Quantum dot solid film and method for preparing quantum dot solid film and QLED device

A technology of quantum dots and solid films, which is applied in the field of quantum dot film preparation, can solve the problems of blank electrical devices of N-type quantum dot solid films, achieve high fluorescence intensity, increase fluorescence intensity, and change electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention provides a method for preparing a quantum dot solid film, the quantum dot solid film is an N-type quantum dot solid film, and the preparation method includes the following steps:

[0034] S01. Provide a kind of P-type quantum dot solid film;

[0035] S02. Soak the P-type quantum dot solid film in a quaternary ammonium halide solution to exchange ligands on the surface of the quantum dots, then dry and wash to obtain the N-type quantum dot solid film.

[0036] Specifically, in the above step S01, the P-type quantum dot solid film can be prepared by the following method:

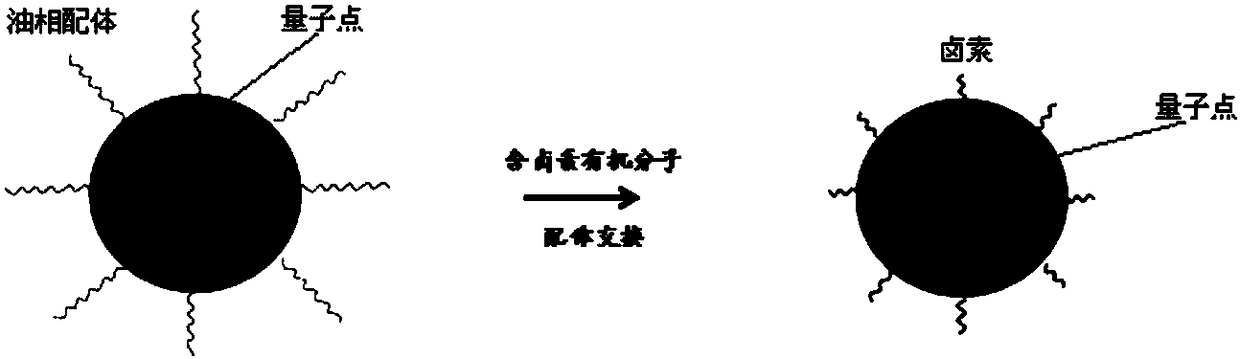

[0037] Quantum dots are provided, and the surface ligands of the quantum dots are oil phase ligands;

[0038] The quantum dots are configured into a quantum dot solution, deposited on a substrate, and then dried to obtain a P-type quantum dot solid film.

[0039] Wherein, the quantum dots are quantum dots with oil phase ligands on the surface, including binary p...

Embodiment 1

[0083] A preparation method of NPN type quantum dot solid film, comprising the following steps:

[0084] Step 1. provides oil-soluble CdSe quantum dots, and the preparation method of the oil-soluble CdSe quantum dots is as follows:

[0085] Cadmium Oleate Cd(OA) 2 Precursor preparation: Add 2mmol of cadmium oxide, 3ml of oleic acid, and 10ml of octadecene into a three-necked flask, first vacuumize at room temperature for 30mins, heat to 180°C and exhaust argon for 60mins, maintain 180°C for 30mins, cool to room temperature for later use .

[0086] Preparation of selenium (Se) precursor: 4 mmol of Se was added to 4 ml of trioctylphosphine, heated to 170° C. for 30 minutes, and then cooled to 140° C.

[0087] Preparation of CdSe quantum dots: Heating the cadmium oleate precursor to 280°C, then extracting 2ml of the selenium precursor and injecting it into the cadmium oleate precursor to react for 2 minutes. The toluene was subjected to centrifugal separation and drying treatm...

Embodiment 2

[0095] A preparation method of NPN type quantum dot solid film, comprising the following steps:

[0096] Step 1. Preparation of CdTe quantum dots

[0097] Preparation of Cd 2+ CdCl with a concentration of 0.1mol / L 2 Aqueous solution, concentration is the 3-mercaptopropionic acid aqueous solution of 0.2mol / L, standby;

[0098] Freshly prepared NaHTe solution: NaBH with a molar ratio of 4.5:1 4 Dissolve Te powder in ultrapure water and react at room temperature for 5 hours to obtain NaHTe solution;

[0099] Preparation of CdTe: Take 5mL CdCl 2 Solution, 4.5mL of 3-mercaptopropionic acid solution was adjusted to 30mL to make mixed solution A, transferred to a 50mL three-necked flask, adjusted to pH 10.5 with NaOH solution, passed argon gas into the three-necked flask for deoxygenation for 1 hour, and added freshly prepared NaHTe solution 100 μL, stored at 4°C for 17 hours. Add 60 mL of absolute ethanol, centrifuge at 10,000 r / min for 15 min, repeat centrifugation, wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com