Nano barium sulfate/cellulose composite membrane as well as preparation method and application thereof

A nano-barium sulfate and cellulose technology is applied in the field of nano-barium sulfate/cellulose composite membrane and its preparation, which can solve the problem that the particle size of nano-barium sulfate is not very uniform, and achieve long-lasting anti-radiation stability and porosity. Large, easy functional expansion and the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

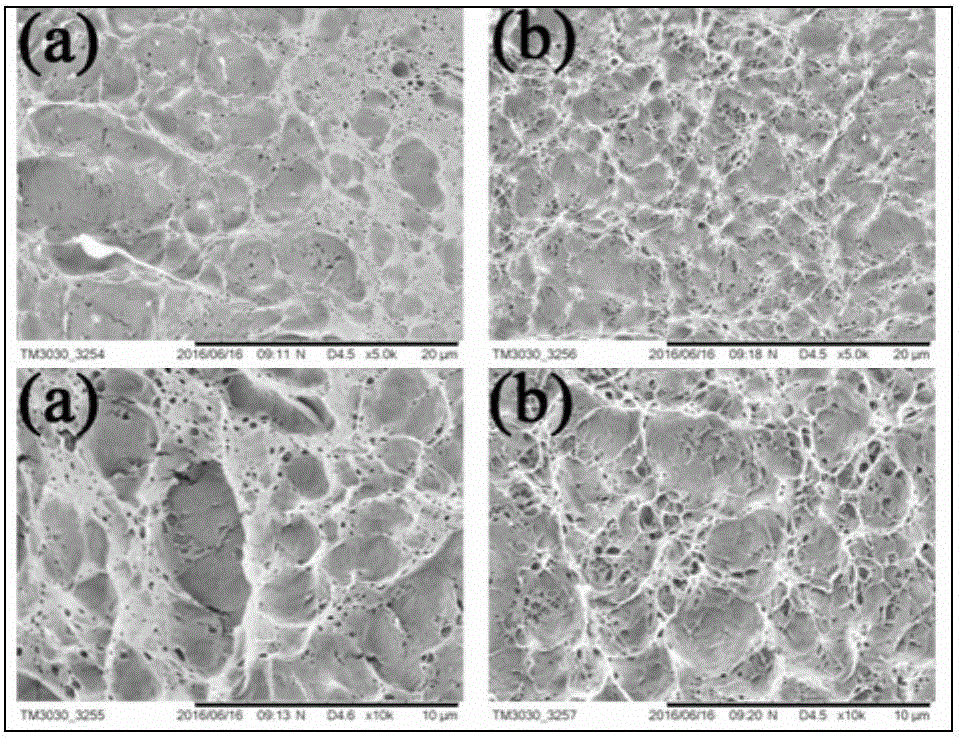

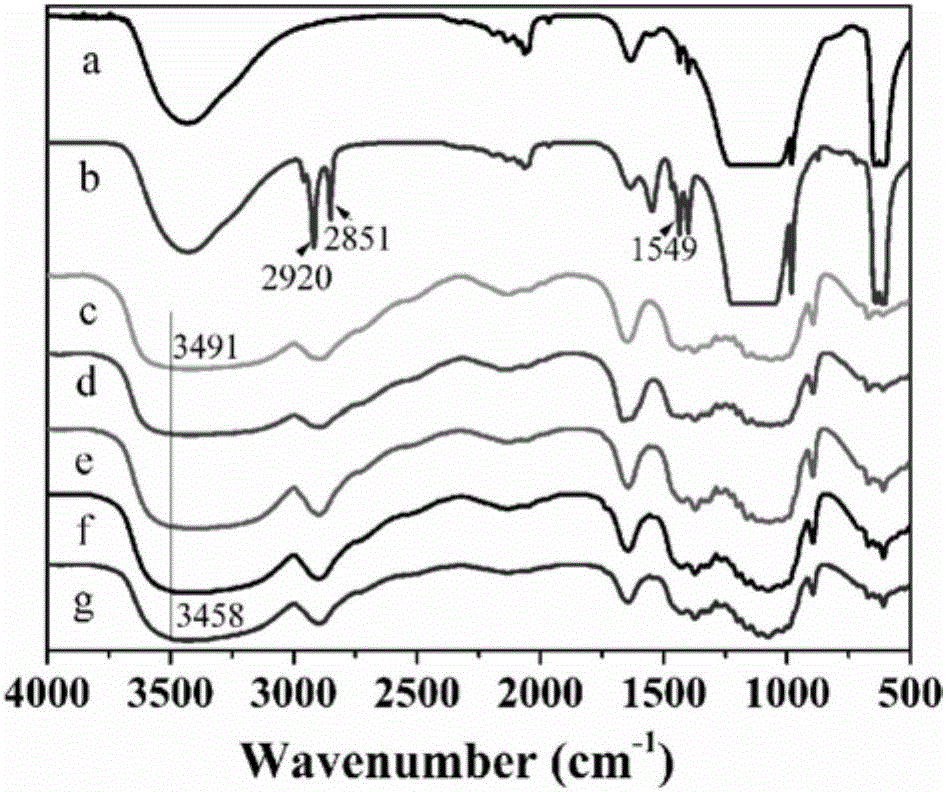

[0031] The preparation of nano barium sulfate / cellulose composite film, concrete steps are as follows:

[0032] 1) Solution preparation: 1.4204g of Na 2 SO 4 and 2.4426 g of BaCl 2 2H 2 O was dissolved in 100ml of ethanol-water solution with a volume fraction of 50%, respectively, to obtain Na with a concentration of 0.1mol / L 2 SO 4 Ethanol-water solution and a concentration of 0.1mol / L BaCl 2 ethanol-water solution;

[0033] 2) to Na 2 SO 4 Ethanol-water and BaCl 2 Ethanol-water solution for optimization: in Na 2 SO 4 Add NH dropwise to ethanol-water solution 3 ·H 2 O until the pH of the solution was 9; in BaCl 2 0.017 g of stearic acid was added to the ethanol-water solution.

[0034] 3) Preparation of nano barium sulfate particles: 100mL Na 2 SO 4 Ethanol-water solution was added dropwise to 100mL BaCl at a rate of 60mL / h 2 ethanol-water solution, and continuously carry out magnetic stirring. After the reaction, continue stirring at constant temperature for...

Embodiment 2

[0041] The preparation of nano barium sulfate / cellulose composite film, concrete steps are as follows:

