Surface modification method of multi-walled carbon nanotubes

A technology of multi-walled carbon nanotubes and surface modification, which is applied in the field of surface modification of multi-walled carbon nanotubes. The effect of detailed and accurate value and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with accompanying drawing:

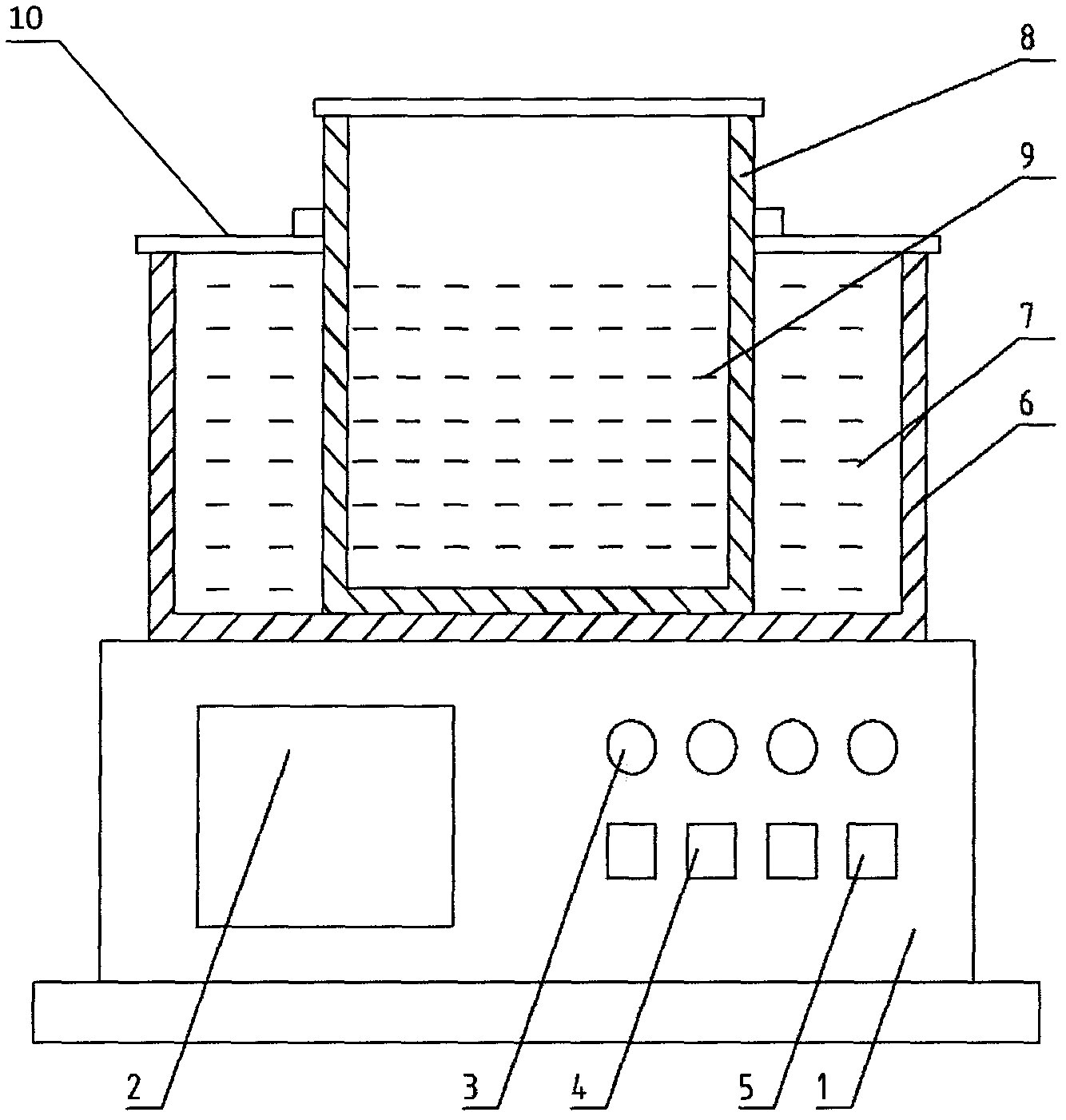

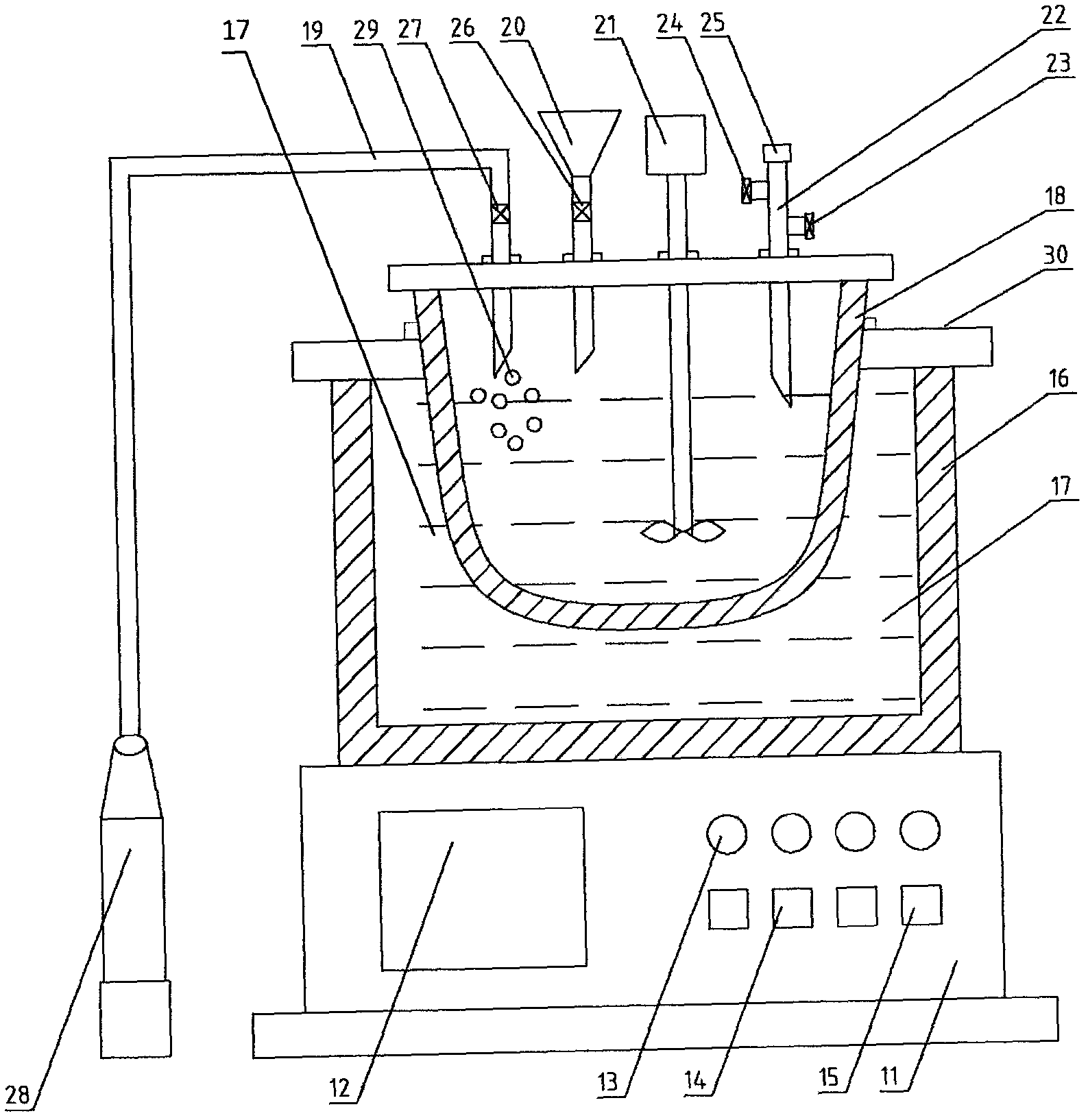

[0073] figure 1 As shown in the figure, it is a state diagram of multi-walled carbon nanotubes dispersed and coated, and the positions of each part must be correct, according to the amount and ratio, and operate in sequence.

[0074] The amount of chemical substances used in the preparation is determined according to the pre-set range, in grams, milliliters, centimeters 3 is the unit of measurement.

[0075] The dispersion and coating of multi-walled carbon nanotubes is carried out on an ultrasonic disperser. On the ultrasonic disperser 1, a display screen 2, an indicator light 3, a temperature controller 4, and an ultrasonic frequency controller 5 are arranged. On the upper part of the ultrasonic disperser 1 Ultrasonic tank 6 is provided with ultrasonic water 7 in the ultrasonic tank 6, a beaker 8 in the middle of the ultrasonic tank 6, a mixed solution 9 in the beaker 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com