Preparation method of parthenolide

A parthenolide and ethyl acetate technology, applied in the direction of organic chemistry and the like, can solve the problems of complicated process, high production cost, and low parthenolide content, and achieve the effect of simple extraction and separation process and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

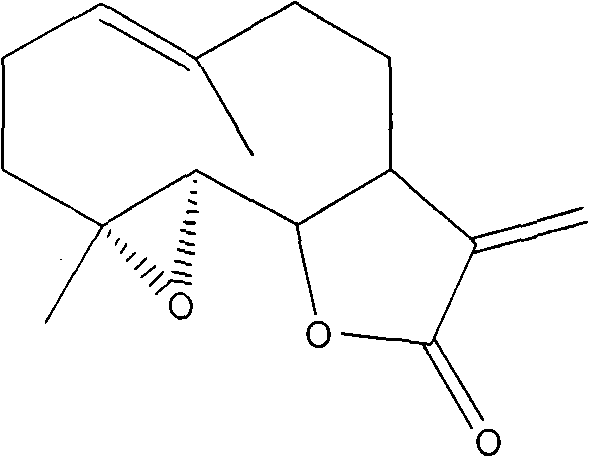

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of parthenolide

[0026] Take 1 kg of dry root bark of Magnolia Magnolia, and grind it into powder. Get the pulverized coarse powder, soak 3 times with 10 times (weight) of 95% ethanol at room temperature, each time for 72 hours. Filtrate, combine the filtrates, and recover the solvent under reduced pressure to obtain the extract. The extract was dissolved with 20% ethanol, then extracted with ethyl acetate until the color of the extract became lighter, the organic solvent was combined, the solvent was recovered under reduced pressure, and dried to obtain 104 grams of solid. Put on a silica gel chromatography column, elute with petroleum ether: ethyl acetate = 15:1 ~ 4:1 gradient, TLC tracking detection, compare with standard parthenolide, collect fractions containing parthenolide, combine and reduce pressure The solvent was recovered to obtain a dry solid. Crystallize in a mixed solvent of petroleum ether: acetone = 10:1 to obtain 50 g of c...

Embodiment 2

[0030] Embodiment 2: with the comparative embodiment of Guang Yulan dry leaf

[0031] In order to better illustrate the present invention, according to the method for extracting a parthenolide-rich extract disclosed in CN101190258, 2.5 g of parthenolide was isolated and purified from 1 kg of Magnolia glabra dry leaves, and the yield was only 0.25%. And the process is more loaded down with trivial details, and the production cost is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com