Surface modification method for quartz fibre

A quartz fiber and surface modification technology, which is applied in the field of quartz fiber composite materials, can solve problems affecting the interfacial bonding force of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

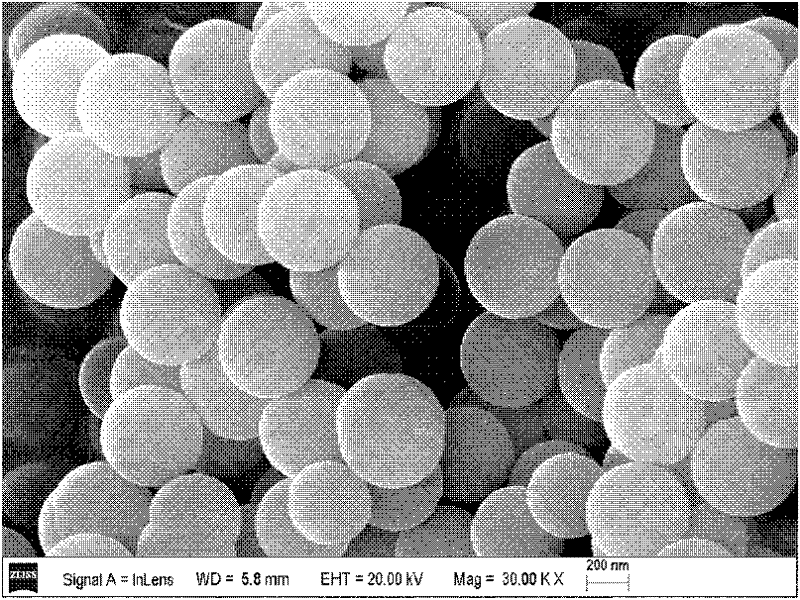

[0026] (1) Preparation of 200nm silica spheres (stober method)

[0027] Mix a certain amount of ammonia water, water and ethanol in a three-necked round-bottomed flask, and stir in a magnetic stirrer at a constant temperature of 25°C for 10 minutes, then slowly drop in tetraethyl orthosilicate, then seal and stir until the reaction is complete, and let it stand for a while. for 3-6h, centrifuged, and finally the SiO 2 The precipitate is washed to neutrality, and dried at room temperature -100°C to obtain 200nm monodisperse SiO 2 small ball.

