Preparation method for praseodymium neodymium dysprosium alloy

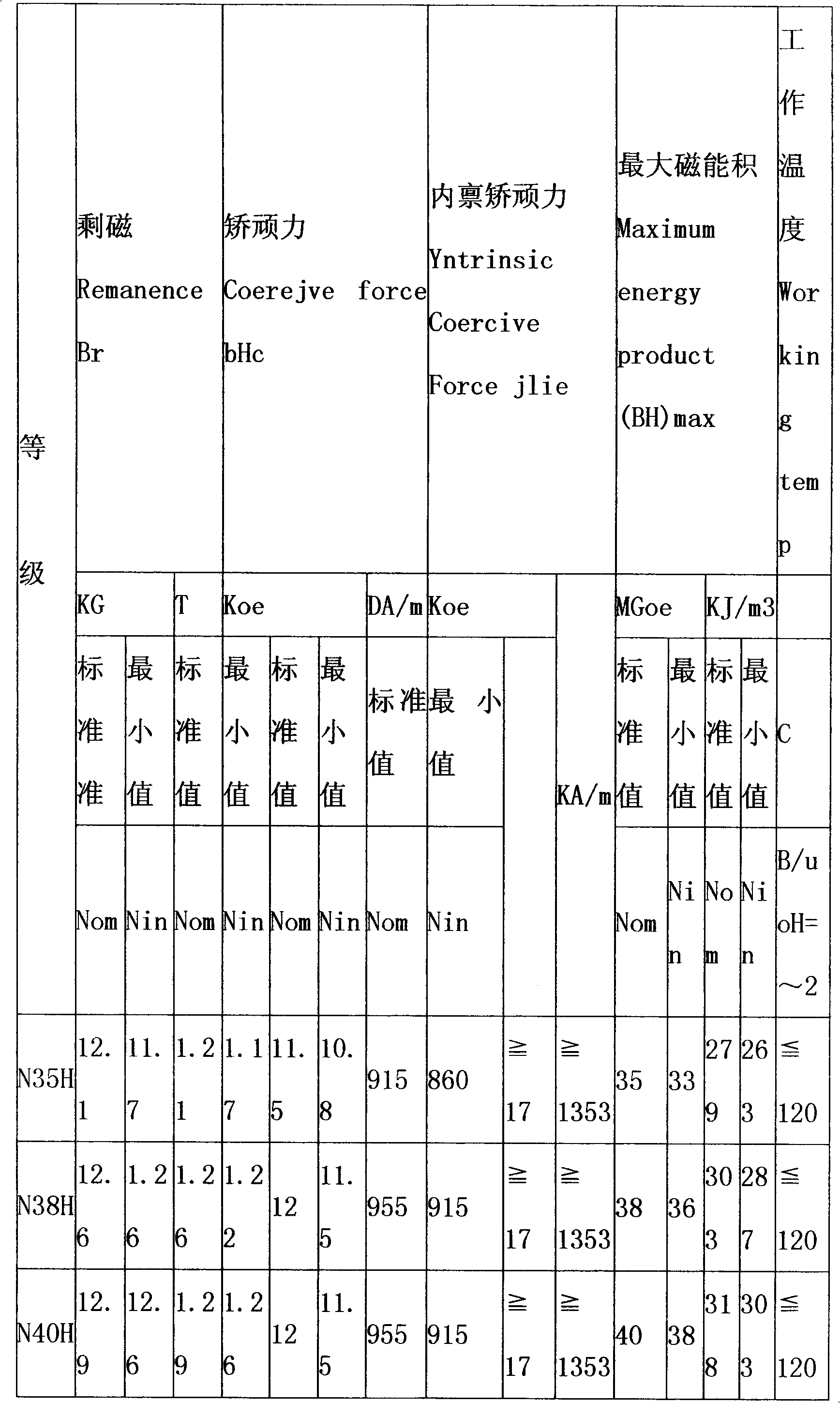

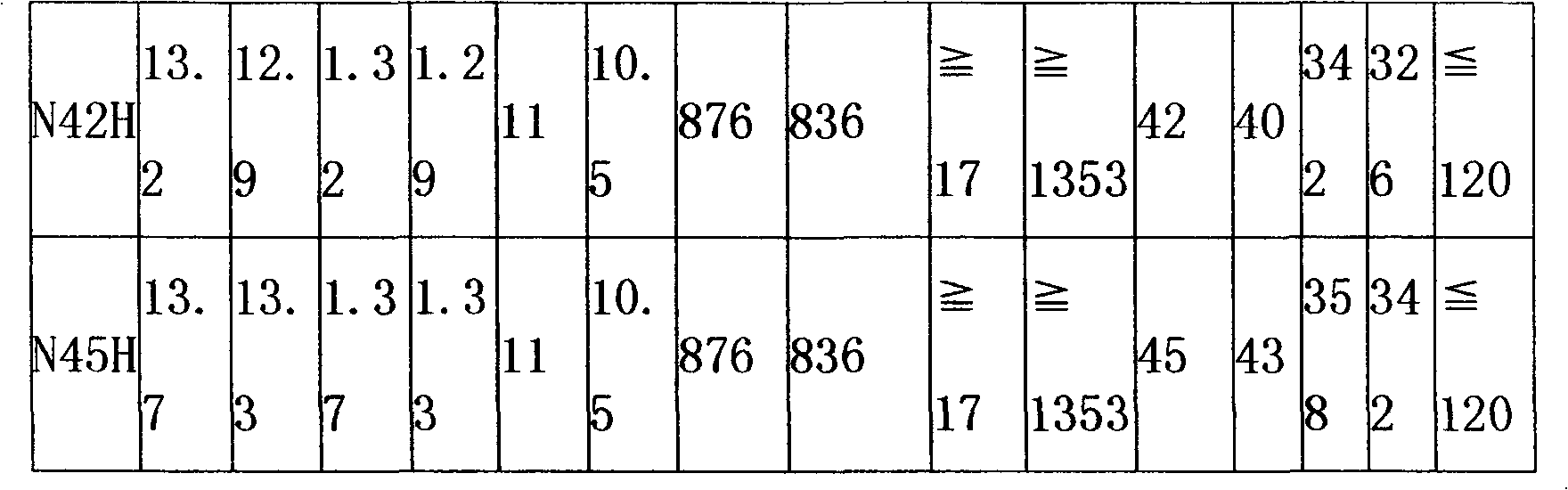

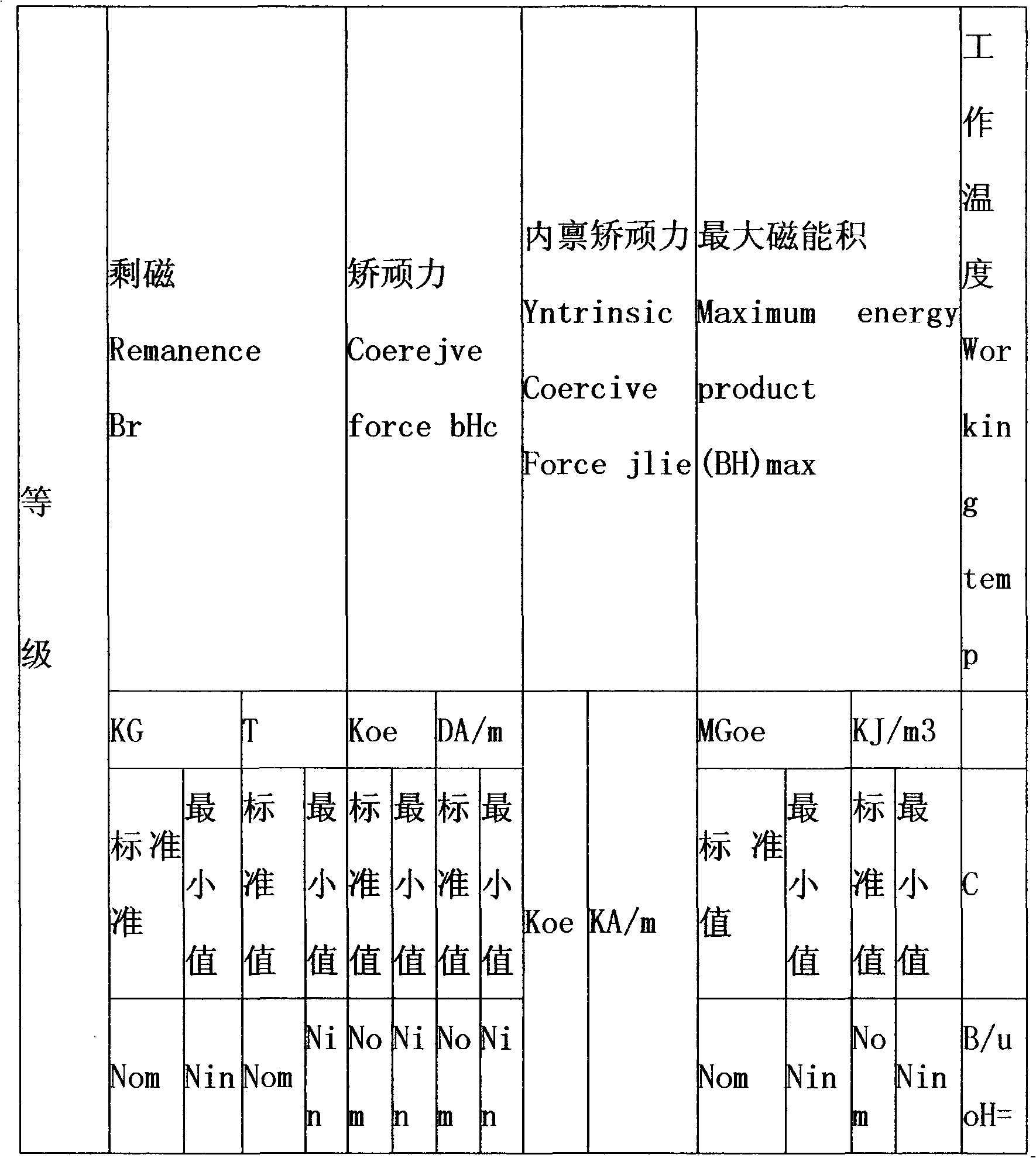

A technology of alloy, praseodymium and neodymium, which is applied in the field of preparation of neodymium and dysprosium alloy, to solve the problem of non-oxidation, improve the intrinsic coercive force, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in combination with specific embodiments.

[0023] 1) Purification and precipitation of neodymium and dysprosium:

[0024] First, the Nd-D dysprosium scrap is purified, and the purification refers to dissolving the Nd-D dysprosium scrap with hydrochloric acid with a mass concentration of 33%, and the dissolving time is 2 hours, wherein the mass ratio of the Nd-D dysprosium scrap to the hydrochloric acid is 1.1:2.5. Then the neodymium and dysprosium leftovers are precipitated, and the precipitation refers to adding 2.0 tons of oxalic acid oxalic acid per ton to the solution obtained in the above steps to precipitate the precipitate, and the water content of the precipitate is 56% after dehydration.

[0025] 2) Roasting: put the dehydrated precipitate in a roasting furnace while drying and roasting, the roasting temperature is 1050° C., and keep warm for 3 hours.

[0026] 3) After being released from the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com