Oily-to-aqueous epoxy anti-rust prime coat and preparation method thereof

A technology of anti-rust primer and water-based epoxy resin, applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of difficult promotion and application, low hardness of paint film, short development history, etc., and achieve good adhesion Focus on, broad application prospects, strong anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

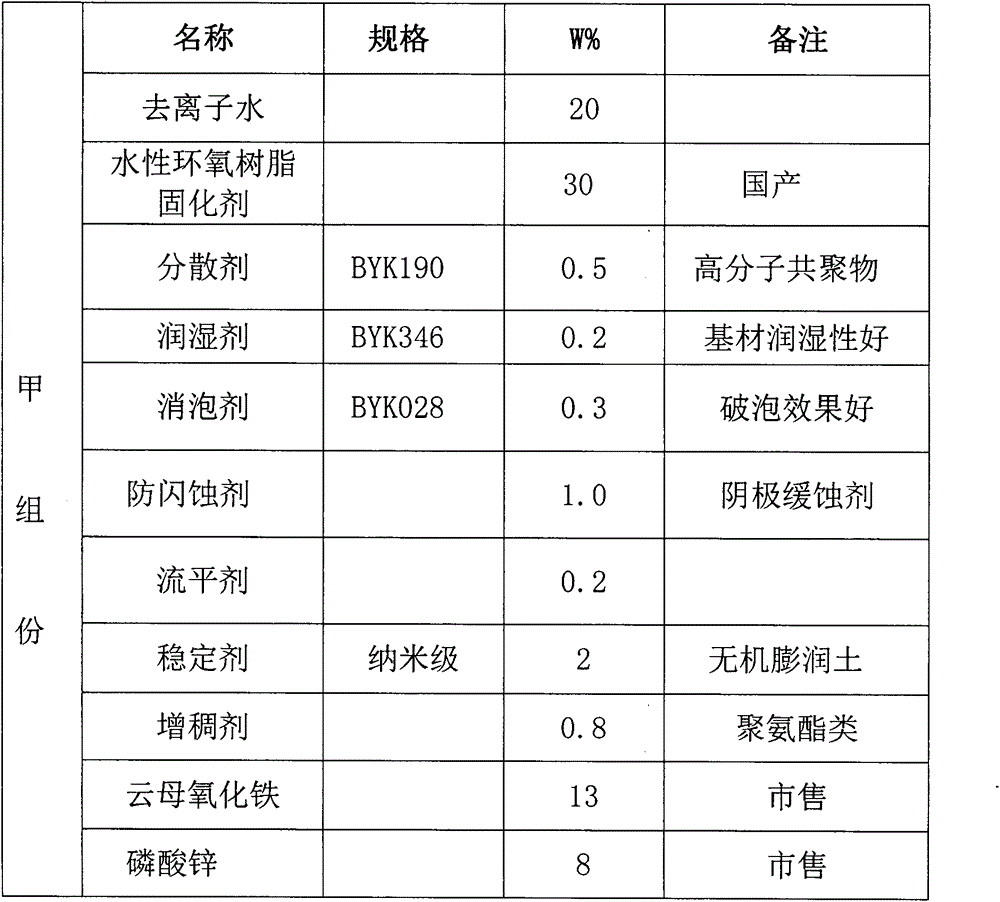

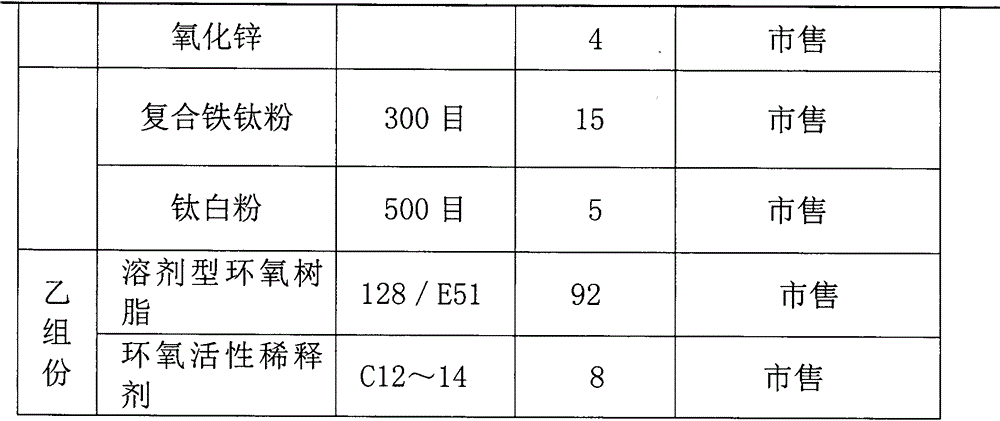

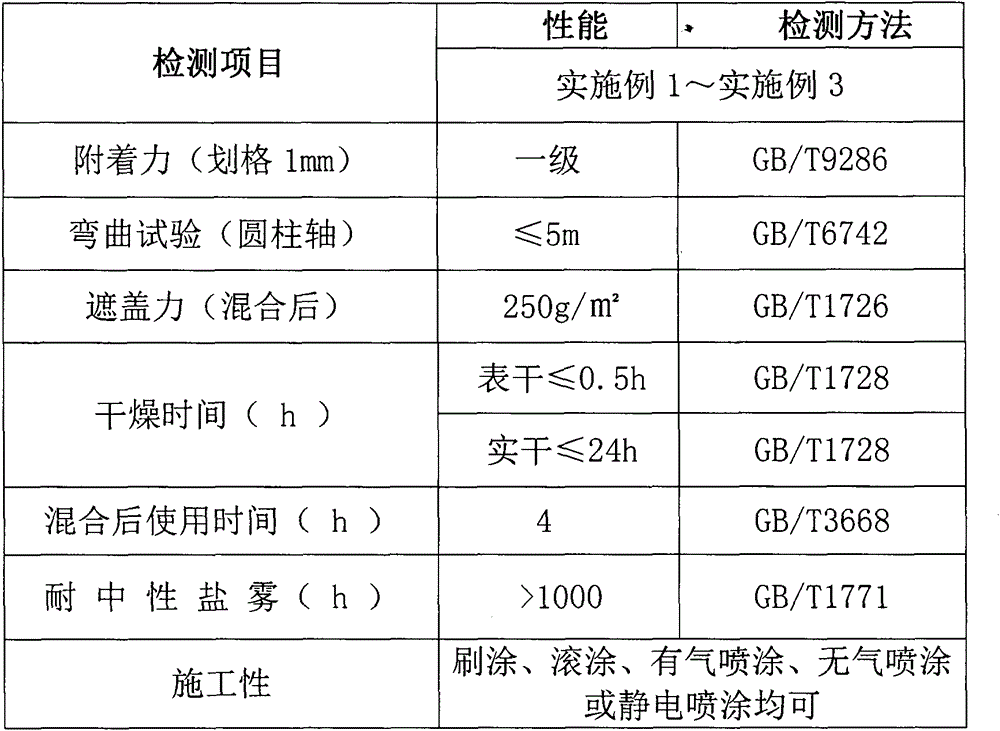

[0023] An oil-based water-based epoxy antirust primer, consisting of component A and component B, the mass ratio of component A to component B is 5:1; by mass fraction, wherein: Components include: 30% water-based epoxy resin curing agent, 5% additives, 45% anti-rust pigment and 20% deionized water; component B includes: 92% solvent-based epoxy resin and 8% epoxy reactive diluent.

[0024] The composition of the auxiliary agent is a dispersant, a wetting agent, a defoamer, an anti-flash corrosion agent, a leveling agent, a stabilizer and a thickener, and the mass ratios of various components in the auxiliary agent to the first component are respectively 0.5 %, 0.2%, 0.3%, 1.0%, 0.2%, 2%, 0.8%.

[0025] The water-based epoxy resin curing agent is a water-dilutable amine curing agent without surfactant, and the amine value of the water-based epoxy resin curing agent is 160.

[0026] The anti-rust pigment is a combination of mica iron oxide, zinc phosphate, zinc oxide, composit...

Embodiment 2

[0038] An oil-based water-based epoxy antirust primer, consisting of component A and component B, the mass ratio of component A to component B is 7:1; by mass fraction, wherein: Components include: 35% water-based epoxy resin curing agent, 4% additives, 40% anti-rust pigments and 21% deionized water; component B includes: 90% solvent-based epoxy resin and 10% epoxy reactive diluent.

