Process for manufacturing thermoplastic urethane (TPU) by utilizing waste spandex fiber

A technology of thermoplastic polyurethane and spandex waste silk, which is applied in the technical field of manufacturing thermoplastic polyurethane TPU, can solve the problems such as unclear instructions for manufacturing thermoplastic polyurethane TPU and degradation agent G, and the inability to implement spandex waste silk, etc., so as to achieve simple operation process and Economic and environmental benefits, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

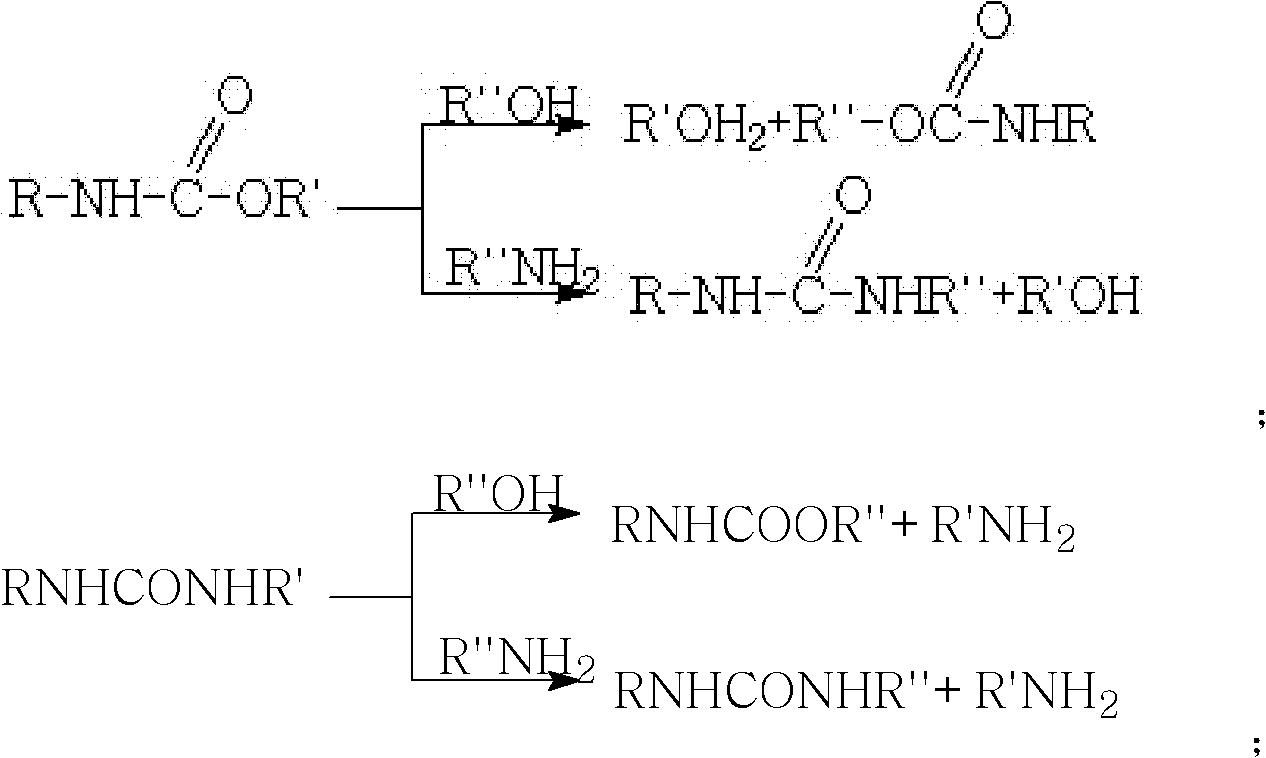

Method used

Image

Examples

Embodiment 1

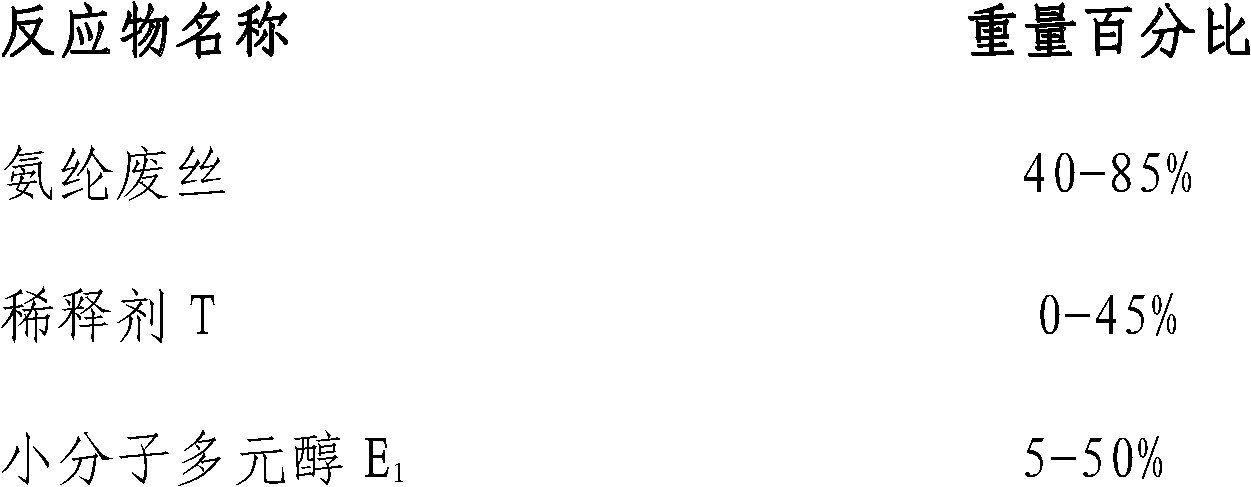

[0030] Select the following formula: spandex waste silk 50%, degradation agent G 0.52%, small molecule polyol E 1 1,4-Butanediol BDO 49.48%.

[0031] The following process steps are adopted: (1) select spandex waste silk, cut it into a thickness less than 1 cm, and then put it in an iron frame and put it in a 70°C blast high-dry oven for 8 hours, (2) add BDO to the reaction kettle , stirred, nitrogen gas was introduced at a speed of 5 L / min, and the temperature began to rise after 10 minutes. When the temperature reached 80°C, waste silk was added. Pay attention to the change of current, if the current is too high, stop adding waste silk, and add degradation agent after the temperature rises. When the temperature is 120°C, add degradation agent G for the first time, lock the lid, heat up and degrade for 30 minutes, then add waste silk again, and add degradation agent G for the second time after adding waste silk. Maintain the temperature at 140-150°C for 90 minutes to degra...

Embodiment 2

[0033] Select the following formula: spandex waste silk 45%, degradation agent G 1.2%, thinner T (low molecular polyether polyol) 42.8%, small molecule polyol E 1 1,4-Butanediol BDO 11%.

