Method and device for recycling Freon from rigid foam insulating material of waste and old refrigerator and ice tank

A thermal insulation material and freon technology, applied in the field of separation and recovery of freon, can solve the problems of strong corrosion of equipment, high equipment maintenance and operation costs, waste gas treatment costs, toxic and harmful substances in thermal insulation materials, etc., to achieve efficient separation, avoid high energy consumption and environmental pollution. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

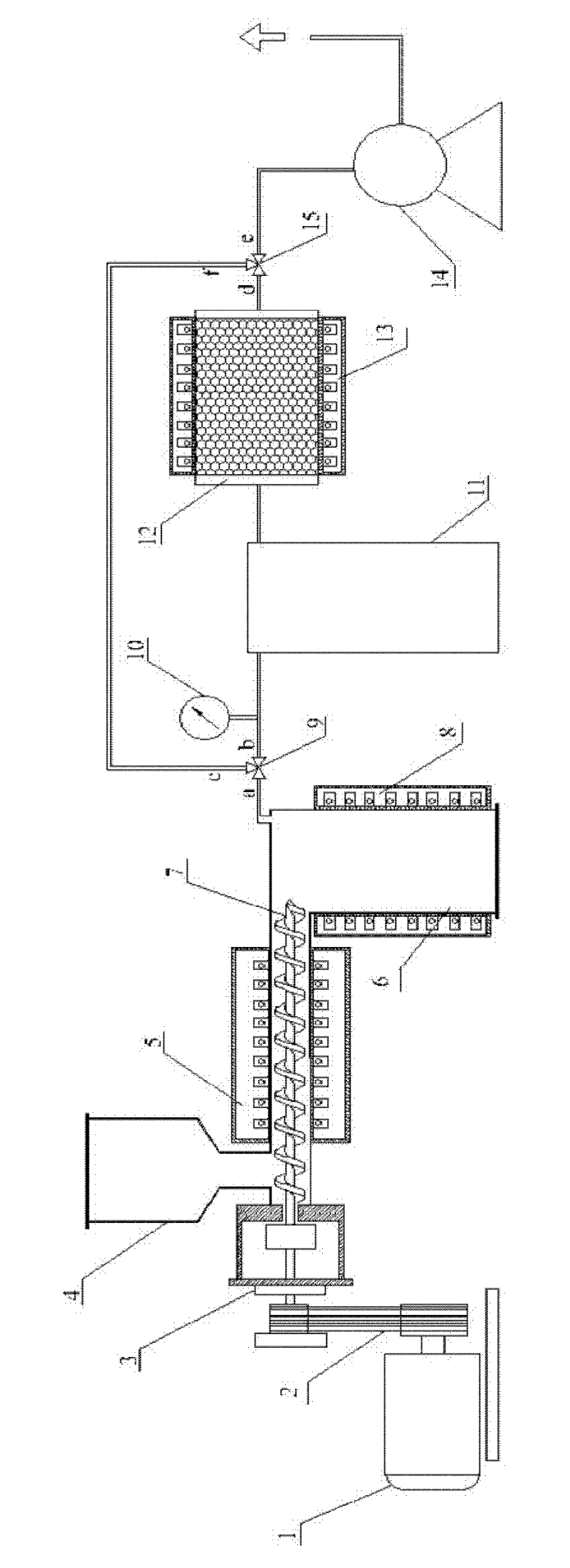

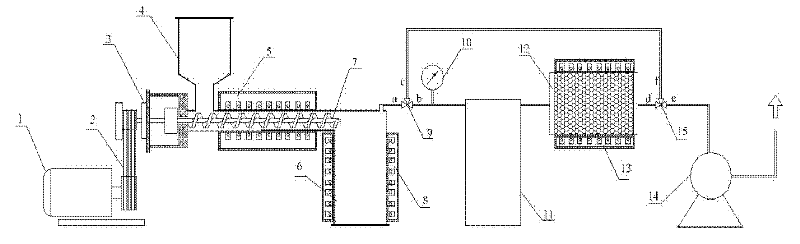

[0035] 1. Put the granular hard foam insulation material (with a particle size range of 2 to 5mm) into the hopper 4 and connect the whole equipment. The No. 1 three-way valve 9 connects ab and closes c, and the second three-way valve 15 opens de and closes f , turn on the vacuum pump 14 to make the system in a vacuum state, the system pressure is 30Pa, turn on the No. 1 heating unit 5 and No. 2 heating unit 8 to heat the incoming material, the heating temperature is 100 ° C, turn on the motor 1, and use the screw feeder 7 to feed the hard The foam insulation material is slowly sent into the defluorination reactor 6;

[0036] 2. Incoming materials are subjected to heat preservation treatment in the defluorination reactor 6, the heat preservation temperature is 100°C, and the heat preservation time is 30 minutes;

[0037] 3. Set the condensation temperature of the condensation recovery machine 11 to 20°C, and the gas after condensation recovery treatment is filtered by the activ...

Embodiment 2

[0040] 1. Put the granular hard foam insulation material (with a particle size range of 2 to 5mm) into the hopper 4 and connect the whole equipment. The No. 1 three-way valve 9 connects ab and closes c, and the second three-way valve 15 opens de and closes f , turn on the vacuum pump 14 to make the system in a vacuum state, the system pressure is 20Pa, turn on the No. 1 heating unit 5 and No. 2 heating unit 8 to heat the incoming materials, the heating temperature is 120 ° C, turn on the motor 1, and use the screw feeder The foam insulation material is slowly sent into the defluorination reactor 6;

[0041] 2. Incoming materials are subjected to heat preservation treatment in the defluorination reactor 6, the heat preservation temperature is 120°C, and the heat preservation time is 1h;

[0042] 3. Set the condensation temperature of the condensation recovery machine 11 to 10°C, and the gas after condensation recovery treatment is filtered by the activated carbon adsorption box...

Embodiment 3

[0045] 1. Put the granular hard foam insulation material (with a particle size range of 2 to 5mm) into the hopper 4 and connect the whole equipment. The No. 1 three-way valve 9 connects ab and closes c, and the second three-way valve 15 opens de and closes f , turn on the vacuum pump 14 to make the system in a vacuum state, the system pressure is 10Pa, turn on the No. 1 heating unit 5 and No. 2 heating unit 8 to heat the incoming material, the heating temperature is 140 ° C, turn on the motor 1, and use the screw feeder The foam insulation material is slowly sent into the defluorination reactor 6;

[0046] 2. Incoming materials are subjected to heat preservation treatment in the defluorination reactor 6, the heat preservation temperature is 140°C, and the heat preservation time is 1.5h;

[0047] 3. Set the condensation temperature of the condensation recovery machine 11 to 0°C, and the gas after condensation recovery treatment is filtered by the activated carbon adsorption box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com