Modified aluminium trippolyhosphate anticorrosive paint with high efficiency

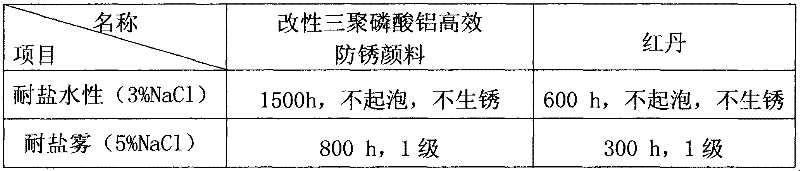

A technology of aluminum tripolyphosphate and anti-rust pigments, which is applied in the direction of anti-corrosion coatings, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of inability to use anti-rust pigments, damage the storage stability of coatings, etc., and achieve the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 50.0kg of deionized water into the kettle, and add 58.0kg of aluminum tripolyphosphate under high-speed stirring (1200rpm / min), so that the aluminum tripolyphosphate is evenly dispersed in the water.

[0022] (2) Raise the temperature to 50-60°C, add 0.4 kg of ammonium molybdate and 0.8 kg of zinc molybdate under high-speed stirring, and disperse for 35 minutes.

[0023] (3) Keeping the temperature constant, add 36.4 kg of calcium metasilicate in sequence under high-speed stirring, and disperse and react for 20 minutes.

[0024] (4) Keep the temperature constant, add 3.8 kg of calcium oxide under high-speed stirring, and adjust the pH value to 6.5.

[0025] (5) Raise the temperature to 80-90°C, add 0.6 kg of γ-aminopropyltriethoxysilane, and stop the reaction after 50 minutes.

[0026] (6) Filter, dry, pulverize and sieve the modified material to obtain the finished product.

Embodiment 2

[0028] (1) Add 55.0kg of deionized water to the kettle, and add 60.0kg of aluminum tripolyphosphate under high-speed stirring (1400r / min), so that the aluminum tripolyphosphate is evenly dispersed in the water.

[0029] (2) Raise the temperature to 50-60°C, add 2.2 kg of zinc molybdate and 0.8 kg of calcium molybdate under high-speed stirring, and disperse for 40 minutes.

[0030] (3) Keeping the temperature constant, add 20.0 kg of calcium metasilicate, 6.4 kg of barium sulfate, and 5.0 kg of calcium carbonate in sequence under high-speed stirring, and disperse for 30 minutes.

[0031] (4) Keep the temperature constant, add 3.0 kg of zinc oxide and 1.8 kg of calcium hydroxide under high-speed stirring, and adjust the pH value to 6.2.

[0032] (5) Raise the temperature to 80-90° C., add 0.8 kg of bis(dioctyloxypyrophosphate) ethylene titanate, and stop the reaction after 50 minutes.

[0033] (6) Filter, dry, pulverize and sieve the modified material to obtain the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com