[0042] 1) Solution preparation: 7.102g of Na 2 SO 4 and 12.213 g of BaCl 2 2H 2 O was dissolved in 100ml of ethanol-water solution with a volume fraction of 50%, respectively, to obtain Na with a concentration of 0.5mol / L 2 SO 4 Ethanol-water solution and a concentration of 0.5mol / L BaCl 2 Ethanol-water solution.

[0043] 2) Preparation of nano-barium sulfate particles: same as step 3) in Example 1.

[0044] 3) Preparation of modified nano-barium sulfate / cellulose solution: same as step 4) in Example 1.

[0045] 4) Preparation of nano-barium sulfate / cellulose composite film: same as step 5) in Example 1.

[0046] After testing, in the obtained nano-barium sulfate / cellulose composite film, the average diameter of nano-barium sulfate particles is 280nm.

Embodiment 3

[0048] The preparation of nano barium sulfate / cellulose composite film, concrete steps are as follows:

[0049] 1) Solution preparation: 7.102g of Na 2 SO 4 and 12.213 g of BaCl 2 2H 2 O was dissolved in 50ml of ethanol-water solution with a volume fraction of 50%, respectively, to obtain Na with a concentration of 1mol / L 2 SO 4 Ethanol-water solution and a concentration of 1mol / L BaCl 2 Ethanol-water solution.

[0050] 2) to Na 2 SO 4 Ethanol-water and BaCl 2 Ethanol-water solution for optimization: in Na 2 SO 4 Add NH dropwise to ethanol-water solution 3 ·H 2 O until the pH of the solution was 9; in BaCl 2 0.017 g of stearic acid was added to the ethanol-water solution.

[0051] 3) Preparation of nano-barium sulfate particles: same as step 3) in Example 1.

[0052] 4) Preparation of modified nano-barium sulfate / cellulose solution: same as step 4) in Example 1.

[0053] 5) Preparation of nano-barium sulfate / cellulose composite film: same as step 5) in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com