Aluminum alloy sacrificial anode suitable for sea mud in Bohai Sea Gulf

A sacrificial anode and aluminum alloy technology, applied in the field of metal anti-corrosion, can solve the problem of less research on sacrificial anode materials, and achieve the effect of prolonging the life of the anode, good protection effect, and saving anode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for manufacturing an aluminum alloy sacrificial anode suitable for Bohai Bay sea mud. Weigh 2.5% zinc; 0.01% indium; 0.08% tin; 4% magnesium; 0.12% lanthanum; 0.12% actinium; 0.03% cerium; 0.04% silicon, 93.1% aluminum.

[0018] Wrap indium, tin, magnesium, lanthanum, actinium, and cerium with aluminum foil, put them into the molten aluminum, and then put zinc into the molten aluminum. After the alloy is completely melted, check that the impurity silicon content is 0.04%; The molten alloy is poured into a mold and cast into an aluminum alloy sacrificial anode body. The weight of the aluminum foil is included in the component aluminum.

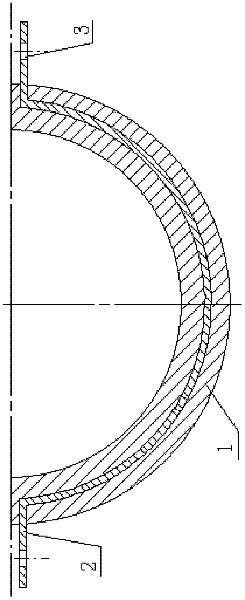

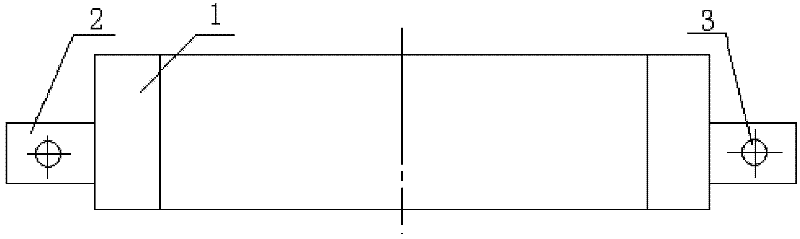

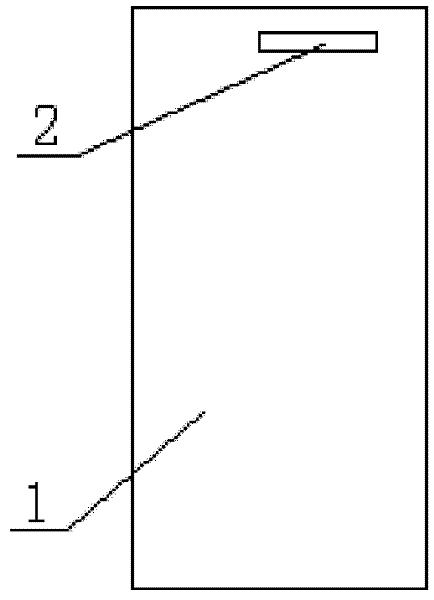

[0019] refer to figure 1 . The aluminum alloy sacrificial anode body includes a sacrificial anode 1 and a connecting plate 2. The sacrificial anode 1 is a semi-circular cylinder, that is, the cross section of the sacrificial anode 1 is a semi-circular ring, and two semi-circular sacrificial anodes 1 are opposite to form a hol...

Embodiment 2

[0024] A method for manufacturing an aluminum alloy sacrificial anode suitable for Bohai Bay sea mud. Weigh 4% zinc; 0.05% indium; 0.05% tin; 6% magnesium; 0.2% lanthanum; 0.2% actinium; 0.03% cerium, 89.44% aluminum; 0.03% silicon. Lanthanum, actinium and cerium are products of Baotou Iron and Steel (Group) Co., Ltd.

[0025] Alloy indium, tin, magnesium, lanthanum, actinium, and cerium, press the alloy into the molten aluminum, and then put zinc into the aluminum melt. After the alloy is completely melted, check that the silicon is 0.03%; The molten alloy is poured into a mold and cast into an aluminum alloy sacrificial anode body.

[0026] The aluminum alloy sacrificial anode body includes a sacrificial anode 1 and a connecting plate 2. The sacrificial anode 1 is a semi-circular cylinder, that is, the cross section of the sacrificial anode 1 is a semi-circular ring, and two semi-circular sacrificial anodes 1 are opposite to form a hollow cylinder. The inner diameter of th...

Embodiment 3

[0031] A method for manufacturing an aluminum alloy sacrificial anode material suitable for Bohai Bay sea mud. Weigh 5% zinc; 0.03% indium; 0.02% tin; 8% magnesium; 0.29% lanthanum; 0.30% actinium; 0.04% cerium, 86.27% aluminum; silicon content 0.05% . Lanthanum, actinium and cerium are products of Baotou Iron and Steel (Group) Co., Ltd.

[0032] Alloy indium, tin, magnesium, lanthanum, actinium, and cerium, press the alloy into the molten aluminum, and then put zinc into the aluminum melt. After the alloy is completely melted, check that the silicon is 0.05%; The molten alloy is poured into a mold and cast into an aluminum alloy sacrificial anode body. The weight of the aluminum foil is included in the component aluminum.

[0033]The aluminum alloy sacrificial anode body includes a sacrificial anode 1 and a connecting plate 2. The sacrificial anode 1 is a semi-circular cylinder, that is, the cross section of the sacrificial anode 1 is a semi-circular ring, and two semi-cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com