Dispersing device for micron/nano-particle suspension

A nanoparticle and dispersing device technology, which is applied in the direction of shaking/oscillating/vibrating mixers, dissolving, mixing machines, etc., can solve the problems of low dispersion efficiency, high energy consumption, high surface energy, etc., to avoid noise pollution and improve heat transfer efficiency High, large total surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

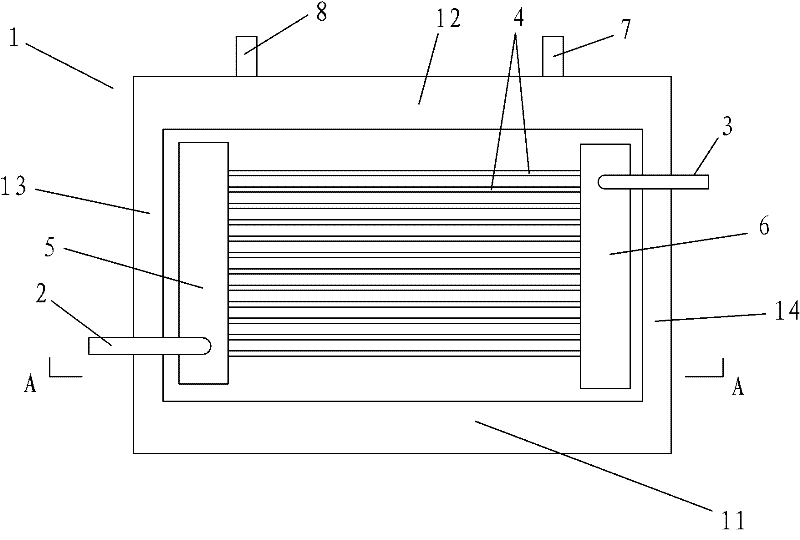

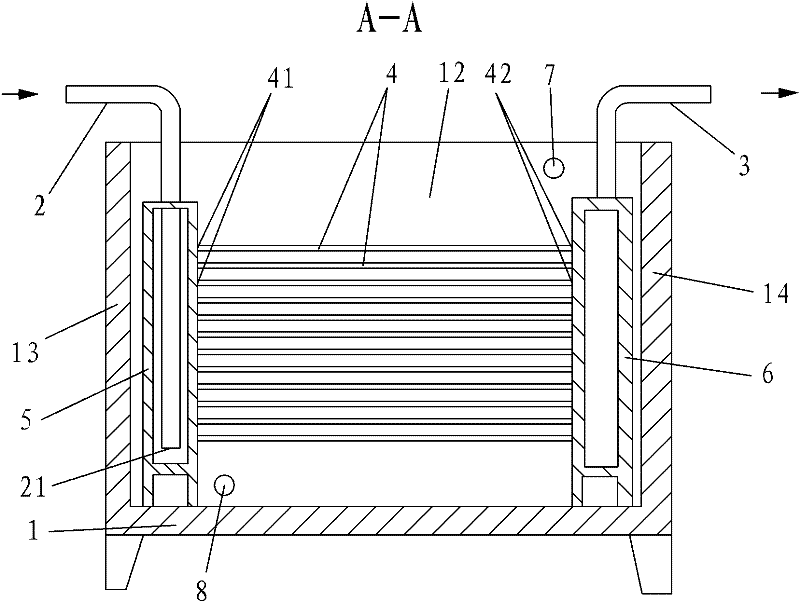

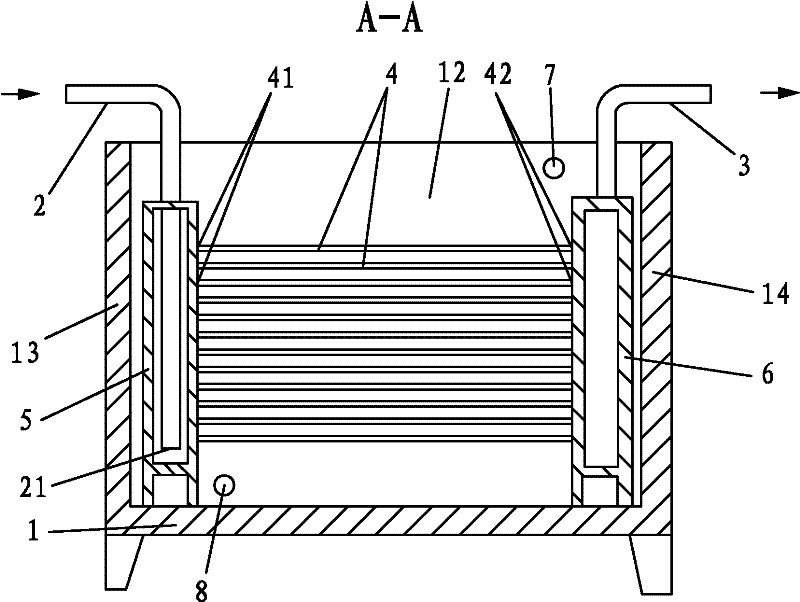

[0033] The dispersion device of a kind of micro / nano particle suspension of the present invention, as Figure 1-Figure 2 As shown, it includes an ultrasonic tank 1, a liquid inlet pipe 2, a liquid outlet pipe 3 and several branch liquid pipes 4, wherein:

[0034] Ultrasonic tank 1 is a cuboid structure with an upper end opening, and the inner tank material is made of 3 mm thick stainless steel plate No. 304. The two side walls along the length direction of ultrasonic tank 1 are called front side wall 11 and rear side wall 12. In addition, the two side walls are called left side wall 13 and right side wall 14; The ultrasonic transducer (not shown in the figure) connected by wires, that is, the working mode adopts the double-sided side vibration mode. In the specific operation, the ultrasonic frequency can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com