Spiral biomass pyrolysis reactor with drying function

A pyrolysis reactor and biomass pyrolysis technology, which is used in the fields of pyrolysis liquefaction, pyrolysis carbonization, and biomass pyrolysis gasification, which can solve the problem of limiting the pyrolysis capacity of fixed bed pyrolysis reactors and not being suitable for biomass. Pyrolysis liquefaction, uneven bed pyrolysis and other problems, to achieve the effect of increasing the pyrolysis processing capacity, simple structure, and realization of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

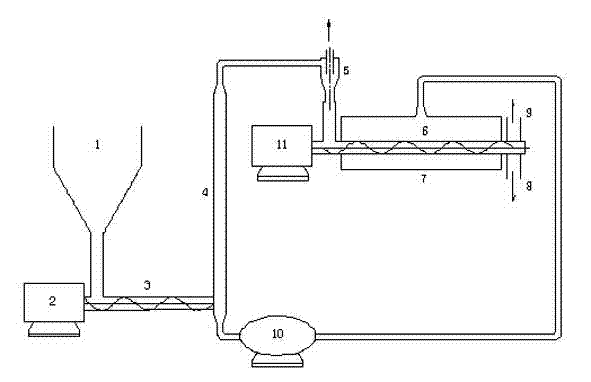

[0019] see figure 1 , The spiral biomass pyrolysis reactor with drying function includes barrel 1, first speed regulating motor 2, screw feeder 3, drying lifting cylinder 4, cyclone separator 5, spiral pyrolysis reactor 6 , combustion heating chamber 7, pyrolysis charcoal outlet 8, pyrolysis gas outlet 9, induced draft fan 10 and second speed regulating motor 11.

[0020] The diameter of drying lifting tube 4 is 100 millimeters, and height is 2.5 meters.

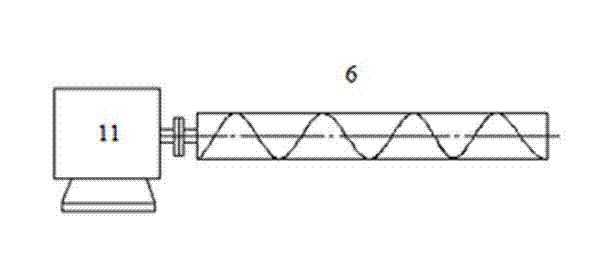

[0021] Spiral pyrolysis reactor 6 is a single-screw helical propulsion mechanism (see figure 2 ), wherein the length of the screw is 1.2 mm, the major diameter of the screw thread is 80 mm, the minor diameter of the screw thread is 60 mm, and the pitch is 45 mm.

[0022] The barrel 1 is located above the inlet of the screw feeder 3, and the outlet of the screw feeder 3 is connected to the lower side of the vertical drying lifting drum 4; the bottom of the drying lifting drum 4 is connected to the side of the induced draft...

Embodiment 2

[0025] see figure 1 , The spiral biomass pyrolysis reactor with drying function includes barrel 1, first speed regulating motor 2, screw feeder 3, drying lifting cylinder 4, cyclone separator 5, spiral pyrolysis reactor 6 , combustion heating chamber 7, pyrolysis charcoal outlet 8, pyrolysis gas outlet 9, induced draft fan 10 and second speed regulating motor 11.

[0026] The diameter of drying lifting tube 4 is 100 millimeters, and height is 2.5 meters.

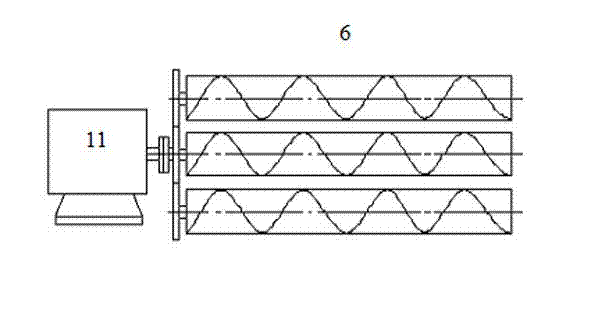

[0027] The spiral pyrolysis reactor 6 is a spiral propulsion mechanism composed of three screws (see image 3 ), wherein the length of the screw is 1.2 mm, the major diameter of the screw thread is 80 mm, the minor diameter of the screw thread is 60 mm, and the pitch is 45 mm.

[0028] The barrel 1 is located above the inlet of the screw feeder 3, and the outlet of the screw feeder 3 is connected to the lower side of the vertical drying lifting drum 4; the bottom of the drying lifting drum 4 is connected to the side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com