Ultraviolet light curing equipment and method for alarming the ultraviolet light curing equipment

A technology of ultraviolet light and equipment, which is applied in microlithography exposure equipment, alarms, exposure devices for photolithography, etc., can solve the problem of high scrap rate of substrates, achieve high alarm accuracy, avoid production losses, and eliminate faults in a timely manner. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

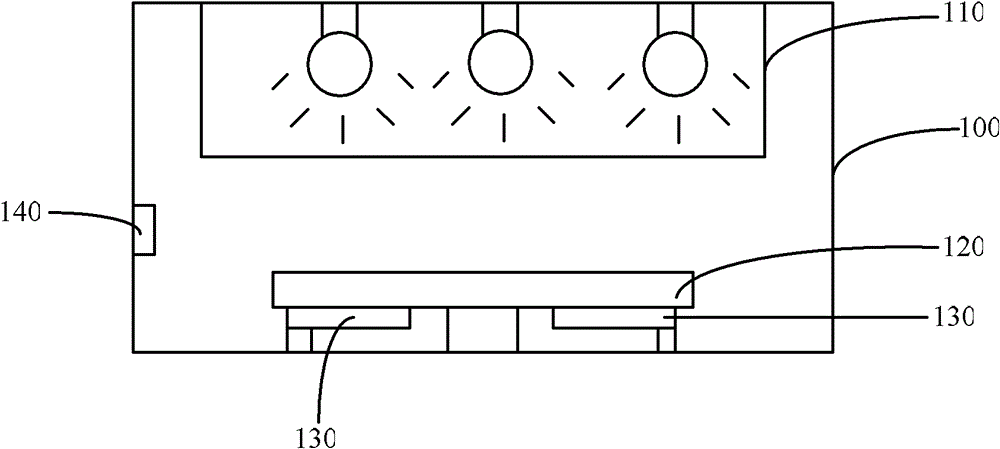

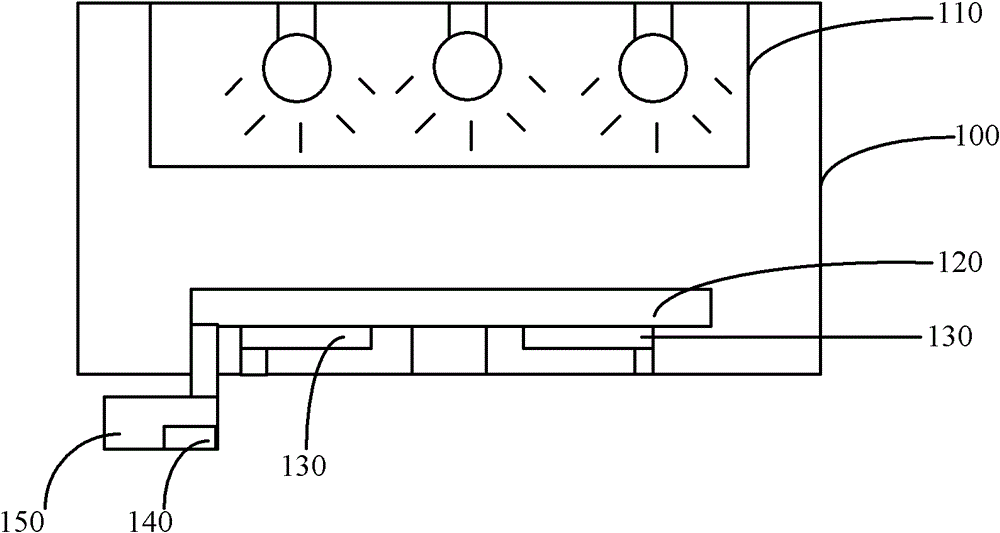

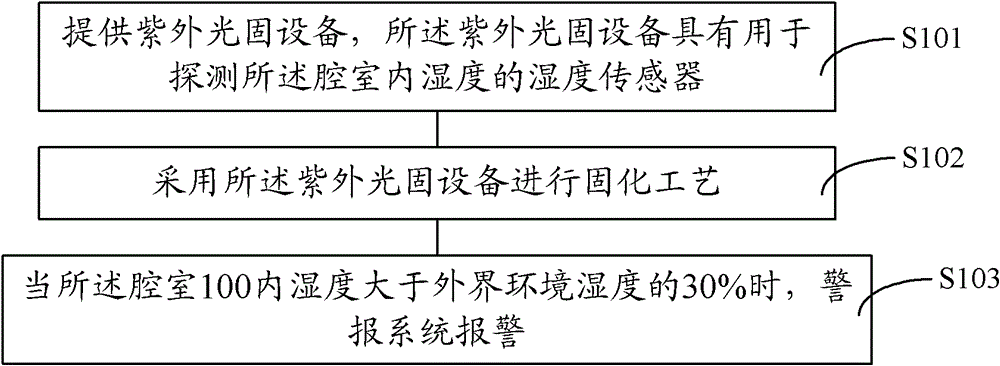

[0018] The inventors of the present invention have found in actual work that the scrap rate of substrates baked by existing ultraviolet light curing equipment is high. The inventors further analyzed the scrapped substrates and found that all scrapped substrates have water stains. The substrate was contaminated during the photocuring process due to water leakage.

[0019] For this reason, the inventors of the present invention have further researched and found that the reason for the water leakage of the UV curing equipment and the formation of water stains on the substrate is that during the UV curing process, the substrate is placed on the surface of the UV curing equipment. substrate carrier (wafer chuck), and when UV curing is performed, the water cooling system of the substrate carrier cools the substrate through water cooling. When the cooling system leaks, the cooling water will spread to the The substrate is placed on the tray, causing the substrate to be polluted by wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com