Rotary kiln automatic control system and method

An automatic control system and rotary kiln technology, which is applied in the field of metal smelting, can solve the problems of unstable calcination temperature, inability to monitor the operating parameters of the rotary kiln in time, and unstable quality of reduced raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

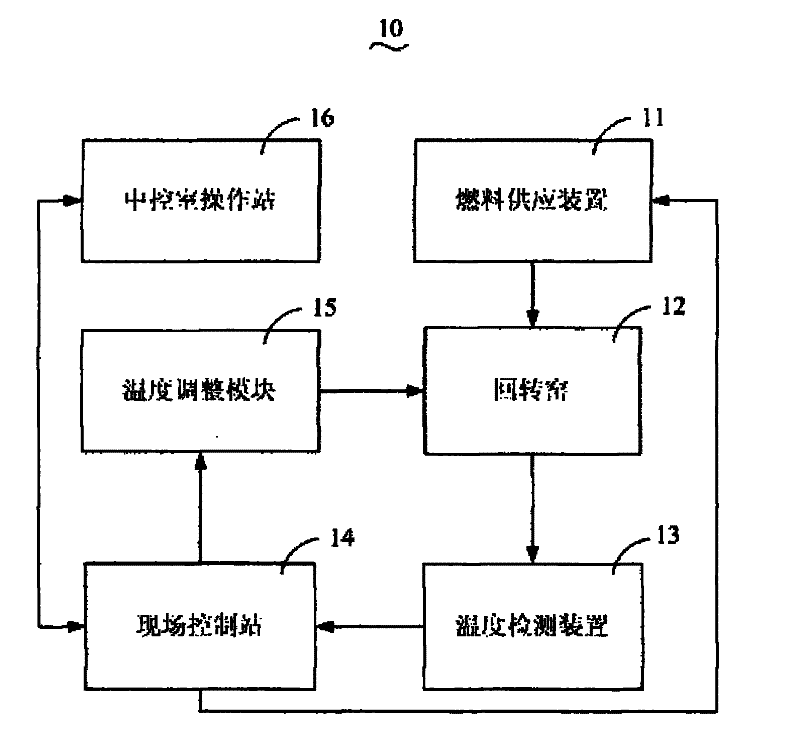

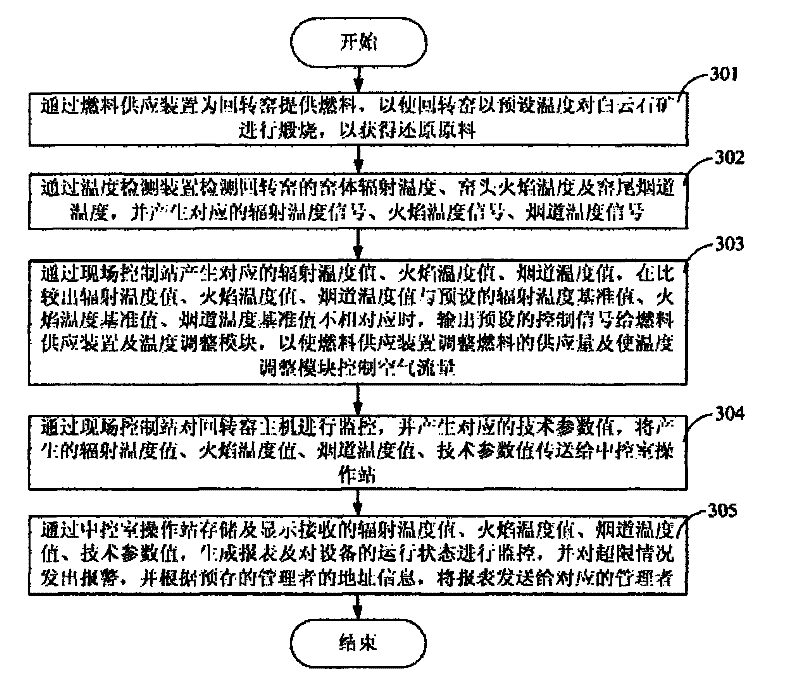

[0017] Such as figure 1 The rotary kiln automatic control system 10 shown includes a fuel supply device 11 , a rotary kiln 12 , a temperature detection device 113 , an on-site control station 14 , a temperature adjustment module 15 and a central control room operation station 16 .

[0018] The fuel supply device 11 is used to provide fuel for the rotary kiln 12, and adjust the supply amount of fuel according to the control signal provided by the field control station 14. Among them, the amount of fuel provided by the fuel supply device 11 to the rotary kiln 12 and the adjustment of the fuel supply amount according to the control signal provided by the field control station 14 are determined according to actual production needs, so as to provide a certain amount of calcined fuel for the calcination of the rotary kiln to ensure the rotary kiln. The stability of the calcination temperature in the kiln.

[0019] The rotary kiln 12 is used to use the fuel provided by the fuel devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com