Alkali-activated slag cement retarder and application method thereof

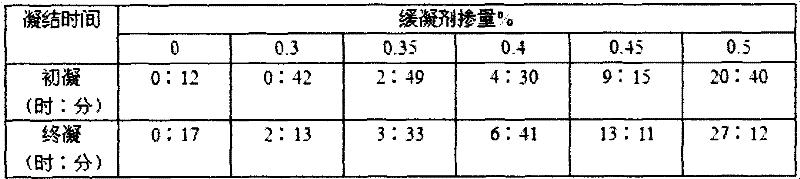

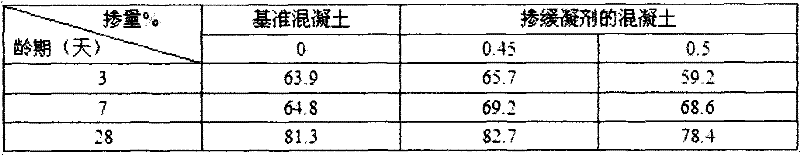

A technology of alkali slag cement and setting retarder, applied in the field of building materials, can solve the problems such as the limitation of the promotion and application of alkali slag cement, the lack of delaying effect of the setting of alkali slag cement, and the setting time that cannot meet the requirements of setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An alkali slag cement retarder, which comprises, by weight percentage: 25% of sodium chromate, 50% of sulfamic acid heterocyclic condensation product water reducer, and 25% of organic silicon surfactant.

Embodiment 2

[0027] An alkali slag cement retarder, which comprises, by weight percentage: 30% of sodium chromate, 40% of sulfamic acid heterocyclic condensation product water reducer, and 30% of organic silicon surfactant.

Embodiment 3

[0029] An alkali slag cement retarder, comprising 20% of sodium chromate, 50% of sulfamic acid heterocyclic condensation product water reducing agent and 30% of organosilicon surfactant by weight percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com