[0028] Tetraethyl silicate molar concentration: 0.03mol / L

[0029] Molar concentration of ammonia water: 0.1mol / L

[0030] Deionized water concentration: 0.05mol / L

[0031] Response time: 240min

[0032] Stirring speed: 1000r / min

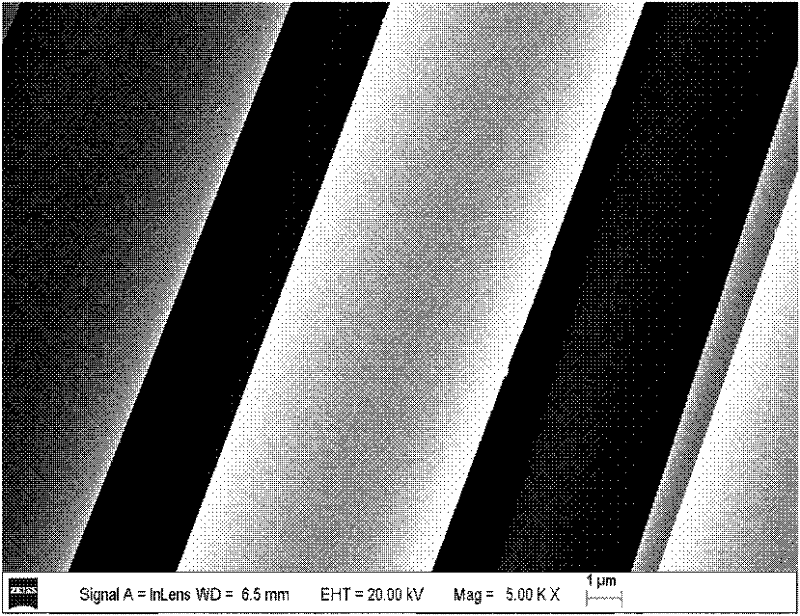

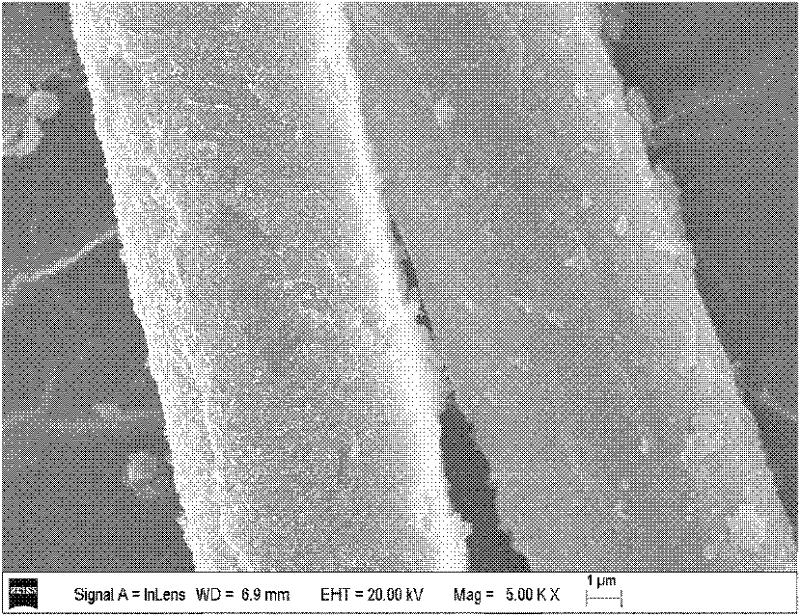

[0033] (2 surface treatment of quartz fiber

[0034] ① Ablation

[0035] Put the quartz fiber in a muffle furnace for heat treatment, burn candles at 400°C, keep the temperature for another 30 minutes, ...

Embodiment 2

[0044] (1) Preparation of 300nm silica spheres (stober method)

[0045] Mix a certain amount of ammonia water, water and ethanol in a three-necked round-bottomed flask, and stir in a magnetic stirrer at a constant temperature of 25°C for 10 minutes, then slowly drop in tetraethyl orthosilicate, then seal and stir until the reaction is complete, and let it stand for a while. for 3-6h, centrifuged, and finally the SiO 2 The precipitate is washed to neutrality, and dried at room temperature -100°C to obtain 300nm monodisperse SiO 2 small ball.

[0046] Tetraethyl silicate molar concentration: 0.03mol / L

[0047] Molar concentration of ammonia water: 0.05mol / L

[0048] Deionized water concentration: 0.7mol / L

[0049] Response time: 360min

[0050] Stirring speed: 600r / min

[0051] (2) Surface treatment of quartz fiber

[0052] ① Ablation

[0053] Put the quartz fiber in a muffle furnace for heat treatment, burn candles at 400°C, keep the temperature for another 30 minutes, an...

Embodiment 3

[0063] (1) Preparation of 400nm silica spheres (stober method)

[0064] Mix a certain amount of ammonia water, water and ethanol in a three-necked round-bottomed flask, and stir in a magnetic stirrer at a constant temperature of 25°C for 10 minutes, then slowly drop in tetraethyl orthosilicate, then seal and stir until the reaction is complete, and let it stand for a while. for 3-6h, centrifuged, and finally the SiO 2 The precipitate is washed to neutrality, and dried at room temperature -100°C to obtain 400nm monodisperse SiO 2 small ball.

[0065] Tetraethyl silicate molar concentration: 0.015mol / L

[0066] Molar concentration of ammonia water: 0.1mol / L

[0067] Deionized water concentration: 0.7mol / L

[0068] Response time: 480min

[0069] Stirring speed: 600r / min

[0070] (2) Surface treatment of quartz fiber

[0071] ① Ablation

[0072] Put the quartz fiber in a muffle furnace for heat treatment, burn candles at 400°C, keep the temperature for another 30 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com