Method for preparing ethylene glycol monopropyl ether

A technology of ethylene glycol monopropyl ether and n-propanol, which is applied to the preparation of ether from alkylene oxide, ether preparation, chemical instruments and methods, etc., to achieve the effects of easy operation and control, high catalyst activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

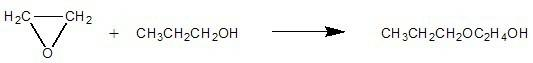

Image

Examples

Embodiment 1

[0024] Put 0.86g methane disulfonate and 750g n-propanol into a 1L stainless steel external circulation reactor, fully replace the air in the kettle with nitrogen, start the reactor, and add 110g ethylene oxide dropwise at 130-150℃ , And pass cooling water into the cooling coil in the kettle to remove the reaction heat, keep the pressure at 0.35-0.45Mpa, after the addition, cool the discharge, and then remove the n-propanol on a 20 mm × 700 mm rectification column. Perform vacuum distillation to obtain the target product, ethylene glycol monopropyl ether. The analysis proved that the conversion rate of ethylene oxide reached 100%, and the yield of ethylene glycol monopropyl ether was 97%.

Embodiment 2

[0026] Put 0.78g of methyl disulfonate and 705g of n-propanol into a 1L stainless steel external circulation reactor, fully replace the air in the kettle with nitrogen, start the reactor, and add 110g of ethylene oxide dropwise at 130-150℃ , And pass cooling water into the cooling coil in the kettle to remove the reaction heat, keep the pressure at 0.35-0.45Mpa, after the addition, cool the discharge, and then remove the n-propanol on a 20 mm × 700 mm rectification column. Perform vacuum distillation to obtain the target product, ethylene glycol monopropyl ether. The analysis proved that the conversion rate of ethylene oxide reached 100%, and the yield of ethylene glycol monopropyl ether was 95%.

Embodiment 3

[0028] Put 0.65g methyl disulfonate and 675g n-propanol into a 1L stainless steel external circulation reactor, fully replace the air in the kettle with nitrogen, start the reactor, and add 110g ethylene oxide dropwise at 130-150℃ , And pass cooling water into the cooling coil in the kettle to remove the reaction heat, keep the pressure at 0.35-0.45Mpa, after the addition, cool the discharge, and then remove the n-propanol on a 20 mm × 700 mm rectification column. Perform vacuum distillation to obtain the target product, ethylene glycol monopropyl ether. Analysis proved that the conversion rate of ethylene oxide reached 100%, and the yield of ethylene glycol monopropyl ether was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com