Selective hydrogenation method of alkyne and dialkene in alkene stream

A technology for selective hydrogenation and diolefins, applied in chemical instruments and methods, processing of gas mixtures, processing of hydrocarbon oils, etc. The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

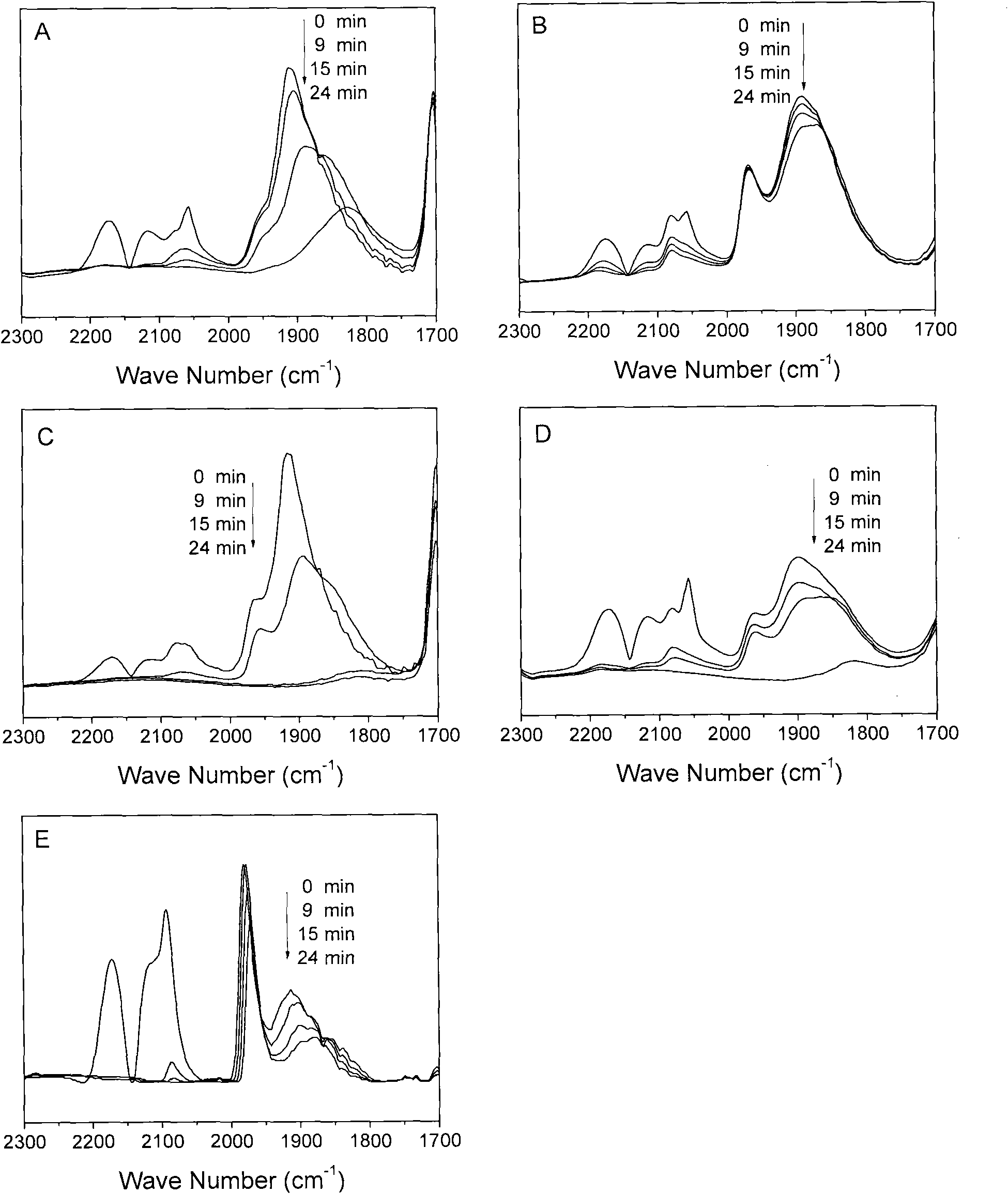

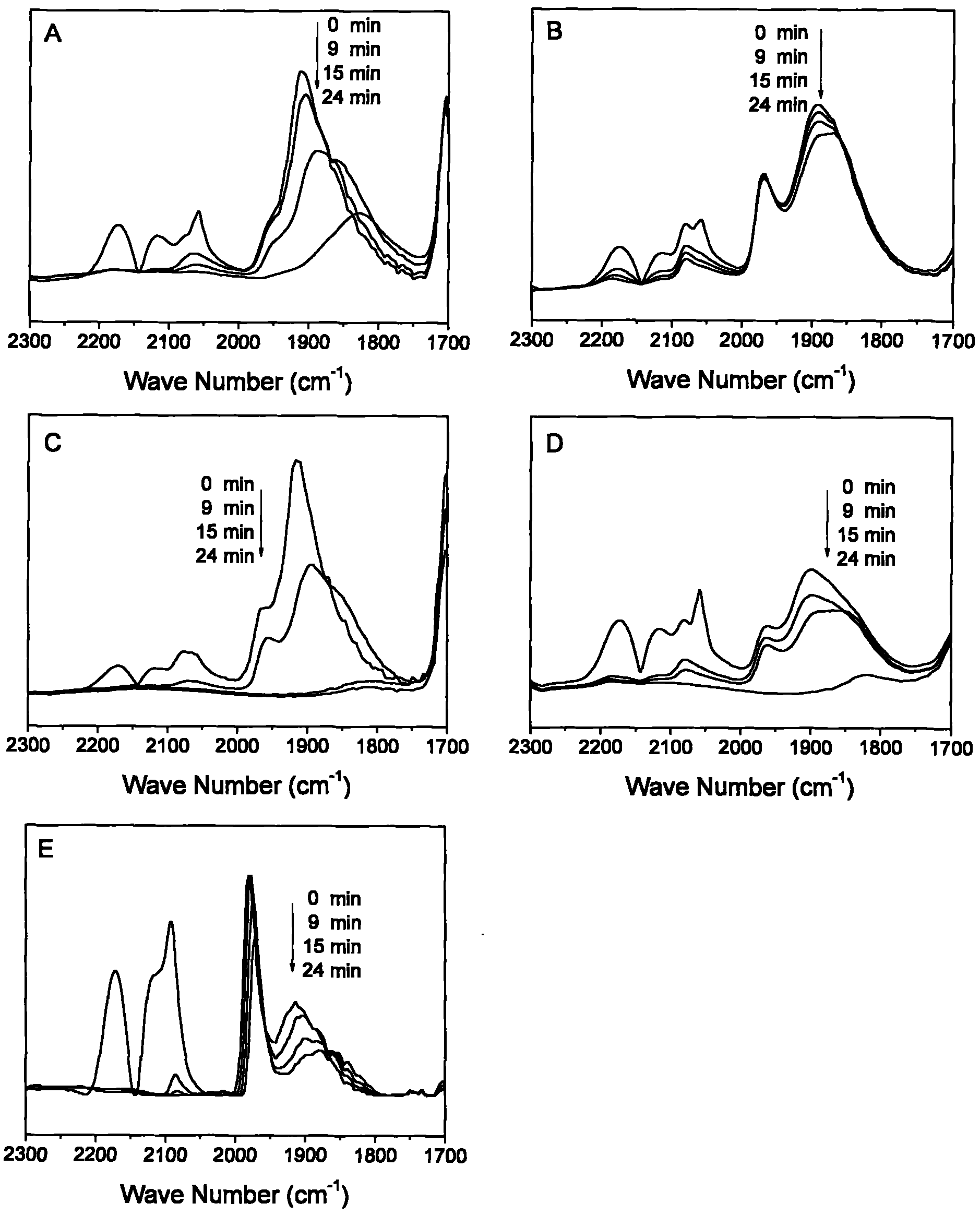

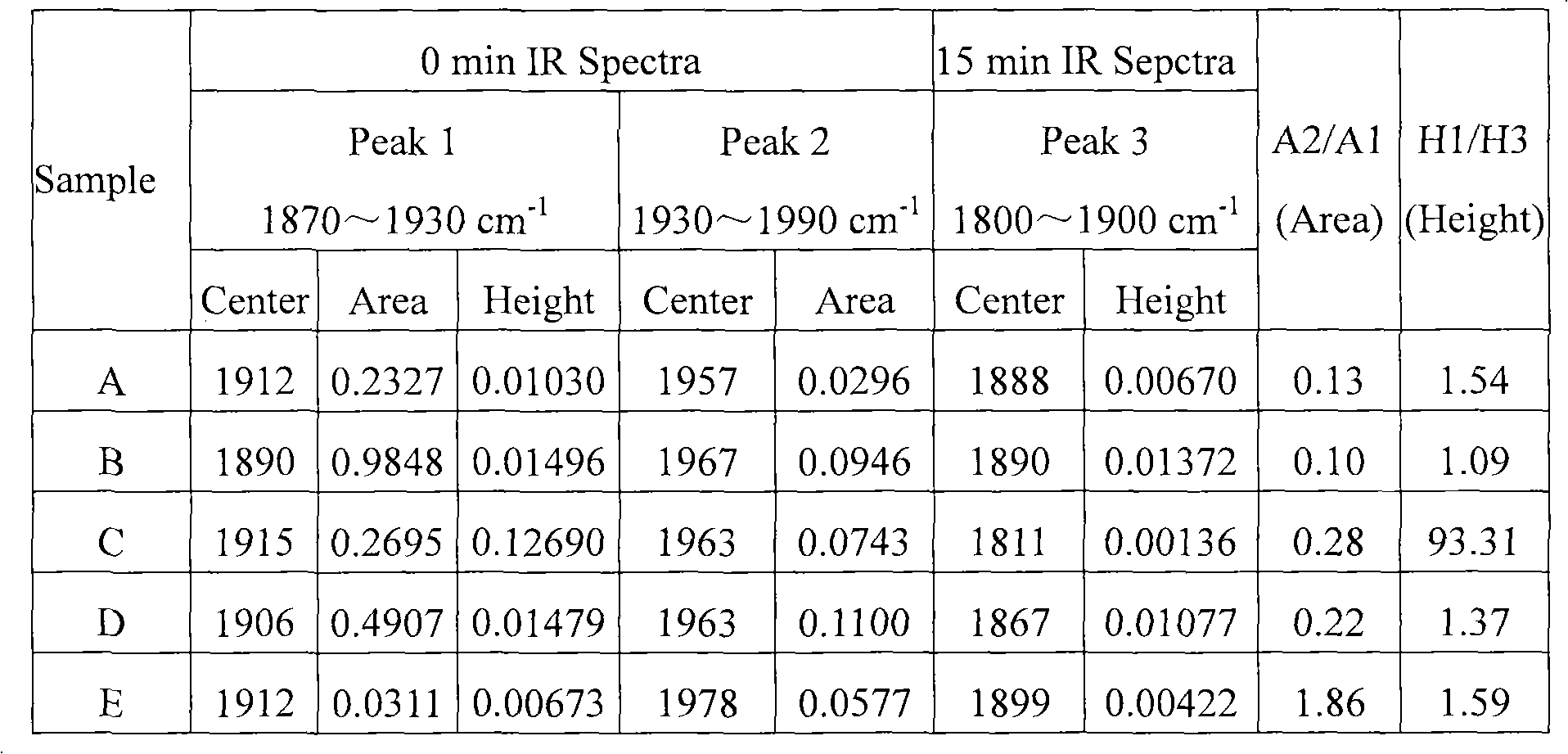

Image

Examples

Embodiment 1

[0040] Take 13.5ml of 10mg / ml PdCl 2 solution, dropwise add 1mol / L NaOH solution to adjust the pH to 5.6, then spray to 100.0g Al 2 O 3 Spherical carrier surface, use 20ml of 50% v / v isopropanol aqueous solution to wet the carrier and use it under vacuum 60 The Coγ radiation source was irradiated at room temperature for 15h, and the absorbed dose rate was 35Gy / min. After irradiation, the sample was placed in an oven, and dried at 80° C. and 120° C. for 12 hours in turn to obtain the catalyst A, which was gray-black in appearance and had a Pd content of 0.135 wt %.

Embodiment 2

[0042] Take 30ml of 10mg / ml PdCl 2 solution, sprayed to 100.0 g La and K modified Al 2 O 3 Tooth spherical carrier surface, then spray 5ml 1mol / L NaOH solution, use 20ml 50% v / v isopropanol aqueous solution to wet the carrier, and use it in a vacuum state 60 The Coγ radiation source was irradiated at room temperature for 15h, and the absorbed dose rate was 70Gy / min. After irradiation, the sample was placed in an oven, and dried at 80° C. and 120° C. for 12 hours in turn to obtain the catalyst B, which was gray in appearance and 0.300 wt % Pd content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com