Simulation testing machine for evaluating cooling uniformity of internal combustion engine

A simulation test and uniform cooling technology, which is applied in the field of simulation test machines, can solve the problems of inability to realize quantitative measurement of coolant flow uniformity, inability to arrange temperature and pressure sensors in the water jacket, and high test cost, so as to shorten the test cycle and test cycle The effect of long time and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

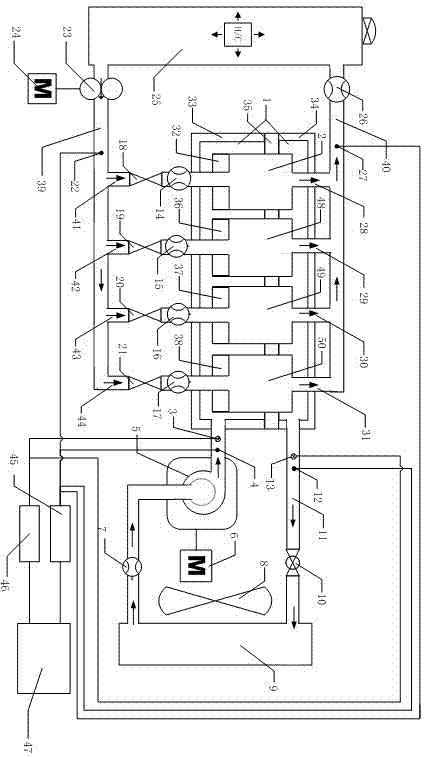

[0019] Such as figure 1 As shown, the simulation test machine for evaluating the cooling uniformity of an internal combustion engine includes an internal combustion engine cooling water jacket 1, a first cylinder 2 of an internal combustion engine, a cooling water inlet pressure sensor 3, a cooling water inlet temperature sensor 4, a water pump 5, a first motor 6, a cooling water Flowmeter 7, cooling fan 8, radiator 9, first throttle valve 10, water pipe 11, cooling water outlet temperature sensor 12, cooling water outlet pressure sensor 13, first cylinder flowmeter 14, second cylinder flowmeter 15, The third cylinder flow meter 16, the fourth cylinder flow meter 17, the first cylinder throttle valve 18, the second cylinder throttle valve 19, the third cylinder throttle valve 20, the fourth cylinder throttle valve 21, the heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com