Circulation cooling pipeline of three-level power module of integrated gate commutated thyristor (IGCT)

A commutating thyristor, power module technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of high heat dissipation efficiency, low operating noise, pollution, etc., to facilitate replacement and maintenance, improve heat dissipation efficiency, save energy The effect of capillary tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in combination with specific embodiments.

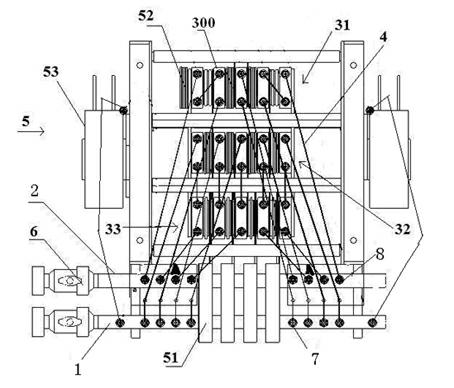

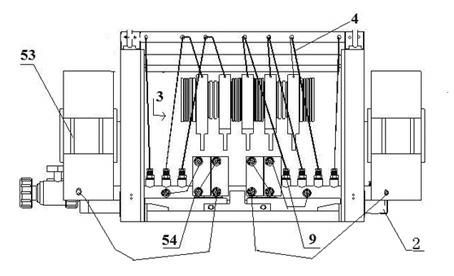

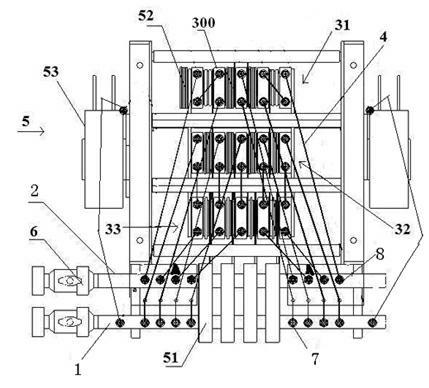

[0024] See figure 1 and figure 2 As shown, the water supply main tube 1 and the return water main tube 2 are arranged under the integrated gate commutation thyristor 51 of the integrated gate commutated thyristor three-level power module 5, and are distributed in random order; the water supply main tube 1 and the return water main tube 2 Arranged in parallel with the power string 52 of the integrated gate-commutated thyristor three-level power module 5, the structure of the circulation pipeline is compact, which is conducive to saving the circulation pipeline path; the same number of water supply pipes 1 and return water pipes 2 There are ten water supply interfaces 7 on the water supply main pipe 1 and ten return water interfaces 8 on the water return main pipe 2. One end of the water supply main pipe 1 and the return water main pipe 2 are respectively closed, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com