Duplex deaerator

A deaerator and duplex technology, applied in the field of duplex deaerators, can solve problems such as explosion, catalyst bed overheating, catalyst damage, etc., and achieve the effects of avoiding damage, avoiding overheating phenomenon and preventing explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

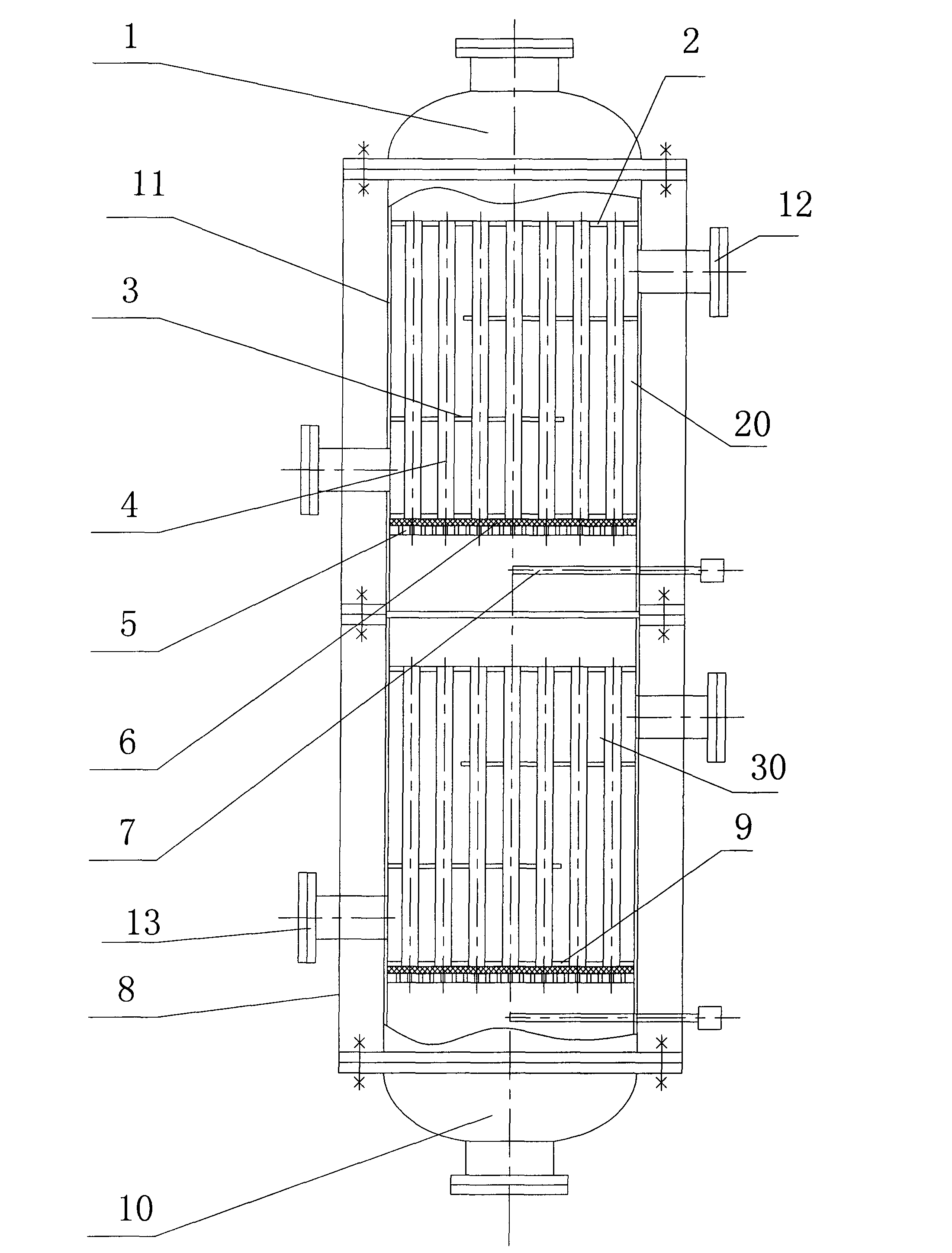

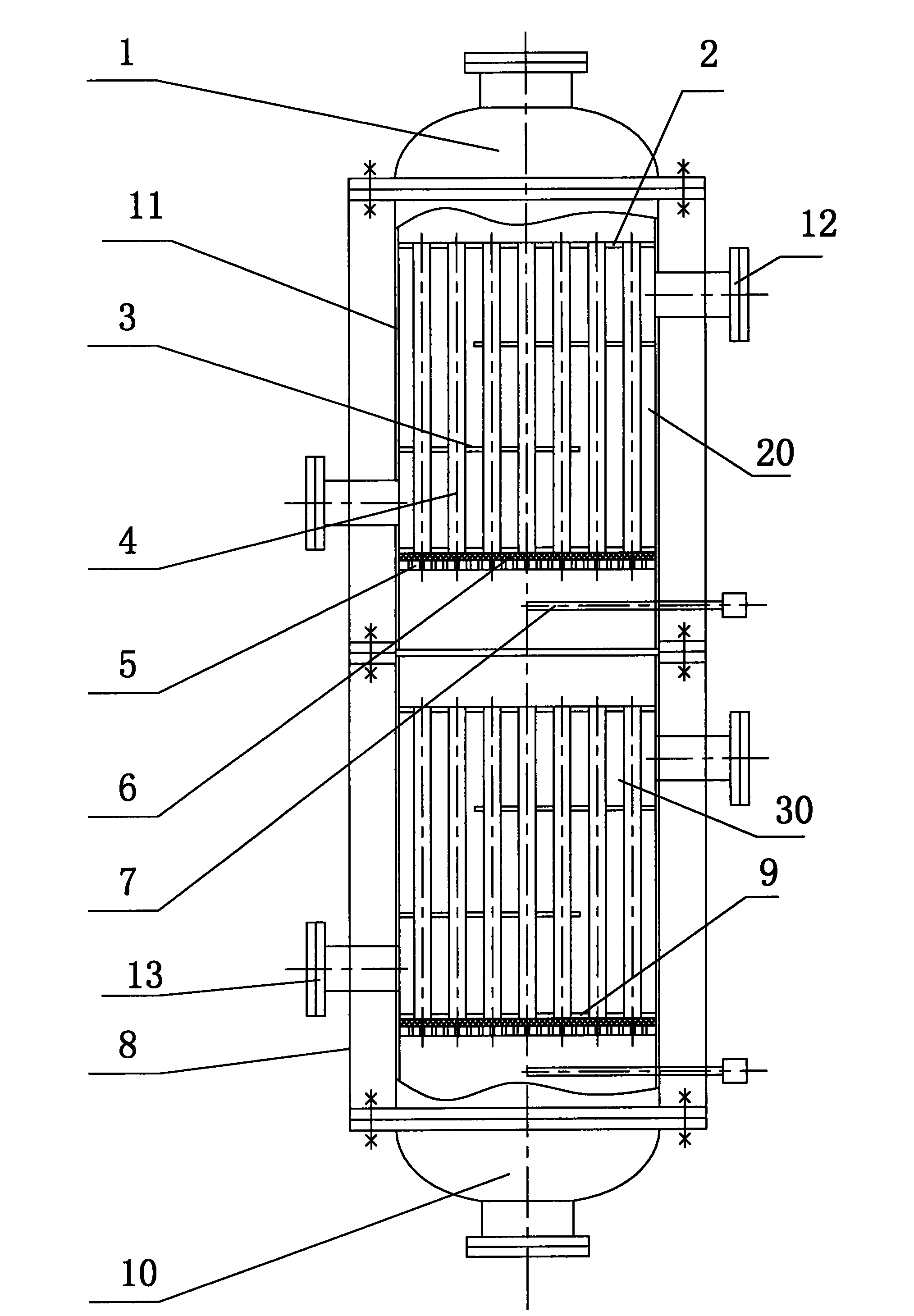

[0014] See figure 1 The compound deaerator includes two compound deaerator units 20, 30, a raw material gas inlet head (air distributor) 1, a product gas outlet head (air distributor) 10.

[0015] The two duplex deaerator units 20 and 30 have the same structure, and both include the shell 11, the upper flange 2, the lower flange 9, the column pipe 4, the stainless steel wire mesh 5, the sieve plate 6, and the thermocouple (thermometer) connection pipe 7, Insulation layer 8, baffle 3, etc. The lower end of the housing of the multiple deaerator unit 20 is connected to the upper end of the housing of the multiple deaerator unit 30.

[0016] The peripheries of the upper flange 2 and the lower flange 9 are respectively connected to the inner wall of the shell close to the upper and lower ends of the shell. The upper and lower ends of the tube 4 respectively pass through the upper flange and the lower flange, and each tube is in the circumferential direction. It is in sealed contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com