Method and device for preparing faintly acid disinfectant fluid by diaphragm-free electrolysis

A non-diaphragm, weakly acidic technology, applied in the field of electrochemistry, can solve the problems of high manufacturing and maintenance costs, easy failure, large power consumption, etc., and achieve high practical value, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

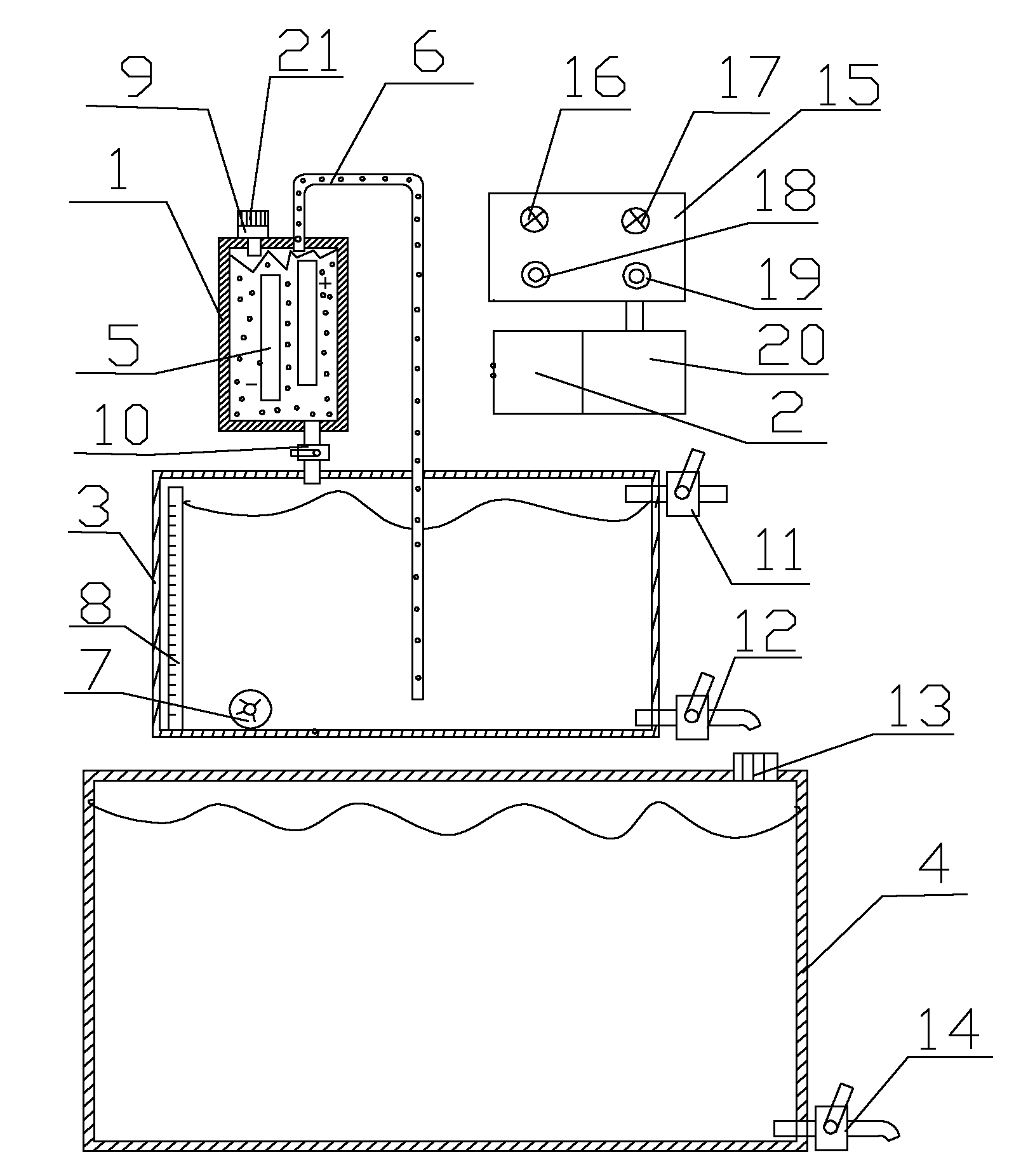

[0021] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0022] A device for producing weakly acidic disinfectant water by electrolysis without a diaphragm, comprising an electrolytic cell 1, a power source 2 and a first dilution tank 3, the electrolytic cell 1 is placed above the first dilution tank 3 and the two can be communicated, the power source 2 and the first dilution tank 3 are connected. The two electrode plates 5 placed in the electrolytic tank 1 are connected, the electrolytic tank 1 is a chamber structure, and there is no diaphragm between the two electrode plates 5 . Below the first dilution tank 3, there is also a second dilution tank 4 which can dilute the strong acid solution in the first dilution tank 3 again. It also includes a chlorine-containing gas collection pipe 6 , the upper end of which is in communication with the electrolytic cell 1 , and the lower end is in communication with the first dilution tank 3 . A stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com