Preparation method for hydrophobic dispersing material

A dispersed and hydrophobic technology, applied in the direction of heat exchange materials, chemical instruments and methods, powder coatings, etc., can solve the problems of endangering human, animal and plant health, excessive volatile organic compounds, environmental pollution, etc., to achieve convenient transportation and use, The effect of low preparation cost and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

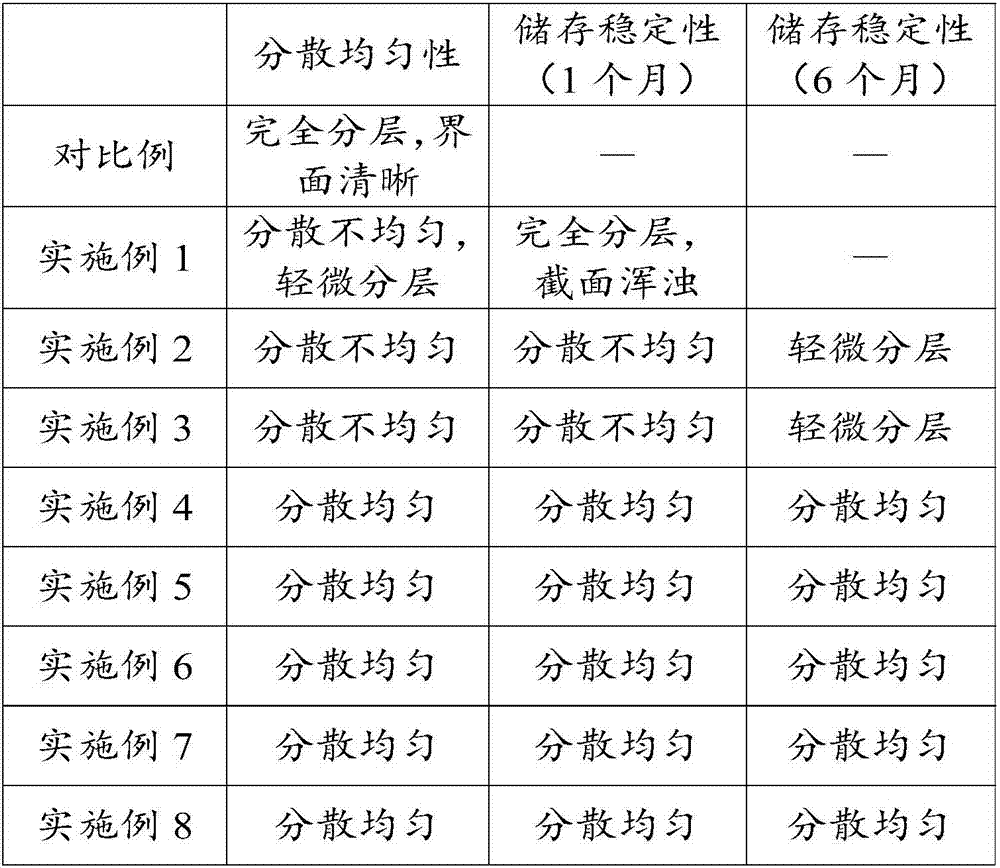

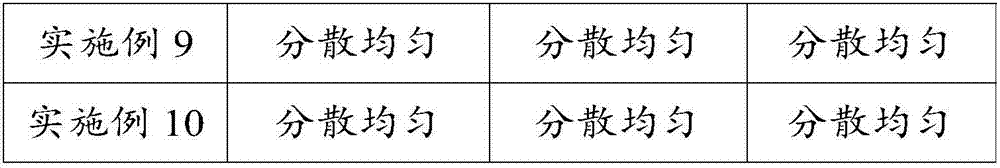

Examples

preparation example Construction

[0012] A method for preparing a hydrophobic dispersion material provided by an embodiment of the present invention includes: mixing and grinding a hydrophobic solid powder and a surfactant, and then mixing with water.

[0013] Further, in a preferred embodiment of the present invention, the mass ratio of hydrophobic solid powder, surfactant, and water is 1000:1-1000:1-100.

[0014] A method for preparing a hydrophobic dispersion material provided by an embodiment of the present invention includes:

[0015] Weigh the raw materials. In the present invention, the raw materials for preparing the hydrophobic dispersion material include water, hydrophobic solid powder, surfactant, and additives. Water is used as a solvent to replace traditional organic solvents, which is more environmentally friendly and has no harm to humans and animals.

[0016] Hydrophobic solid powder is the main raw material, has good hydrophobicity, and is widely used in the fields of thermal insulation mate...

Embodiment 1

[0030] This embodiment provides a hydrophobic solid powder dispersion material, in parts by weight, the raw materials include:

[0031] 1000 parts of water, 300 parts of hydrophobic silicon dioxide, 10 parts of dodecylphenol polyoxyethylene ether.

[0032] It is mainly prepared by the following methods:

[0033] Add the formula amount of water into the mixing tank of the high-speed liquid material mixer, add hydrophobic silicon dioxide and dodecylphenol polyoxyethylene ether into the water, disperse evenly, and stir for 20 minutes.

[0034] After metering and packaging, a hydrophobic solid powder dispersion material is obtained.

Embodiment 2

[0036] This embodiment provides a hydrophobic solid powder dispersion material, in parts by weight, the raw materials include:

[0037] 1000 parts of water, 400 parts of hydrophobic silica, 100 parts of hydrophobic silica airgel, 20 parts of cetyl ammonium phosphate, 1.79 parts of boric acid, 1.21 parts of borax, 4 parts of cellulose, 1 part of bentonite, calcium propionate 1 part, 1 part propylparaben.

[0038] It is mainly prepared by the following methods:

[0039] Add the formulated amount of water, hydrophobic silica, hydrophobic silica aerogel, cetyl ammonium phosphate, boric acid, borax, bentonite, cellulose, calcium propionate and p-hydroxy Propyl benzoate, dispersed evenly, stirred for 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com