Colored laminate metal sheet for containers

A metal plate and coloring layer technology, applied in the field of colored laminated metal plates for containers, can solve the problems of requiring a lot of time for cleaning and hindering productivity, and achieve the effect of maintaining design and excellent rust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

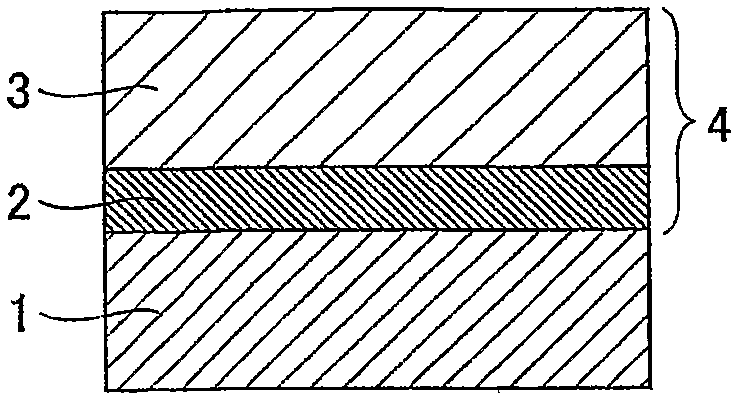

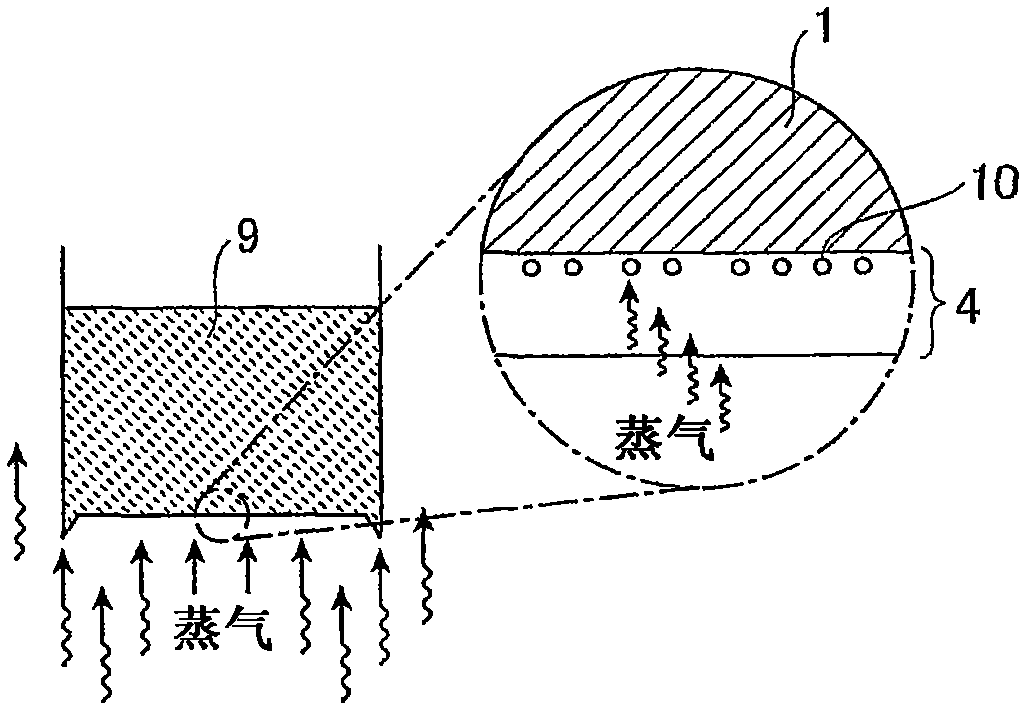

[0105] [Manufacture of lamination film]

[0106] Tables 1 to 6 show the configurations of the resin film and the colored adhesive layer laminated on the resin film.

[0107] The components for coloring the pressure-sensitive adhesive layer were mixed under the conditions shown in Tables 1 to 6, and the resulting mixture was dissolved in a mixed solvent of toluene and methyl ethyl ketone to prepare a coating liquid. Apply the above-mentioned coating solution to one surface of the resin film shown in Table 1 to Table 6 using a gravure coating roll coater, and then dry it at 80 to 120°C to form a colored bond on the surface of the resin film. agent layer to produce a laminating film.

