorus element in the molecular sieve preparation process for modification, and the phosphorus-containing compound is selected from phosphoric acid, ammonium phosphate, ammonium hydrogen phosphate, ammonium dihydrogen phosphate, three Phenylphosphonium, Trimethyl Phosphate. The method of introducing can be dipping method, mechanical mixing method, preferably dipping method. During impregnation, the liquid / solid ratio of the phosphorus-containing compound solution to the H-IM-5 molecular sieve is 1-8ml / g, preferably 3-6ml / g, the impregnation time is 1-4 hours, and the impregnation temperature is 60-85°C. After impregnation, the solid is dried at 90-120°C and calcined at 450-550°C to obtain P-IM-5 molecular sieve.

[0018] The method for preparing the catalyst of the present invention is as follows: thoroughly mix and knead the P-IM-5 molecular sieve and the precursor of the binder, t...

example 1

[0023] Prepare the P-IM-5 molecular sieve of the present invention.

[0024] (1) Preparation of H-IM-5 molecular sieve

[0025] SiO 2 / Al 2 o 3 NaIM-5 molecular sieve with a molar ratio of 48.4 was ion-exchanged with ammonium nitrate solution with a concentration of 0.5 mol / L at 80° C. for 3 times, each time for 2 hours. The molecular sieve obtained after the exchange was washed with deionized water, dried at 90°C for 24 hours, and calcined at 500°C for 5 hours to obtain H-IM-5 molecular sieve z 1 , whose Na 2 The O content is less than 0.1% by mass.

[0026] (2) Preparation of P-IM-5 molecular sieve

[0027] The above-mentioned H-IM-5 molecular sieve was impregnated with ammonium dihydrogen phosphate solution with a concentration of 0.2mol / L at a liquid / solid ratio of 3.52ml / g at 80°C for two hours, dried at 90°C for 24 hours, and calcined at 500°C for 4 hours , to prepare phosphorus-modified P-IM-5 molecular sieve z 2 , whose P 2 o 5 The content is 5.0% by mass.

example 2

[0029] Prepare the P-IM-5 molecular sieve by the method for example 1, difference is that (2) step is impregnated with the ammonium dihydrogen phosphate solution of 0.2mol / L with the liquid / solid ratio of 4.23ml / g 1 Molecular sieve, P-IM-5 molecular sieve obtained after drying and roasting 3 , whose P 2 o 5 The content is 6.0% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com