High-precision jacquard glass fiber fabric

A technology of glass fiber cloth and glass fiber, which is applied in the field of printed circuit board manufacturing. It can solve the problems of uneven surface and easy warping of the glass fiber cloth base material, and achieve high working temperature, low dielectric constant, and high frequency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

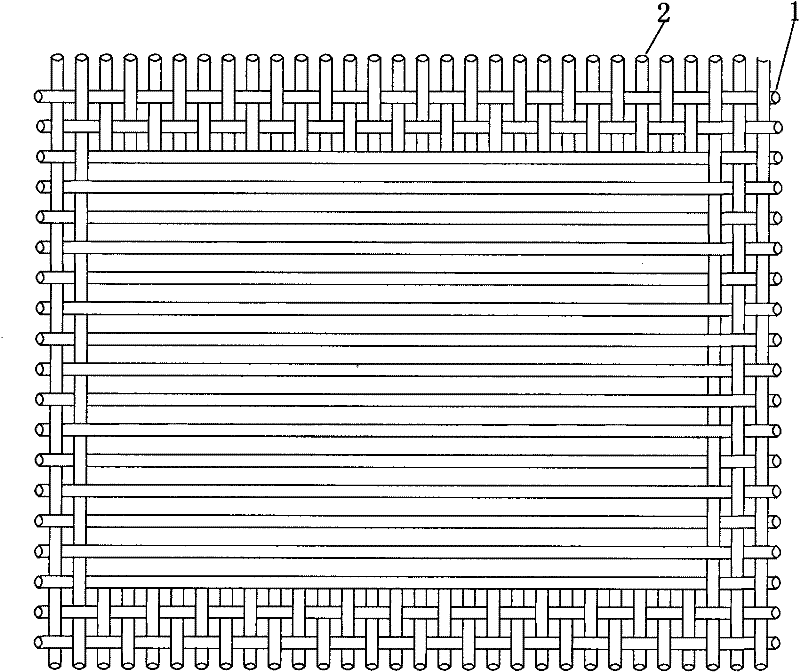

[0016] Jacquard weaving: select glass fibers with a diameter of 0.009-0.05mm, and weave them into such figure 1 In the circuit area shown, since the width of the jacquard machine is usually about 190 to 350 cm, multiple pieces such as figure 1 The same circuit area shown to meet the demands of modern mass production, figure 1 The central circuit area is the area that is preset to form a circuit. In this embodiment, only warp 1 can be seen on the front of the fabric, that is, only warp 1 or weft 2 is on the side carrying electronic components when the printed circuit board is finally formed. The rest of the area other than the central area is the surrounding transition area, where the warp 1 and weft 2 are normally interwoven to form a plain weave, thereby forming a firm weave structure.

[0017] Pre-cutting: Cut according to the jacquard shape forming the central circuit area, and retain some surrounding transition areas to ensure that the cut glass fiber cloth can maintain t...

