Low temperature co-fired ceramic (LTCC) filter production process and LTCC filter

A manufacturing process and filter technology, applied to waveguide devices, impedance networks, electrical components, etc., can solve problems such as high cost, achieve high conductivity, increase degrees of freedom, and reduce disconnection and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

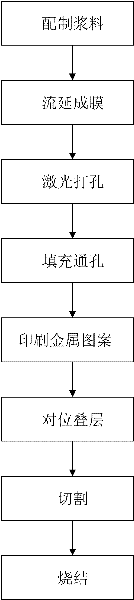

Method used

Image

Examples

Embodiment 1

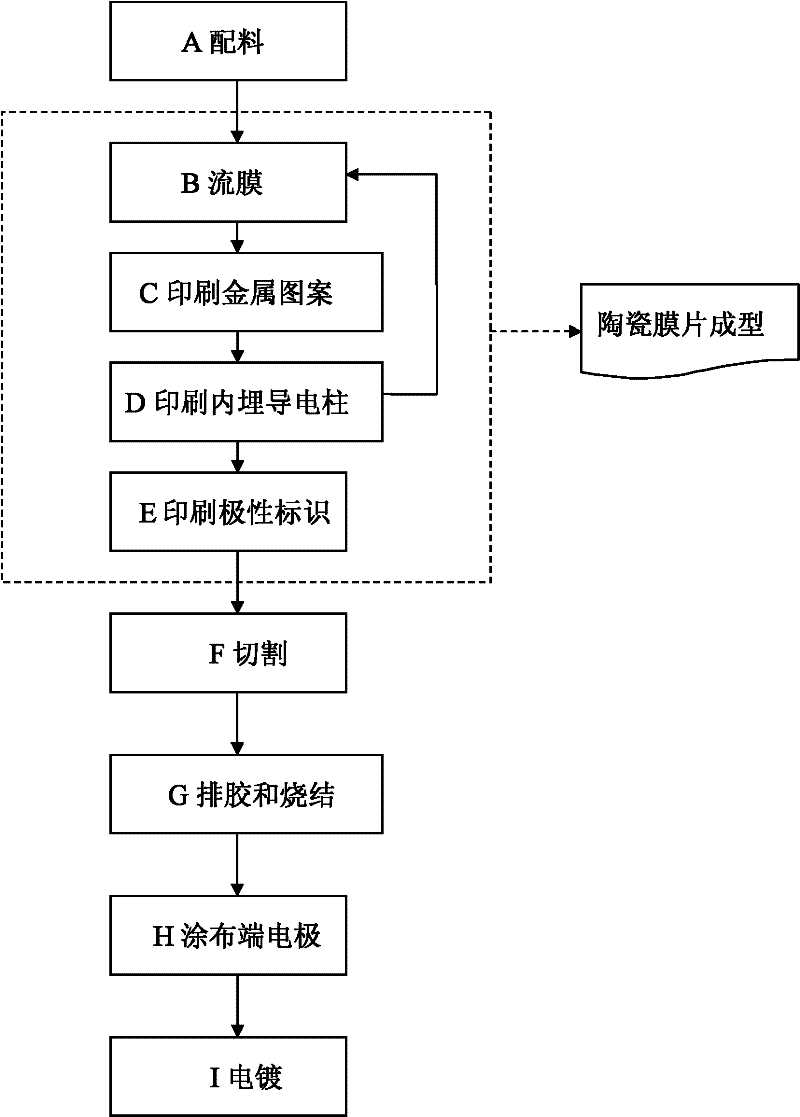

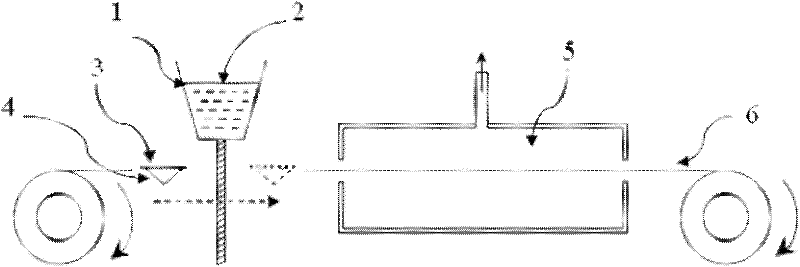

[0074] Among them, steps B, C, D, and E are ceramic diaphragm forming steps, refer to Figure 5 As shown in , a specific production process is taken as an example to describe in detail. First, step B is carried out, and the ceramic slurry is cast into a ceramic diaphragm, and the casting is repeated to form a ceramic substrate 101 with a certain thickness, which we call the lower substrate; Step C is performed on the lower substrate, and Ag The paste is printed into a metal pattern to form a grounding conductor 102; then step D is performed several times, and the method of printing a metal bump with a printed Ag paste—a method of covering a ceramic film is repeated for a certain number of times to form the first embedded conductive column 103; and then operate Step C, printing the first capacitive substrate 104 and the second capacitive substrate 105; followed by step D, printing the embedded conductive pillars to form the second embedded conductive pillars 106 and the third e...

Embodiment 2

[0077] refer to Image 6 , and combined with Figure 4 As shown in , another specific manufacturing step for forming the ceramic diaphragm is as follows: firstly cast ceramic slurry to form a ceramic raw material film, repeat casting to form the lower substrate 201; print metal patterns on the substrate to form the ground shielding layer 202, The coating electrode 202 will be connected to the external ground terminal electrodes 24, 25; the plate electrodes 203, 204 and the ground shielding layer 202 form two ground capacitances; the plate electrodes 207, 208 and the lead-out electrodes 211, 212 form input / output electrodes respectively , wherein the lead-out electrodes 211, 212 will be connected to the input and output electrodes 22, 23; the plate electrodes 207, 208 are respectively connected to the plate electrodes 213, 214 through a group of embedded conductive columns 209, 210; the plate electrodes 213, 214 are connected to the lead-out electrodes 211, 212 form an input / o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com