Suspended spraying type metal organic chemical vapor deposition (MOCVD) reactor

A technology of reactors and reaction zones, applied in the direction of chemically reactive gases, chemical instruments and methods, gaseous chemical plating, etc., can solve the problem of composition and thickness uniformity that affect film growth, and it is difficult to produce thin and uniform concentration boundaries layer, affecting the uniformity of flow, etc., to reduce cleaning and maintenance time, improve uniformity and source material utilization, and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

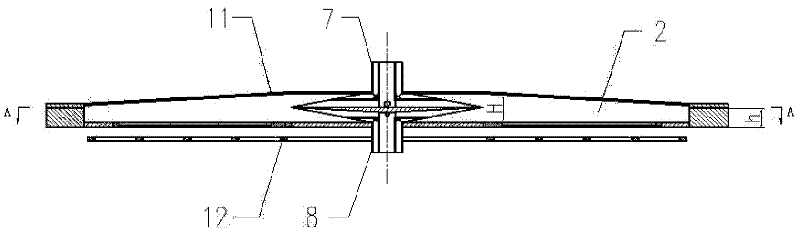

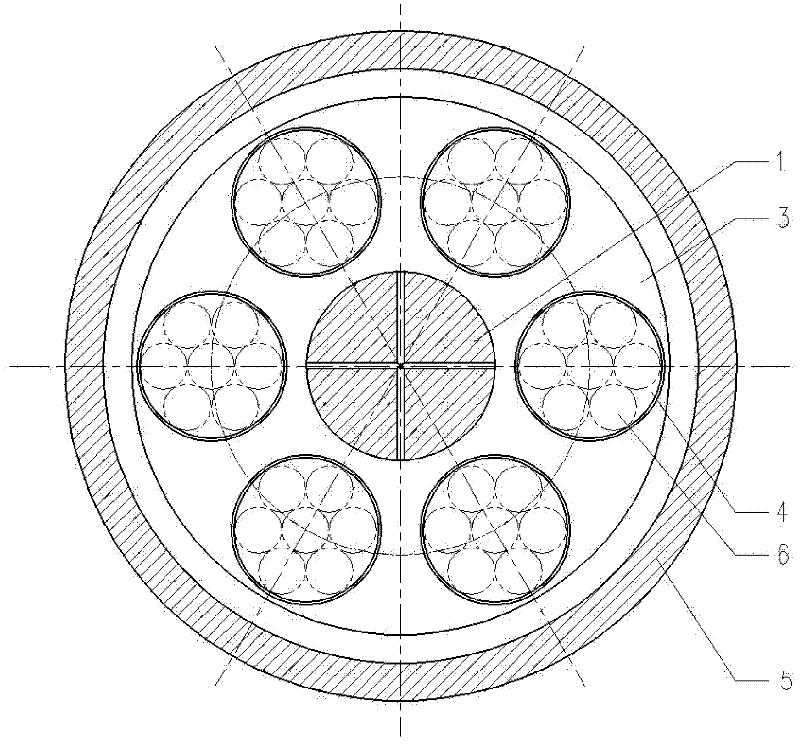

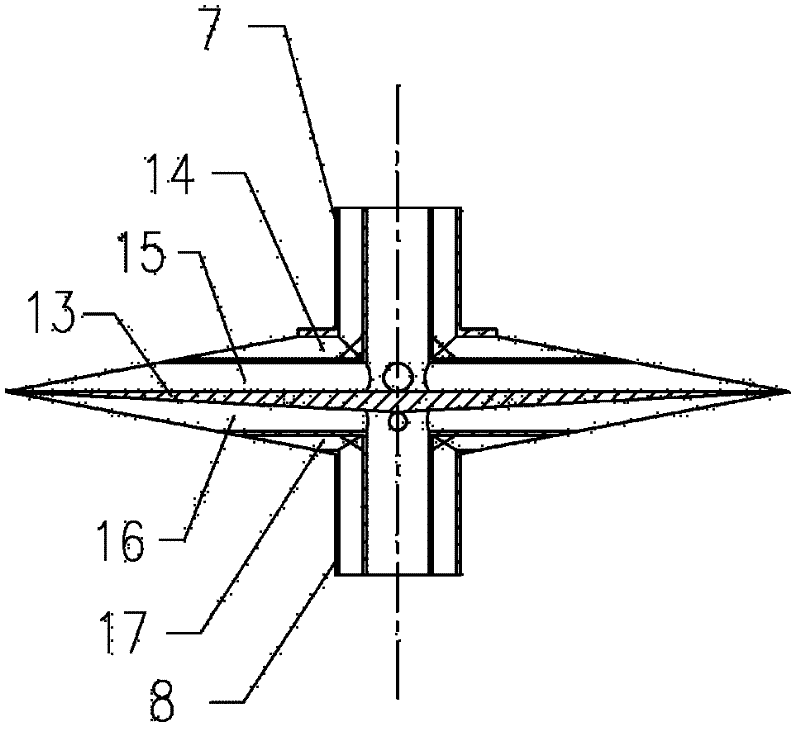

[0029] Such as Figure 1-Figure 4 Shown, a kind of suspended spray type MOCVD reactor comprises nozzle 1, base 19, cover plate 11, diversion hole 18 and reaction zone 2, and described nozzle 1 places base 19 center, and nozzle comprises upper nozzle 7 and The lower nozzle 8, the lower nozzle 8 is located at the bottom of the upper nozzle 7, and the upper nozzle and the lower nozzle are respectively provided with two radial passages; the base 19 includes a large graphite disc 3, which is arranged in the circumferential direction There are small graphite disks 4, each small graphite disk 4 is provided with a wafer substrate 6 along the circumferential direction, the bottom of the large graphite disk 3 is provided with a revolution drive mechanism 20, and the bottom of each small graphite disk 4 is provided with a rotation drive mechanism 22; The internal wall is provided with diversion holes 18 along the circumferential direction.

[0030] The top of the lower nozzle 8 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com