[0034] The following process steps are adopted: (1) select the spandex waste silk, cut it into a thickness less than 1 cm, and then put it in an iron frame and put it in a 70°C high-air blast oven for drying for 8 hours; (2) mix BDO and thinner T is added to the reactor, then stirred and nitrogen gas is introduced at a speed of 5L / min, and the temperature starts to rise after 10 minutes. When the temperature reaches 80°C, add waste silk. When the temperature is 120°C, add degradation agent G for the first time and lock it. After the lid is degraded at 150°C for 30 minutes, waste silk is added. After the waste silk is added, the degradation agent G is added for the second time. Maintain the temperature at 140-150°C for 120 minutes and degrade for 120 minutes. (3) When sampling and measuring ...

Embodiment 3

[0036] Select the following formula: spandex waste silk 65%, degradation agent G 3%, thinner T (containing carbonyl compound) 25%, small molecule polyol E11, 4-butanediol BDO 7%.

[0037] The following process steps are adopted: (1) select the spandex waste silk, cut it into a thickness less than 1 cm, and then put it in an iron frame and put it in a 70°C high-air blast oven for drying for 8 hours; (2) mix BDO and thinner T is added to the reactor, then stirred and nitrogen gas is introduced at a speed of 5L / min, and the temperature starts to rise after 10 minutes. When the temperature reaches 80°C, add waste silk. When the temperature is 120°C, add degradation agent G for the first time and lock it. After the lid is degraded at 135°C for 30 minutes, then add waste silk. After the waste silk is added, add degradation agent G for the second time. Maintain the temperature at 130-140°C for 90 minutes, then degrade at 110°C, vacuum negative pressure 0.98MPa, pump for 20 minutes, (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com