Anaerobic pyrolysis purification process

A purification process and pyrolysis technology, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, and petroleum industry, etc., can solve the problems of low utilization rate of resources, poor quality of straw gas, etc. The effect of reducing the design temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

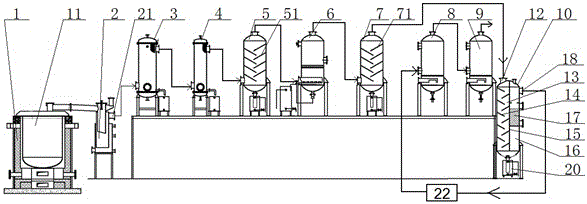

[0042] The anaerobic pyrolysis purification process includes the following steps in turn:

[0043] Gas generation step: put the formed straw sticks or other straw materials into the retort 11 first, then heat the straw sticks or other straw materials in the retort 11 by the pyrolysis furnace 1, and the straw sticks or other straw materials are High-temperature straw gas is generated after pyrolysis, wherein, the operation method for dry distillation 11 is as follows: firstly open the vent 21 of tar separator 2, then heat dry distillation kettle 11 for 2 hours to make the temperature reach 150°C, and then The discharge port 21 of the tar separator 2 is closed, then the discharge ports of No. 1 gas filter 8 and No. 2 gas filter 9 are opened, and the heating is continued for 1 hour to make the temperature rise to 250° C., then No. 1 gas filter 8 1. The discharge port of the No. 2 gas filter 9 is closed, and the Roots blower unit 22 is started again, and then the heating is contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com