Urea lose-control fertilizer, preparation method and production equipment thereof

A production device and loss-controlling fertilizer technology, applied in fertilization devices, urea compound fertilizer, nitrogen fertilizer, etc., can solve the problems of cumbersome operation and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

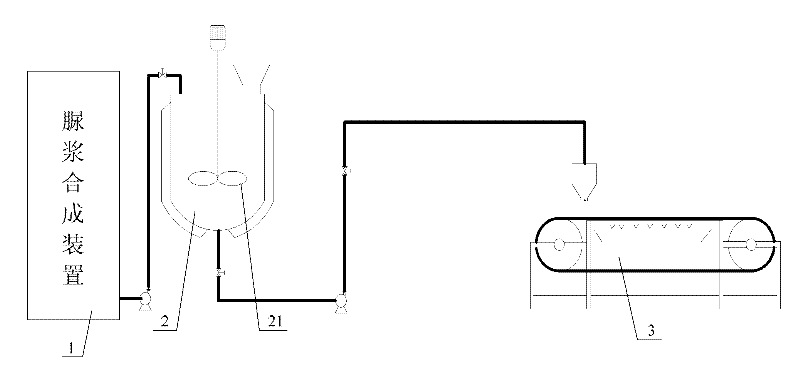

[0024] The embodiment of the present invention discloses a preparation method of urea for controlling loss of fertilizer, comprising the following steps:

[0025] a) introducing the urea slurry into the molten urea tank, heating and melting the urea tank and adding the loss control agent, stirring the urea slurry and the loss control agent evenly to obtain the loss control fertilizer urea slurry.

[0026] b) Send the urea slurry of the loss-controlling fertilizer into a granulation device for condensation and granulation to obtain urea loss-controlling fertilizer.

[0027] It can be seen from the above scheme that the present invention uses the urea slurry prepared by the urea production device in the urea production process as a raw material, imports the above-mentioned urea slurry into the molten urea tank to maintain a molten state, and adds a loss control agent to make the molten urea slurry and the control agent The loss-loss agent is mixed evenly to prepare the loss-cont...

Embodiment 1

[0042] 1. Send the urea slurry discharged from the second evaporator into the molten urea tank, and feed steam of 0.3Mpa to 0.4Mpa into the jacket of the molten urea tank to keep the temperature in the molten urea tank at 134°C to 136°C. A loss control agent is added into the molten urea tank, the weight ratio of the added loss control agent to the urea slurry is 5:100, and the stirring speed of the stirrer in the molten urea tank is set to 40 rpm to obtain a loss control fertilizer urea slurry.

[0043] 2. Send the loss-controlling fertilizer urea slurry in the molten urea tank to a rotary belt-type condensation granulator, and set the cooling water temperature to 35°C to obtain urea loss-controlling fertilizer.

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is that the weight ratio of the added loss control agent to urea slurry is 2:100, and the rest of the procedures are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com