Impurity extraction method for caprolactam production

A caprolactam and extraction technology is applied in the directions of separation/purification of lactam, chemical instruments and methods, liquid solution solvent extraction, etc., can solve problems such as high cost and unsatisfactory extraction effect, and achieves convenient operation, easy implementation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

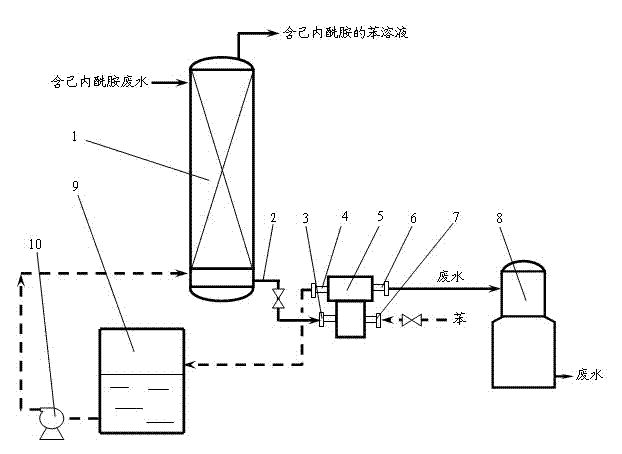

[0022] Attached figure 1 In the extraction process shown, the volume flow rate of wastewater containing caprolactam is 6.0m 3 / h, the content of caprolactam is 48%, the water content is about 50%, the rest is ammonium sulfate and organic impurities, and the density of the mixture is 1028kg / m 3 , the temperature is 40±5℃. Benzene volume flow rate 36.0mm 3 / h, density 872kg / m 3 , the temperature of the centrifugal extraction and separation is 40°C, the rotational speed of the motor of the centrifugal extraction separator is 1200r / min, and the operating pressure of the centrifugal extraction separator is: 0.01-0.20MPa.

[0023] Caprolactam content adopts gas chromatography, referring to DSM385-E and 385-02-E and DSM657-E. After extraction, the content of caprolactam in the waste water is less than 0.5% (weight ratio), and the content of unsaturated benzene in the waste water is not more than 0.1% (weight ratio).

Embodiment 2

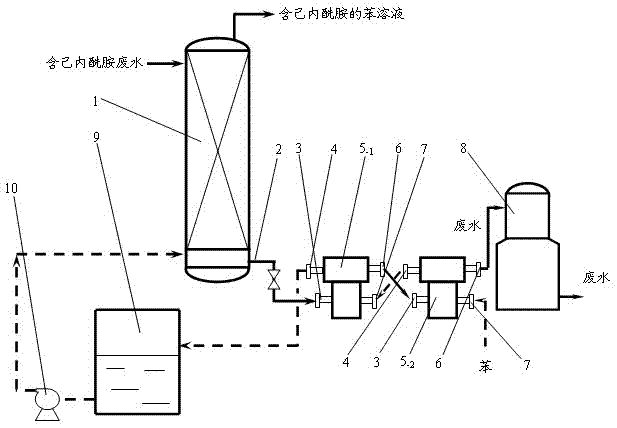

[0025] Attached figure 2 In the extraction process shown, the volume flow rate of wastewater containing caprolactam is 6.0 m 3 / h, the content of caprolactam is 48%, the water content is about 50%, the rest is ammonium sulfate and organic impurities, and the density of the mixture is 1028kg / m 3 , the temperature is 40±5℃. Benzene volume flow rate 36.0 m 3 / h, density 872kg / m 3 , the temperature of the centrifugal extraction and separation is 40°C, the rotational speed of the motor of the centrifugal extraction separator is 1200r / min, and the operating pressure of the centrifugal extraction separator is: 0.01-0.20MPa.

[0026] Caprolactam content adopts gas chromatography, referring to DSM385-E and 385-02-E and DSM657-E. After extraction, the content of caprolactam in the waste water is less than 0.3% (weight ratio), and the content of unsaturated benzene in the waste water is not more than 0.1% (weight ratio).

Embodiment 3

[0028] Attached figure 1 For the extraction process shown, the volumetric flow rate of wastewater containing caprolactam is 3.5 m 3 / h, the content of caprolactam is 48%, the water content is about 50%, the rest is ammonium sulfate and organic impurities, and the density of the mixture is 1028kg / m 3 , the temperature is 40±5℃. Benzene volume flow rate 15.0 m 3 / h, density 872kg / m 3 , the temperature of the centrifugal extraction and separation is 40°C, the rotational speed of the motor of the centrifugal extraction separator is 900r / min, and the operating pressure of the centrifugal extraction separator is: 0.01-0.20MPa.

[0029] Caprolactam content adopts gas chromatography, referring to DSM385-E and 385-02-E and DSM657-E. After extraction, the content of caprolactam in the waste water is less than 0.7% (weight ratio), and the content of unsaturated benzene in the waste water is not more than 0.2% (weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com