Embodiment 2

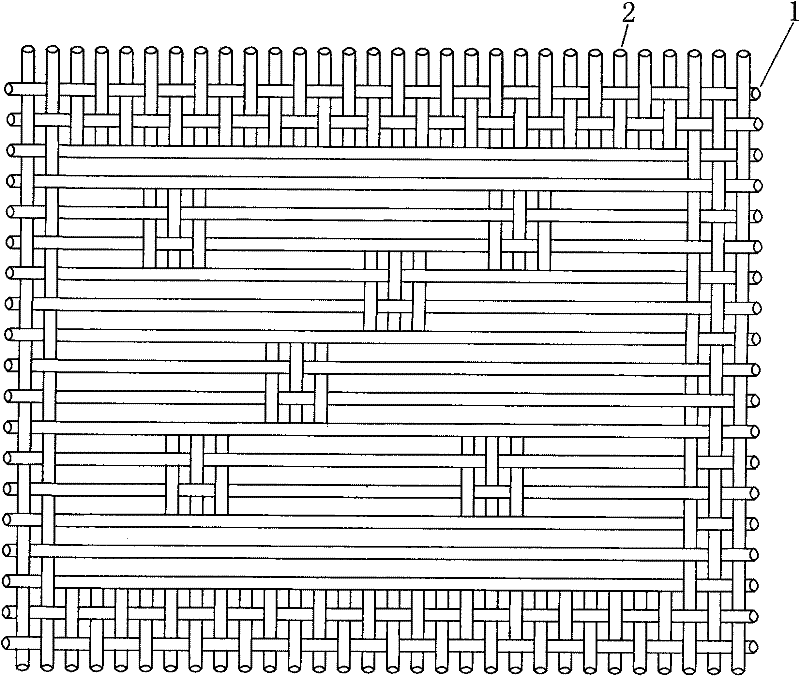

[0024] Compared with Example 1, the difference is that the central circuit area has several interweaving areas of warp yarn 1 and weft yarn 2 when the jacquard machine is weaving. This interweaving area can be designed according to the needs of circuit wiring, which not only can ensure The structure of the circuit area is stable, and it can also be used for drilling holes in the final circuit board.

[0025] Other steps are with embodiment 1.

[0026] In addition, this embodiment 2 only shows the case where the central region has several dot-shaped interleaving regions. In fact, continuous interweaving regions can be designed according to the needs of circuit wiring, so that the shape of the non-interleaving region is consistent with the final circuit shape to be formed. Correspondingly, by designing high-precision glass fiber cloth in this way, even if the glass fiber shrinks or stretches during processing, the amount of shrinkage or stretching is basically the same in the en...

Embodiment 3

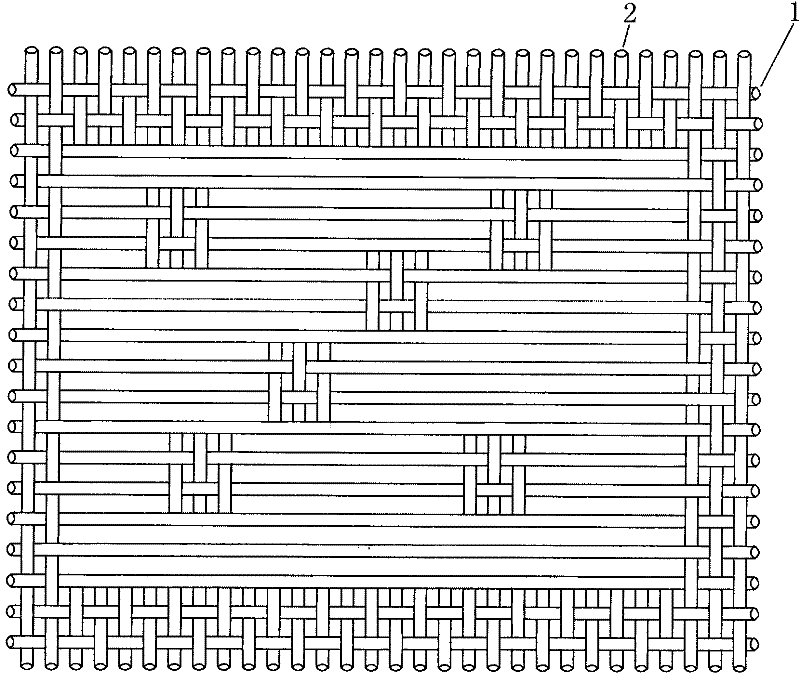

[0028] Compared with Examples 1 and 2, the difference is that the surface of the Jacquard woven base fabric has multiple different circuit areas, that is, different circuit shapes can be designed on the continuously woven glass fiber cloth according to the different quantities required by customers.

[0029] Other steps are with embodiment 1 and 2.

[0030] By arranging different circuit areas in the width direction, some requirements for permitting small batches can be met, and at the same time, the overall weaving cost can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com