Light engine system for reflective liquid crystal projection display

A liquid crystal projection and reflection technology, applied in the field of light engine system, can solve the problem of not improving the efficiency of the whole machine, and achieve the effect of increasing the complexity of the system, improving the optical efficiency and the overall brightness, and maximizing the utilization rate of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

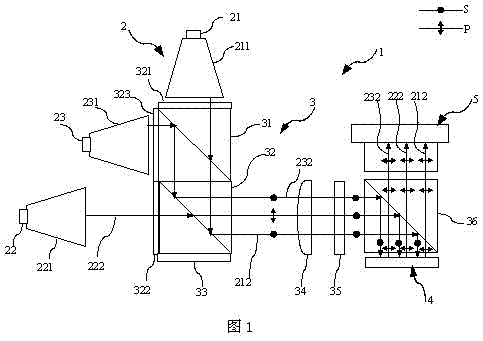

[0035] figure 1 The first embodiment of the present invention for the reflective liquid crystal projection display system 1 is given, which includes a light source module 2, a polarization management module 3, an image information module 4 and a projection lens 5.

[0036] The light source module 2 includes a red light LED 21, a green light LED 22, a blue LED 23, a red light homogenizing device 211, a green light homogenizing device 221, and a blue light homogenizing device 231. The red LED 21 and the red light homogenizing device 211 are connected, The green LED 22 is connected to the green light homogenizing device 221, and the blue LED 23 is connected to the blue light homogenizing device 231.

[0037] The natural light of the three primary colors emitted by the red light LED 21, the green light LED 22, and the blue light LED 23 is collected into a small-angle rectangular beam required for illumination after passing through a red light homogenizing device 211, a green light homog...

Embodiment 2

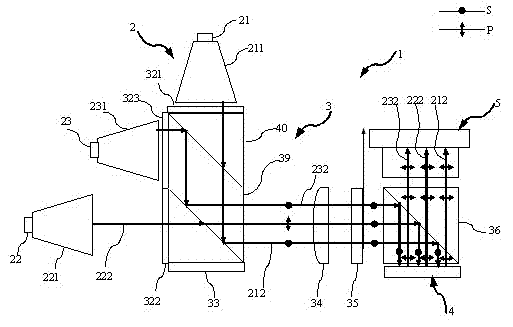

[0050] image 3 A second example of the present invention is given. Compared with the first example, in the polarization color combination unit of the second example, a parallelogram prism 39 is used to glue two first right-angle prisms 40 instead of the dichroic prism 31 and the first PBS, and the parallelogram prism One color combination surface of 39 is coated with a dichroic film and then a first right-angle prism 40 is glued, and the other color surface of the parallelogram prism 39 is coated with a polarization beam splitting film and then a first right-angle prism 40 is glued. The advantage is that the interface between the dichroic prism 31 and the first PBS 32 is reduced, which is more conducive to the integration of the optical system.

Embodiment 3

[0052] Figure 4 A third example of the present invention is given. This instance is different from figure 1 The example is that in the polarization combining unit, the red quarter-wave plate 321 and the blue quarter-wave plate 323 are replaced with a wide-band quarter-wave plate 324 and glued to the dichroic prism 31 and the first PBS, reduce the number of quarter wave plates. in figure 1 In the example, the design wavelength of each quarter wave plate adopts the center wavelength of the corresponding light source. Since the spectrum of each primary color itself is very narrow, ordinary quarter-wave plates can achieve high polarization conversion for monochromatic light, such as Picture 11 (A). In this example, if a traditional quarter-wave plate is used, since the center wavelengths of red light and blue light are far apart, the polarization conversion efficiency of light outside the design wavelength will rapidly decrease as the wavelength deviates. Therefore, in this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com