Production of cheese-flavor substance and application of cheese-flavor substance in food

A technology of flavoring substances and cheese, applied in the fields of microbiology and food science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

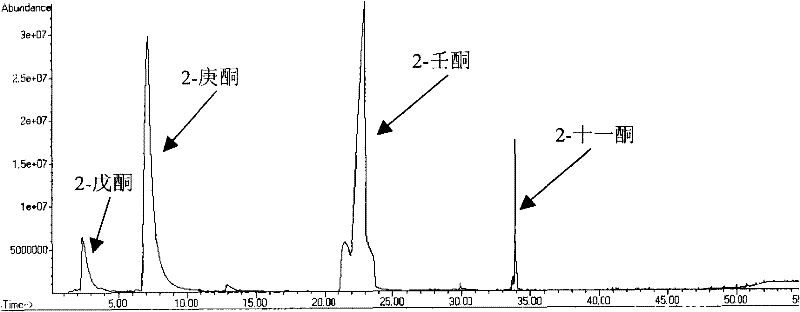

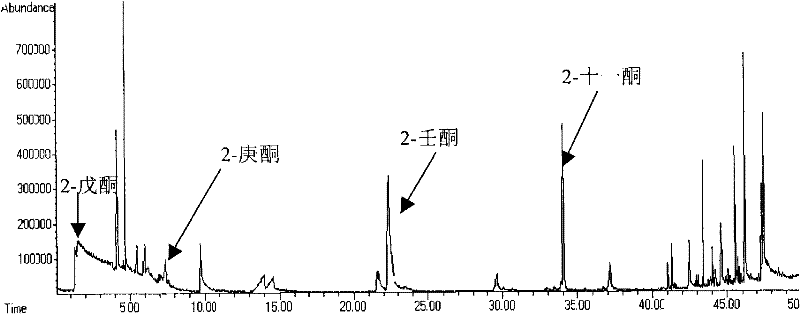

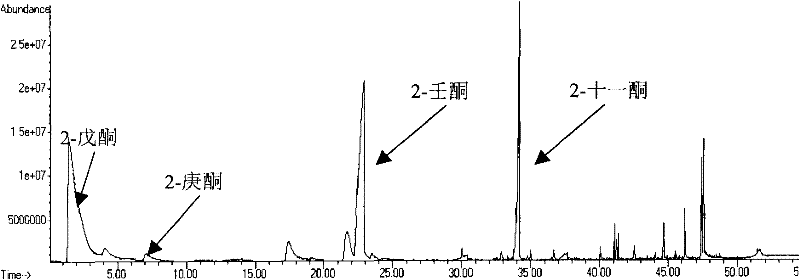

Image

Examples

Embodiment 1

[0156] Embodiment 1, production of cheese flavor substance by liquid fermentation of Eupenicillium javanicium (Eupenicillium javanicium) CFR0802 (CGMCCNo.3551)

[0157] The first step: hydrolyzing coconut oil by lipase to obtain its enzymatic hydrolysis product;

[0158] (1) Place 200g of refined coconut oil in a 500ml triangular flask, place it in a shaking water bath (40°C) and shake it in a constant temperature water bath for 30 minutes;

[0159] (2) According to the addition amount of 0.1g / 100ml, add lipase (PALATASE 20000L) for hydrolysis; during the hydrolysis process, take samples every 2 hours to measure the acid value (AV value) and free fatty acid content (FFA);

[0160] (3) When the AV value does not change significantly, the hydrolysis is terminated; then the hydrolyzate is heated to 85° C., and inactivated after 15 minutes of heat preservation; the inactivated hydrolyzate can be stored in a 4° C. refrigerator for future use.

[0161] The second step: inoculate th...

Embodiment 2

[0166] Embodiment 2, Trichoderma reesei (Trichoderma reesei) CFR0803 (CGMCC No.3553) liquid fermentation production cheese flavor substance

[0167] Gently scrape a ring of spores from the PDA slope of Trichoderma reesei CFR0803 cultivated for 3-5 days, inoculate in a 250mL Erlenmeyer flask filled with 50mL of fresh yak milk, shake back and forth (28°C, 120rpm / min) for 40 hours to obtain the primary seed liquid (ie, the primary mycelium liquid).

[0168] Draw 2.5mL of the primary seed liquid, inoculate it into a 500mL Erlenmeyer flask containing 100mL of fresh yak milk, and culture it with reciprocating vibration (28°C, 120rpm / min) for 24-26 hours to obtain the secondary seed liquid (ie, the secondary mycelium liquid ), the dry weight of mycelium is about 15-25g / L.

[0169] The obtained secondary seed liquid is inoculated into a 50L fermenter loaded with 35L fermentation substrate (which consists of fresh yak milk) in a 10% volume ratio (secondary seed liquid / fermentation su...

Embodiment 3

[0173] Example 3, Production of Cheese Flavor Substances by Liquid Fermentation of Penicillium glabrum CFR0801 (CGMCC No.3552)

[0174] Take 500g of commercially available New Zealand Anjia butter, cut the butter into 4 slices with a height of 1cm and a length and width of about 5cm with a sterile knife in a sterile room, put them in a sterile plate, and use a tool to cut the cream into 4 pieces. Pierce several small holes on the upper surface of the object (each small hole has a diameter of about 0.5-1mm);

[0175] Gently scrape the mature spores on the PDA slope of Penicillium glabrum CFR0801 cultivated for 3-5 days with an inoculation loop, pour it into a sterile salt sprinkler, vibrate evenly, and then evenly sprinkle it on the surface of Anchor Cream.

[0176] Placed in a biochemical incubator (Shanghai Jinghong Experimental Equipment Co., Ltd., SHP-250) at 25°C for 1-2 days, the upper surface of the ghee sheet is covered with white mycelium; after 10-15 days of cultivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com