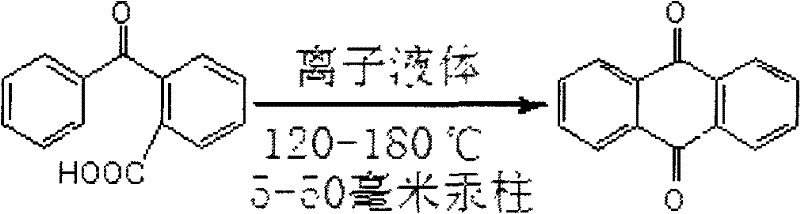

Method for synthesizing anthraquinone

A synthesis method and anthraquinone technology are applied in the field of organic compound preparation, can solve problems such as unreported synthetic application of anthraquinone, and achieve the effects of low cost, simplified post-processing steps, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 5g (35mmol) of dimethylamine sulfate and 1.13g (5mmol) of o-benzoylbenzoic acid into a flask, install a condenser tube, and connect it to the decompression system. Then, under the pressure of 5mmHg, it was heated to 120° C., and after 5 hours of reaction, the heating was stopped and the pressure was returned to atmospheric pressure. 0.84 g of product anthraquinone was collected from the condenser tube, and the yield was 80.8%.

Embodiment 2

[0017] Add 5g (about 29mmol) of diethylamine sulfate and 1.13g (5mmol) of o-benzoylbenzoic acid into a flask, install a condenser tube, and connect it to the decompression system. Then, under the pressure of 10 mmHg, heat to 130° C., and after 5 hours of reaction, stop heating and return the pressure to atmospheric pressure. 0.80 g of product anthraquinone was collected from the condenser tube, and the yield was 76.9%.

Embodiment 3

[0019] Add 5g (25mmol) of triethylamine sulfate and 1.13g (5mmol) of o-benzoylbenzoic acid into a flask, install a condenser tube, and connect it to the decompression system. Then, under the pressure of 25 mmHg, heat to 150° C., after 3 hours of reaction, stop heating and return the pressure to atmospheric pressure. 0.75 g of product anthraquinone was collected from the condenser, and the yield was 72.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com