Indoor 3D (3-dimensional) dimension measurement method

A technology of three-dimensional dimensions and measurement methods, applied in the direction of measuring devices, instruments, optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

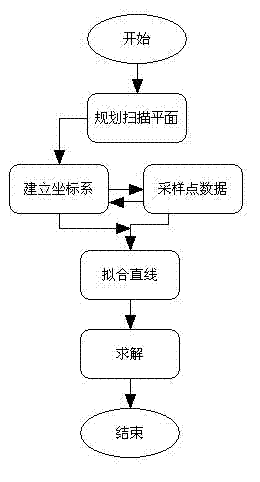

[0041] Embodiment one: see figure 1 , the indoor three-dimensional dimension measuring method is characterized in that the operation steps are:

[0042] 1) Plan the scanning plane: plan the scanning plane required by the indoor three-dimensional size according to the requirements;

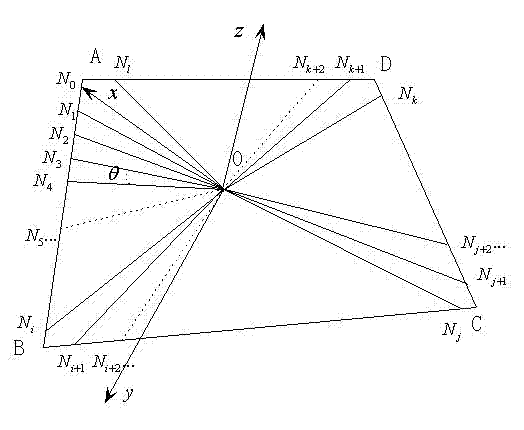

[0043] 2) Establish a coordinate system: construct a coordinate system according to the first point vector and the rotation direction vector of the scanning plane;

[0044] 3) Sampling: Obtain the angle and distance values according to the scanning plan, and obtain the coordinates of the sampling points after converting to the construction coordinate system;

[0045] 4) Fitting: Carry out real-time straight line fitting on the sampling points based on the least square method, use the fitted straight line to judge the real-time wall quality, and at the same time obtain multiple fitting straight line equations of the sides of the plane;

[0046] 5) Solving: Based on the fitted multiple straight...

Embodiment 2

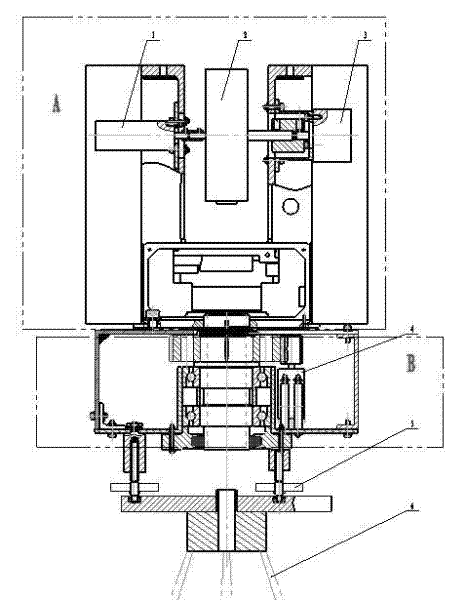

[0047] Embodiment two: This embodiment is basically the same as Embodiment 1, and the specific operation of each step is as follows: first in combination with the attached figure 2 The basic structure of the scanning device shown in this example is described below. The part that controls movement is basically divided into two parts, A and B, as shown in the accompanying drawings. Part B drives part A to rotate horizontally. In part A, 1 is a DC motor, 2 is a laser sensor, and 3 is a photoelectric encoder, which can obtain the angle of rotation. 1 DC motor can drive 2 laser sensors to move vertically, and the photoelectric encoder can record the relative angle of movement. 4 is a stepper motor to control part A to move at a certain angle, 5 is the leveling structure of the whole device, and 6 is a height-adjustable support structure, generally a tripod.

[0048] first as attached figure 1 Shown is the flow chart of the work implementation, where the planned scanning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com