Composite material coated with SiC-Fe based alloy layer and preparation method of composite material

A composite material and base alloy technology, applied in the direction of metal material coating process, metal layered products, chemical instruments and methods, etc., can solve the problem of high brittleness of composite material coating, inability to adjust coating performance, and increased brittleness of cladding layer. and other problems, to achieve the effect of high cost performance, low cost, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

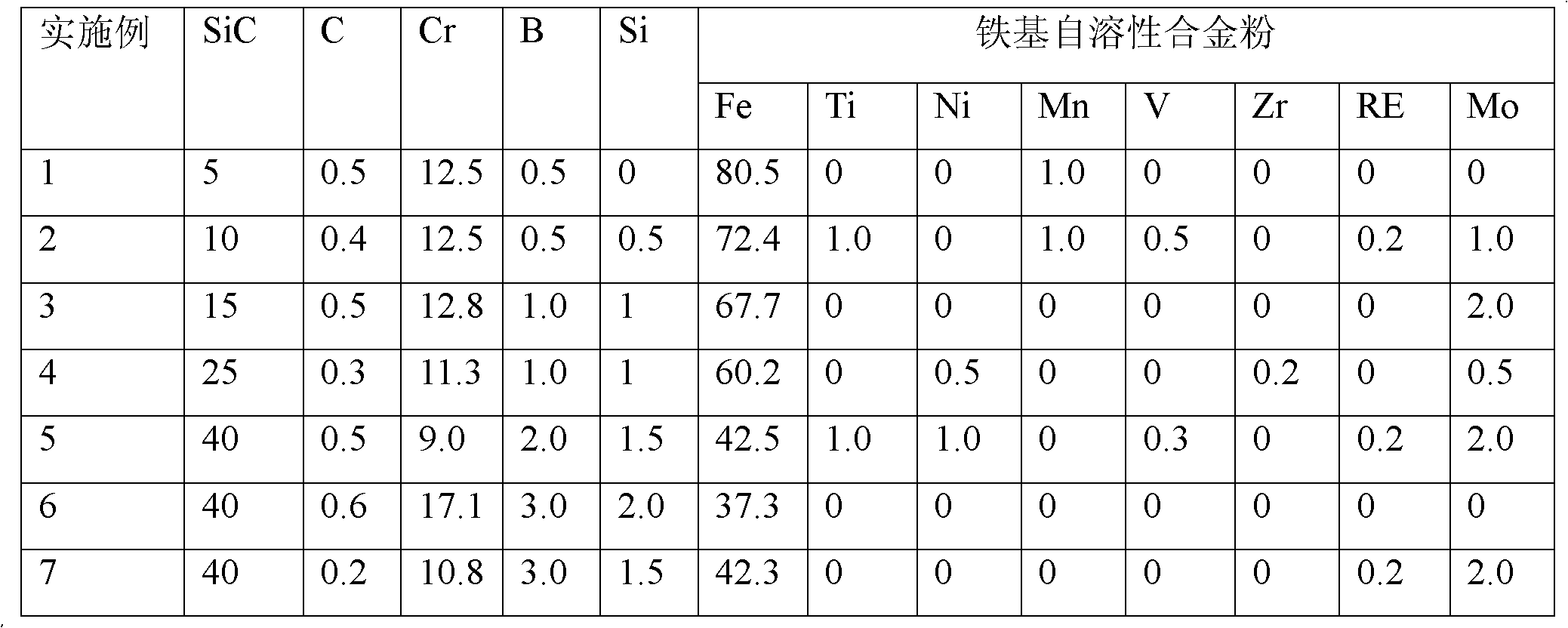

[0025] The composite material covered with SiC-Fe-based alloy layer in this embodiment is coated with SiC-Fe-based alloy layer on the surface of steel substrate; wherein the steel substrate is carbon steel with a carbon content of 0.2-0.7wt%, SiC The composition of the raw materials of the -Fe-based alloy layer is shown in Table 1 in terms of mass percentage. The SiC powder has a particle size of 50-80 μm, and the iron-based self-dissolving alloy powder has a particle size of 45-109 μm.

[0026] The preparation method of the composite material covered with the SiC-Fe-based alloy layer in this embodiment is to mix the iron-based self-dissolving alloy powder and SiC powder and apply it to the surface of the steel substrate by plasma spray welding to form a composite cladding layer. to bond it to the steel substrate.

[0027] Surfacing welding process parameters are as follows: current 130A, walking speed 90mm / min, swing frequency 22min -1 , swing width 20mm, Fe-based alloy pow...

Embodiment 2

[0029] The composite material covered with SiC-Fe-based alloy layer in this embodiment is coated with SiC-Fe-based alloy layer on the surface of the steel substrate; wherein the steel substrate is an alloy steel with a carbon content of 0.2-0.7wt%, SiC- The composition of the raw materials of the Fe-based alloy layer by mass percentage is shown in Table 1. The SiC powder has a particle size of 50-80 μm, and the iron-based self-dissolving alloy powder has a particle size of 45-109 μm.

[0030] The preparation method of the composite material covered with the SiC-Fe-based alloy layer in this embodiment is to mix the iron-based self-dissolving alloy powder and SiC powder and apply it to the surface of the steel substrate by plasma spray welding to form a composite cladding layer. to bond it to the steel substrate.

[0031] Surfacing welding process parameters are as follows: current 130A, walking speed 90mm / min, swing frequency 22min -1 , swing width 20mm, Fe-based alloy powder...

Embodiment 3

[0033] The composite material covered with SiC-Fe-based alloy layer in this embodiment is coated with SiC-Fe-based alloy layer on the surface of steel substrate; wherein the steel substrate is carbon steel with a carbon content of 0.2-0.7wt%, SiC The composition of the raw materials of the -Fe-based alloy layer is shown in Table 1 in terms of mass percentage. The particle size of the SiC powder is 50-80 μm, and the particle size of the iron-based self-dissolving alloy powder is 45-109 μm.

[0034] The preparation method of the composite material covered with the SiC-Fe-based alloy layer in this embodiment is to mix the iron-based self-dissolving alloy powder and SiC powder and apply it to the surface of the steel substrate by plasma spray welding to form a composite cladding layer. to bond it to the steel substrate.

[0035] Surfacing welding process parameters are as follows: current 130A, walking speed 90mm / min, swing frequency 22min -1 , swing width 20mm, Fe-based alloy p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com