Powdered ink for laser printer and preparation method thereof

A laser printer and toner technology, applied in optics, electrography, instruments, etc., can solve the problems of inability to store for a long time, storage agglomeration, poor printing effect, etc., achieve good printing effect, reduce electrostatic attraction, and prevent the phenomenon of agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

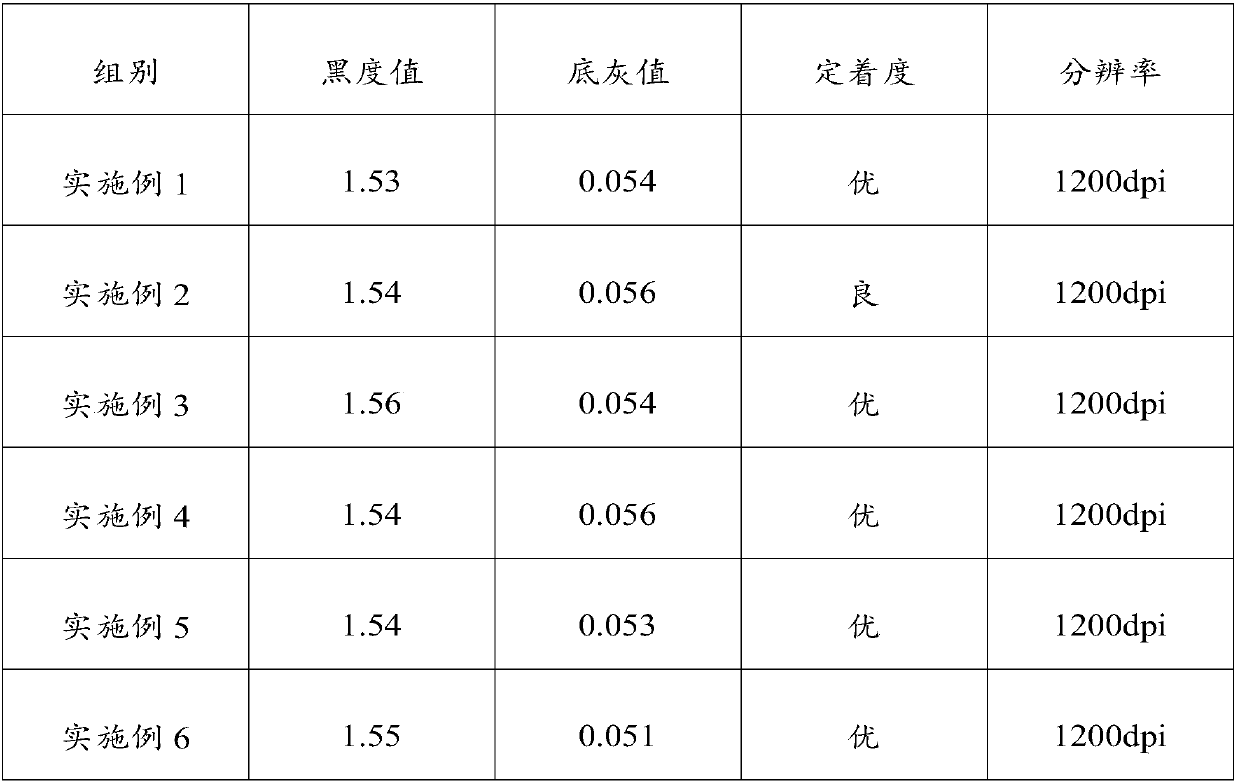

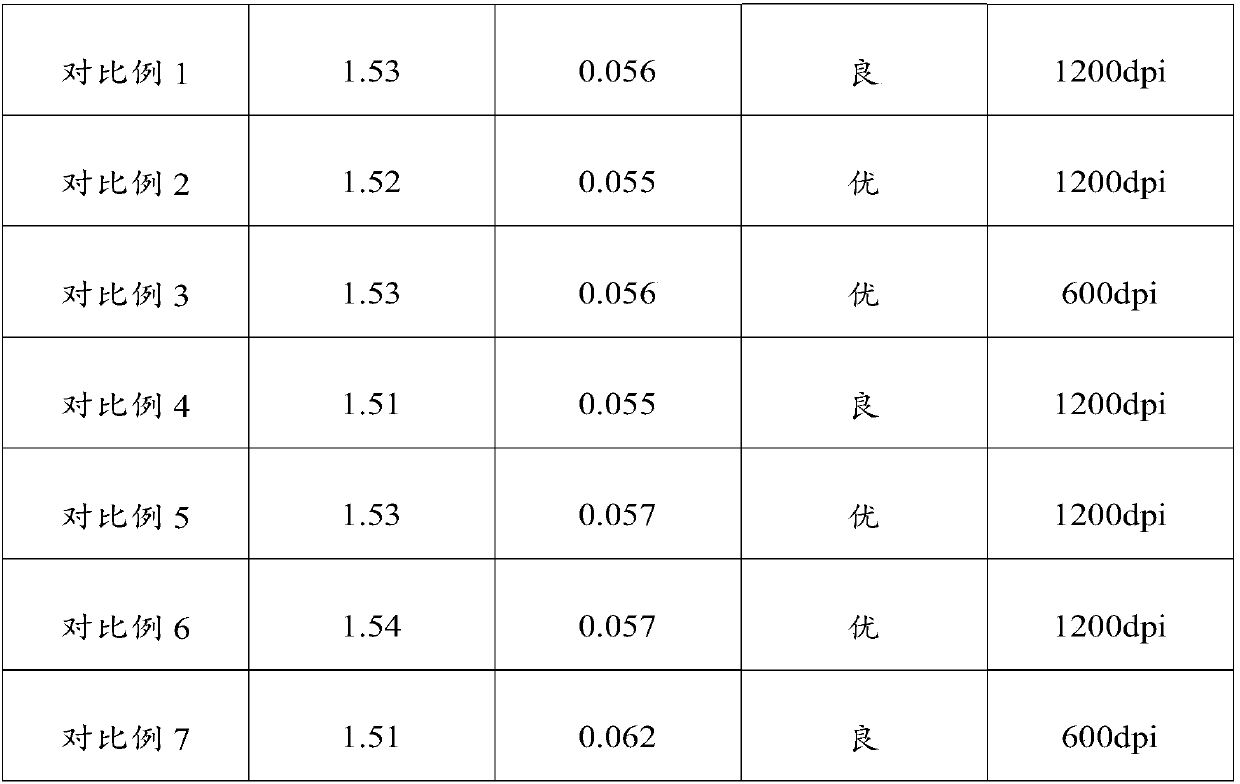

Examples

preparation example Construction

[0027] Embodiments of the present invention also provide a method for preparing a toner for a laser printer, comprising the following steps:

[0028] S1. After mixing 5-15 parts of hollow glass microspheres with a particle size of less than 2 microns, 15-30 parts of butyl acrylate and 20-30 parts of styrene, stir once at a temperature of 40-60°C for 2-5 hours Obtain adhesive mixed initial material.

[0029] It should be noted that the raw materials of the preparation method of toner for laser printers provided in the present invention adopt the raw material components and proportions in the introduction of the toner for laser printers described above, and are prepared by a simple and feasible production process. A toner product that prints well and is suitable for long-term storage.

[0030] The mixing of hollow glass microspheres, butyl acrylate and styrene is carried out at a higher temperature, which makes the mixing of hollow glass microspheres, butyl acrylate and styrene...

Embodiment 1

[0038] This embodiment provides a kind of toner for laser printer, the raw material of this toner for laser printer comprises: 13 parts of nano-carbon black, 15 parts of butyl acrylate, 5 parts of hollow glass microspheres, 3 parts of silicon dioxide , 1 part of polysorbate, 15 parts of styrene, 18 parts of azobisisobutyronitrile, 18 parts of polyvinyl alcohol and 8 parts of polypropylene wax; wherein, the particle diameter of the hollow glass microsphere is about 1 micron.

