High-temperature resistant and low-creep polytetrafluoroethylene composite material and preparation method thereof

A polytetrafluoroethylene and composite material technology, which is applied in the field of polytetrafluoroethylene composite materials and their preparation, can solve the problems of low interface bonding strength, poor affinity, and reduce the performance of composite materials, so as to improve mechanical properties and creep resistance. The effect of denaturation, improvement of tensile strength, and improvement of interfacial bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

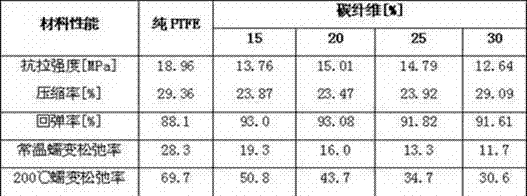

Examples

Embodiment 1

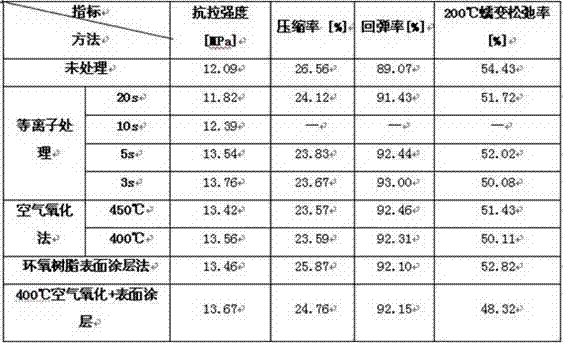

[0021] The specific operation of the carbon fiber surface coating air oxidation treatment process is: first dilute the NDZ-201 (pyrophosphate titanate) coupling agent with alcohol to prepare a solution, and the weight percentage concentration of the pyrophosphate titanate coupling agent is 10%, put in carbon fiber, stir for 30 minutes, put in a drying oven at 80°C for 4 hours, and then activate at 105±3°C for 2 hours. Oxidize the surface-coated carbon fibers at a high temperature of 400° C. for 10 minutes to obtain modified carbon fibers.

Embodiment 2

[0023] A preparation method of a polytetrafluoroethylene composite material with high temperature resistance and low creep, the method comprises the following steps:

[0024] (1) Mixing material: add the carbon fiber modified in Example 1 into a high-speed mixer, then add PTFE, the weight ratio of carbon fiber: PTFE is 1:3; stir for 10-15 min, and pass the mixed material through a 60-mesh sieve ;

[0025] (3) Compression molding: put an appropriate amount of mixture in the sealing ring mold, hold the pressure for 10 minutes on a hydraulic press at a pressure of 20-40 MPa, and release the gas twice during the boosting process to obtain a modified seal with a thickness of 2-3 mm. Non-toxic PTFE sealing ring blank;

[0026] (4) High-temperature sintering: put the billet in a special sintering furnace for PTFE materials, raise the temperature to 330 °C at a rate of 100 °C / h, and keep it for 1.5 h; then slowly heat it to 375 °C at a rate of 37 °C / h for 3 h; Then cool down from 38...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com