Equipment for producing reflection film with microprism array structure by using annular strip die

A strip mold and array structure technology, applied in optics, optical components, instruments, etc., can solve problems such as unfavorable reflective film processing and use, limited application range of reflective film, environmental impact, etc., to facilitate subsequent processing and use, The effect of low production cost and environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

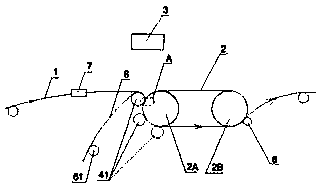

[0049] Such as figure 1 and Figure 7 As shown, the equipment for producing reflective film with a microprism array structure is produced with an annular belt mold, including an annular belt mold 2, a molding device and a coating device 3 of a hot-melt resin 12, and the annular belt mold 2 has an inner surface 21 And an outer surface 22, the outer surface 22 has a concave continuous microprism array structure 23, the ring-shaped belt mold 2 is installed on the support roller 2A and the support roller 2B arranged in parallel, forming a closed loop reciprocating motion, two The support rolls are all hollow rigid rolls, made of steel, copper or iron materials, the inside of the support roll 2A near the entrance of the resin film 1 passes through the cooling medium, and away from the support roll 2B at the entrance of the resin film 1 The inside passes through the cooling medium, and the outer surface of one end of the support roll 2B away from the entrance of the resin film 1 on...

Embodiment 2

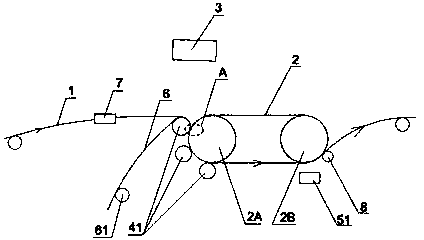

[0061] Such as figure 2 and Figure 7 As shown, the equipment for producing reflective film with a microprism array structure is produced with an annular belt mold, including an annular belt mold 2, a molding device and a coating device 3 of a hot-melt resin 12, and the annular belt mold 2 has an inner surface 21 And an outer surface 22, the outer surface 22 has a concave continuous microprism array structure 23, the ring-shaped belt mold 2 is installed on the support roller 2A and the support roller 2B arranged in parallel, forming a closed loop reciprocating motion, two The support rolls are all hollow rigid rolls, made of steel, copper or iron materials, and the inside of the support roll 2A near the entrance of the resin film 1 passes through the cooling medium. One end outer surface of the support roll 2B at the entrance of the ester film 1 is provided with an external cold air spray device 51, and after the cold air spray device 51 cools the hot melt resin 12, one side...

Embodiment 3

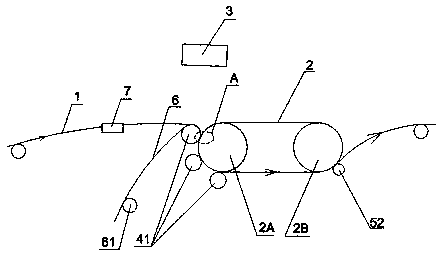

[0073] Such as image 3 and Figure 7 As shown, the equipment for producing reflective film with a microprism array structure is produced with an annular belt mold, including an annular belt mold 2, a molding device and a coating device 3 of a hot-melt resin 12, and the annular belt mold 2 has an inner surface 21 And an outer surface 22, the outer surface 22 has a concave continuous microprism array structure 23, the ring-shaped belt mold 2 is installed on the support roller 2A and the support roller 2B arranged in parallel, forming a closed loop reciprocating motion, two The support rolls are all hollow rigid rolls, made of steel, copper or iron materials, and the inside of the support roll 2A near the entrance of the resin film 1 passes through the cooling medium. One end outer surface of the support roll 2B at the entrance of the ester film 1 is provided with an external hollow rigid roll 52 that passes through the cooling medium, made of steel, copper or iron material, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com