Gasoline composition and preparation method thereof

A composition and gasoline technology, applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve the problems of undisclosed gasoline engine fuel performance indicators, unfavorable reduction of gasoline olefin content, and no significant increase in octane number , to achieve the effects of flexible use, improved anti-knock performance, and increased octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] The present invention also provides a method for preparing a gasoline composition, the method comprising the step of adding sec-butyl acetate to raw gasoline, based on the total amount of the gasoline composition, the added amount of the sec-butyl acetate is such that The content of sec-butyl acetate in the gasoline composition is 1-30% by weight, and the content of the raw gasoline is 70-99% by weight.

[0095] The present invention is not particularly limited to the method for adding sec-butyl acetate in raw material gasoline, can be the various methods known to those skilled in the art, as long as raw material gasoline and sec-butyl acetate can be mixed homogeneously and make the sec-butyl acetate The content can be within the specified range. For example, in a mixer, under the condition of stirring, slowly add a predetermined amount of sec-butyl acetate into the raw gasoline and stir evenly; it is also possible to add sec-butyl acetate and raw gasoline into the mixe...

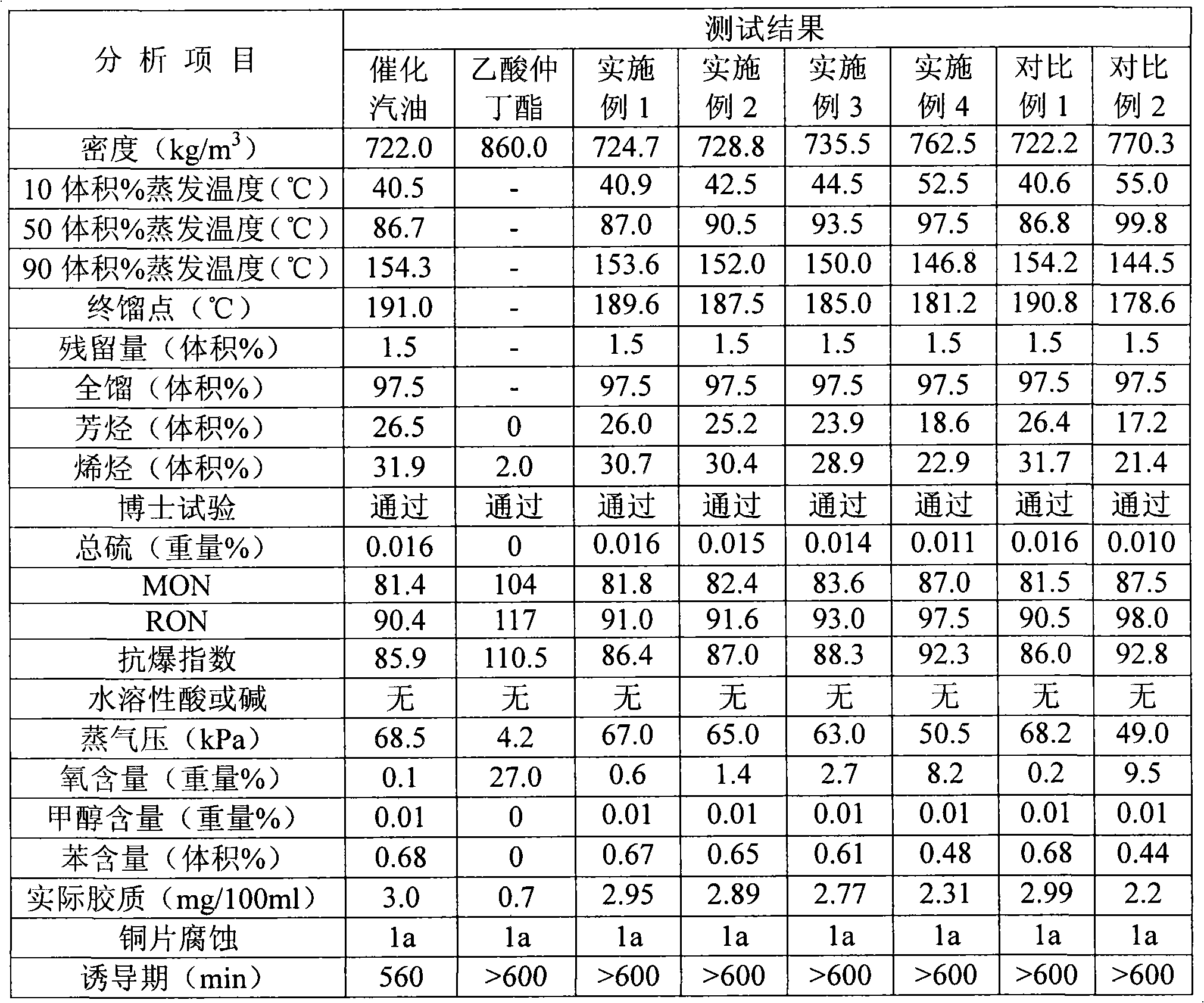

Embodiment 1

[0105] This example serves to illustrate the gasoline composition and method for its preparation according to the present invention.

[0106] In this embodiment, sec-butyl acetate with a purity of 97.8% by weight commercially purchased from Hunan Zhongchuang Chemical Co., Ltd. is used. The physical and chemical parameters of the sec-butyl acetate are shown in Table 3 below.

[0107] 2 parts by weight of sec-butyl acetate are added to 98 parts by weight of raw gasoline (catalytic cracking hydrogenated gasoline provided by Sinopec Changling Branch), and after mixing uniformly, gasoline composition of the present invention is obtained. In this gasoline composition, acetic acid The content of sec-butyl ester was 2% by weight, and the various technical indicators of the obtained gasoline composition containing sec-butyl acetate are shown in Table 3 below.

Embodiment 2

[0109] This example serves to illustrate the gasoline composition and method for its preparation according to the present invention.

[0110] The present embodiment adopts the raw material gasoline and sec-butyl acetate identical with embodiment 1.

[0111] The sec-butyl acetate of 5.1 parts by weight is added in the raw material gasoline of 94.9 parts by weight, after mixing uniformly, the gasoline composition of the present invention is obtained, and the content of sec-butyl acetate in this gasoline composition is 5% by weight, and the obtained gasoline composition contains acetic acid The various technical indicators of the gasoline composition of sec-butyl ester are shown in Table 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com