Skull defect restoration titanium mesh with nonsticking coating and preparation method thereof

An anti-adhesion coating and anti-adhesion coating technology, which is applied in coatings, medical science, prostheses, etc., can solve problems such as the inability to overcome the adhesion of meninges and skull defect repair materials, so as to avoid adhesion, avoid direct contact, no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

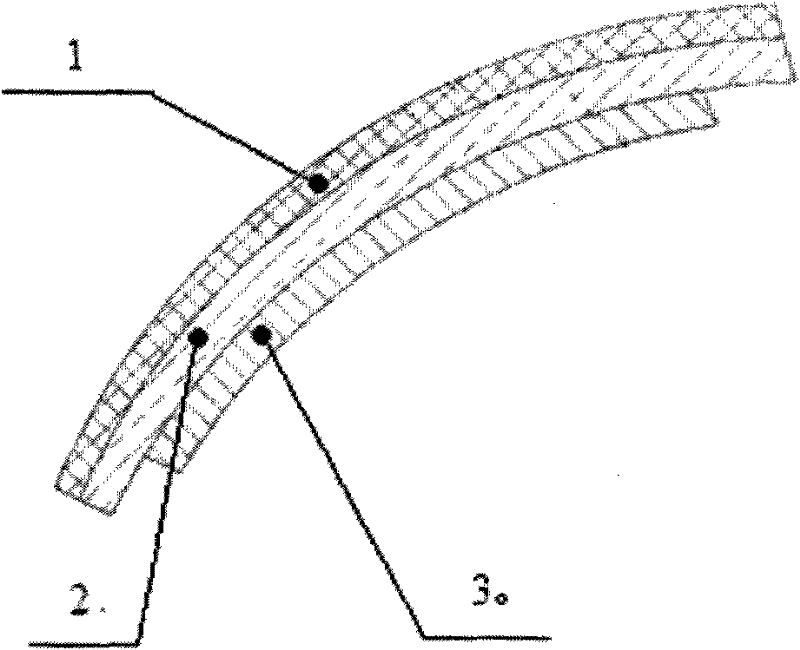

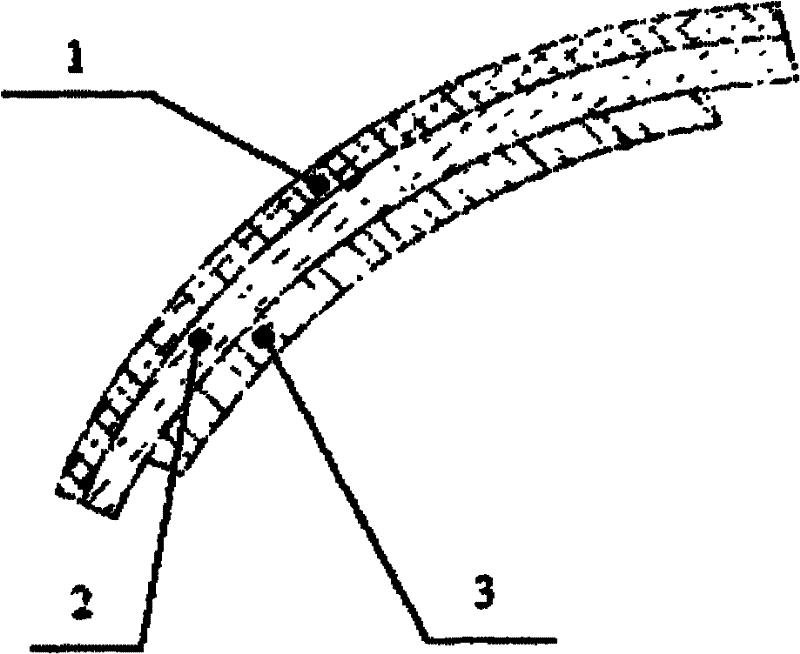

Image

Examples

Embodiment 1

[0020] (1) preparation concentration is the polybutylmethacrylate tetrahydrofuran solution of 5wt%, adopts the method for spraying, coats the bottom layer on the inner surface of the titanium net, medium flow rate 2ml / min, spraying time 120 seconds, dry, in the titanium net Form a bottom layer on the surface, dry at 30°C for 24 hours;

[0021] (2) Prepare a hyaluronic acid aqueous solution with a concentration of 15wt%, and apply it on the bottom layer by spraying, with a medium flow rate of 2ml / min and a spray time of 120 seconds, then dry it in the air and dry it at 20°C for 12 hours, so that the bottom layer A firm soft hyaluronic acid layer is formed on the surface to obtain the titanium mesh for repairing skull defects with an anti-stick coating.

Embodiment 2

[0023] (1) preparation concentration is the glycolide dimethylformamide solution of 1wt%, adopts the method for spraying, coats the bottom layer on the inner surface of the titanium mesh, medium flow rate 5ml / min, spraying time 180 seconds, dry in the air, on the titanium mesh Form a bottom layer on the inner surface, dry at 35°C for 30 hours;

[0024] (2) Prepare a hyaluronic acid aqueous solution with a concentration of 2wt%, and apply it on the bottom layer by spraying, with a medium flow rate of 5ml / min and a spraying time of 150 seconds, dry it in the air, and dry it at 25°C for 24 hours, so that the bottom layer A firm soft hyaluronic acid layer is formed on the surface to obtain the titanium mesh for repairing skull defects with an anti-stick coating.

Embodiment 3

[0026] (1) Prepare a sodium alginate aqueous solution with a concentration of 10 wt%, and apply a bottom layer on the inner surface of the titanium mesh by spraying, with a medium flow rate of 1ml / min, spray for 60 seconds, and dry to form a bottom layer on the inner surface of the titanium mesh , dried at 35°C for 48 hours;

[0027] (2) Prepare a hyaluronic acid aqueous solution with a concentration of 10wt%, and apply it on the bottom layer by spraying, with a medium flow rate of 2ml / min and a spray time of 120 seconds, then dry it in the air and dry it at 20°C for 12 hours, so that the bottom layer A firm soft hyaluronic acid layer is formed on the surface to obtain the titanium mesh for repairing skull defects with an anti-stick coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com