Method for extracting forsythin and forsythoside from forsythia leaves

A crude technology of forsythiaside and forsythiaside, which is applied in the field of natural product separation, can solve the problem that forsythin and forsythiaside cannot be simultaneously obtained by extracting and separating forsythin and forsythiaside at the same time. Effective ingredients, hydrolysis and destruction of Forsythia leaves, etc., to achieve the effect of simple method, low production cost and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

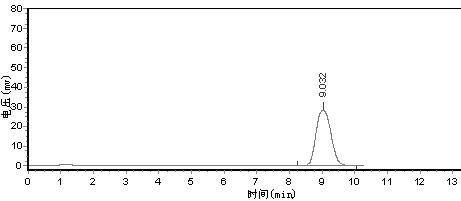

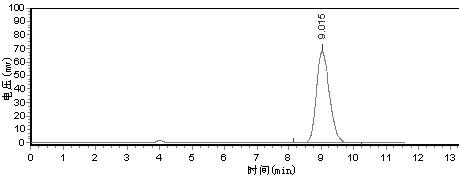

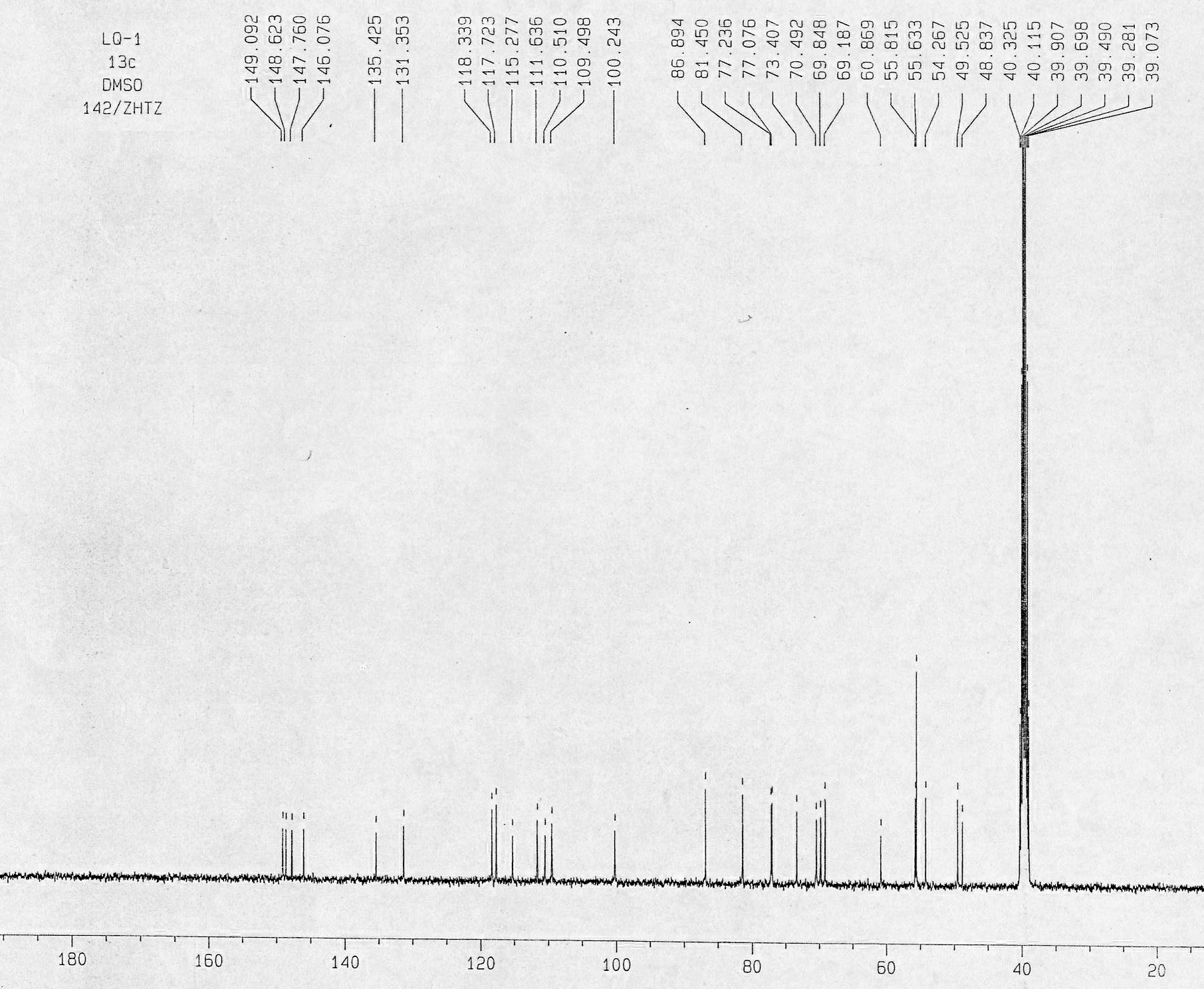

Image

Examples

Embodiment 1

[0032] A method for extracting forsythin and forsythiaside from forsythia leaves, the method comprising the steps of:

[0033] ①Extraction: Add 5kg of forsythia leaves into water at 80°C (50kg of water) for ultrasonic extraction for 1 hour, ultrasonic power 20KHz, and extract twice;

[0034] ②Separation: Combine the extracts obtained twice, filter and separate to discard the residue, concentrate the filtrate under reduced pressure (the volume ratio of the filtrate before and after concentration is 8:1), let it stand at room temperature for 15 hours, and then filter and separate the precipitate and the water layer under normal pressure. The precipitate is The crude extract of forsythin, the aqueous layer is the crude extract of forsythin;

[0035] ③ Refined Forsythin: Dry the crude extract of Forsythin, then mix 200g of the crude extract of Forsythin with ethyl acetate at a weight ratio of 1:6, then reflux extraction at 55°C for 2 times, each time for 40min , combined the ethy...

Embodiment 2

[0038] A method for extracting forsythin and forsythiaside from forsythia leaves, the method comprising the steps of:

[0039] ①Extraction: Add 10kg of forsythia leaves to 55°C water (160kg of water) for extraction, 1.5h each time, 3 times;

[0040] ②Separation: Combine the extracts obtained three times, filter and separate at normal pressure to discard the residue, concentrate the filtrate under reduced pressure (the volume ratio of the filtrate before and after concentration is 12:1), let it stand at room temperature for 48 hours, and then centrifuge at 3000r / min high-speed centrifuge to separate the precipitate and In the water layer, the precipitate is the crude extract of forsythin, and the water layer is the crude extract of forsythin;

[0041] ③ Refined forsythin: dry the crude extract of forsythin, then mix the dried 380g crude extract of forsythin with ethyl acetate at a weight ratio of 1:4, then reflux extraction at 60°C for 2 times, each time for 30 minutes , combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com