[0039] The composition of the above-mentioned auxiliary agent is dispersant, wetting agent, defoamer, anti-flash corrosion agent, leveling agent, stabilizer and thickener, and the mass ratio of each composition in the auxiliary agent to the first component is 0.5% respectively , 0.2%, 0.3%, 1.0%, 0.2%, 1%, 0.8%.

[0040] The water-based epoxy resin curing agent is a water-dilutable amine curing agent without surfactant, and the amine value of the water-based epoxy resin curing agent is 220.

[0041] The anti-rust pigment is a composition of mica iron oxide, zinc phosphate, zinc oxide, composite i...

Embodiment 3

[0049] An oil-based water-based epoxy antirust primer, consisting of a component and a component B, the mass ratio of the component A to the component B is 6:1; by mass fraction, wherein: Components include: 30% water-based epoxy resin curing agent, 6% additives, 42% anti-rust pigment and 22% deionized water; component B includes: 91% solvent-based epoxy resin and 9% epoxy reactive diluent.

[0050] The above additives are composed of dispersant, wetting agent, defoamer, anti-flash corrosion agent, leveling agent, stabilizer and thickener, and the mass ratio of various components in the additive to the component A is 0.5% respectively , 0.2%, 0.3%, 1.5%, 0.5%, 2%, 1%.

[0051] The water-based epoxy resin curing agent is a water-dilutable amine curing agent without surfactant, and the amine value of the water-based epoxy resin curing agent is 190.

[0052] The anti-rust pigment is a combination of mica iron oxide, zinc phosphate, zinc oxide, composite iron-titanium powder and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com