[0039] Present embodiment also provides a kind of preparation method for the toner of laser printer, it comprises the following steps:

[0040] After mixing 5 parts of hollow glass microspheres with a particle diameter of about 1 micron, 15 parts of butyl acrylate and 15 parts of styrene, they were stirred once at 40° C. for 5 hours to obtain an adhesive mixed raw material.

[0041] The adhesive mixed primary material was mixed with 13 parts of nano-carbon black, 3 parts of silicon dioxide, 1 part of poly...

Embodiment 2

[0043] This embodiment provides a kind of toner for laser printer, the raw material of this toner for laser printer comprises: 30 parts of nano-carbon black, 35 parts of butyl acrylate, 15 parts of hollow glass microspheres, 6 parts of silicon dioxide , 3 parts of polysorbate, 2 parts of quaternary ammonium salt, 30 parts of styrene, 35 parts of azobisisobutyronitrile, 30 parts of polyvinyl alcohol and 15 parts of polypropylene wax; among them, the particle size of hollow glass microspheres is about 1 micron.

[0044] Present embodiment also provides a kind of preparation method for the toner of laser printer, it comprises the following steps:

[0045] After mixing 15 parts of hollow glass microspheres with a particle diameter of about 1 micron, 35 parts of butyl acrylate and 30 parts of styrene, they were stirred once at 60° C. for 2 hours to obtain an adhesive mixed raw material.

[0046] Mix the raw adhesive with 30 parts of nano-carbon black, 6 parts of silicon dioxide, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com