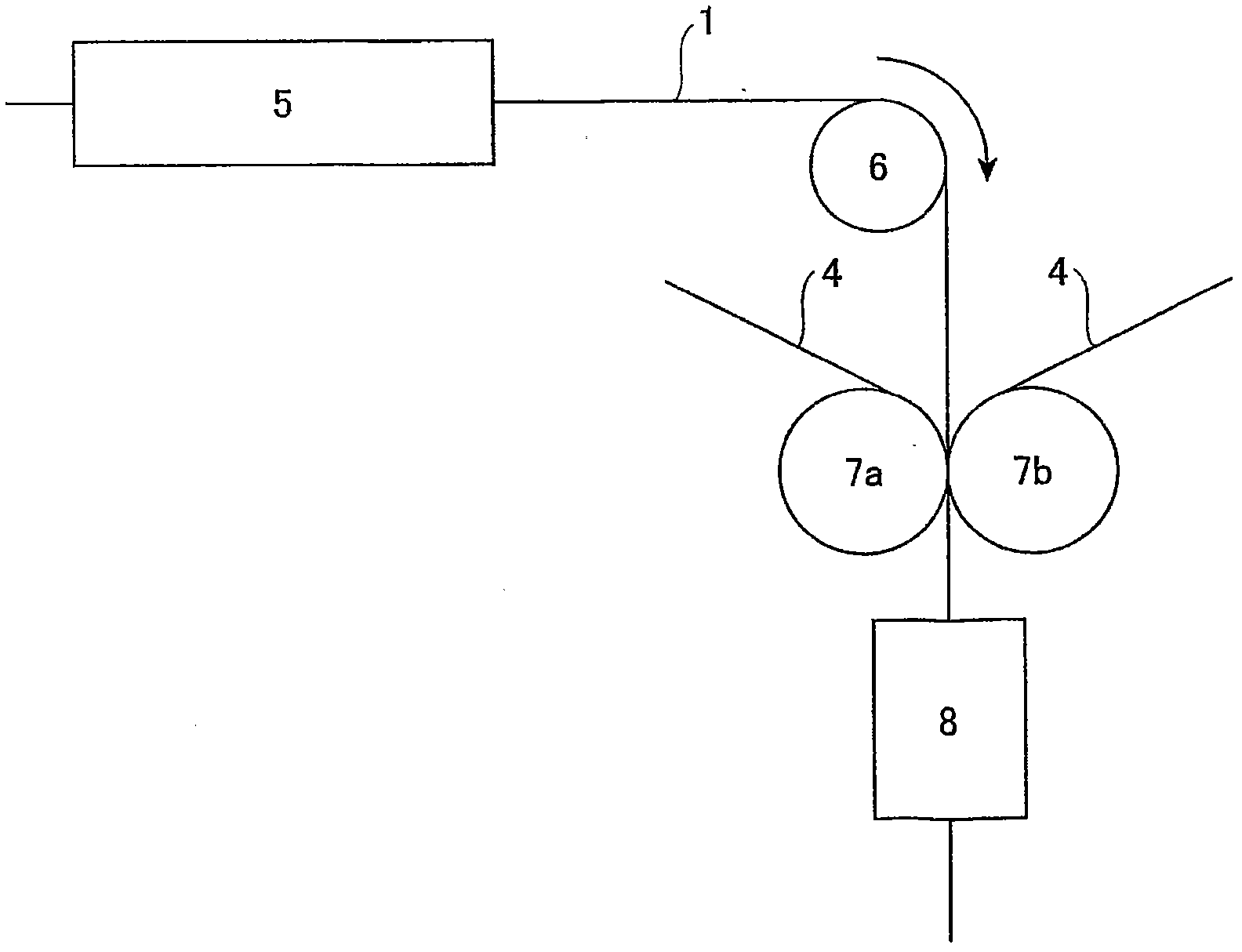

[0108] [Manufacture of colored laminated steel sheets for containers]

[0109] As the metal plate, a chrome-plated steel sheet (TFS: tin-free sheet) was used. After degreasing and pickling cold-rolled steel sheets with a thickness of 0.21 mm, use CrO-containing 3 , F - and SO 4 2- The chromi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com