Patents

Literature

73 results about "Carbon monoxide adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

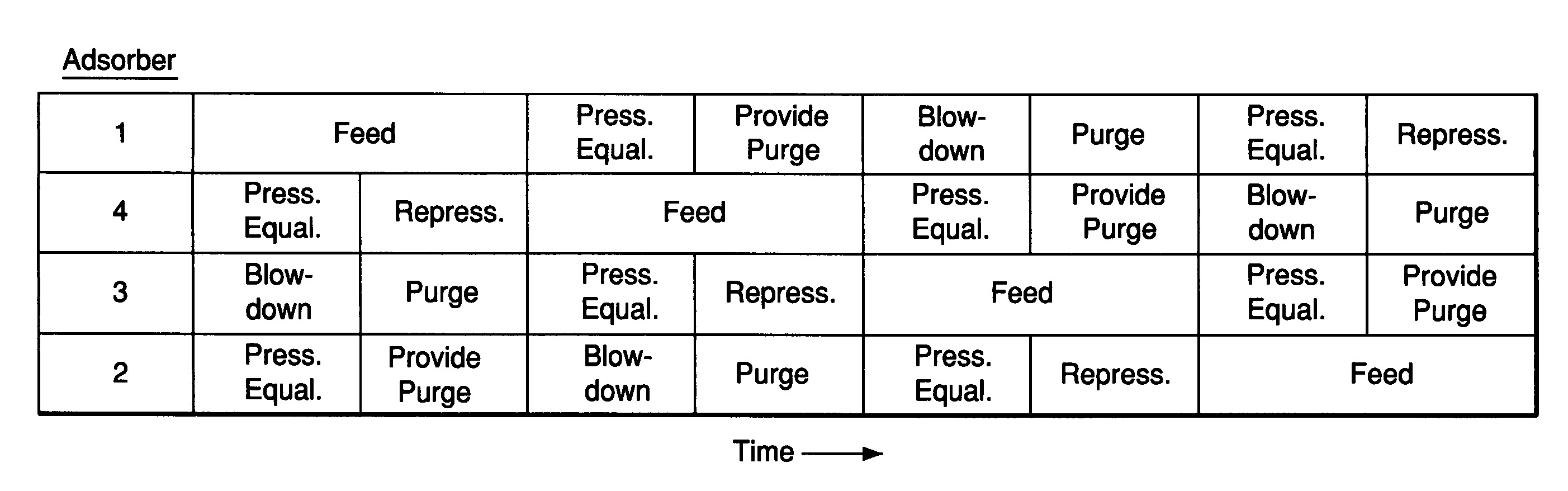

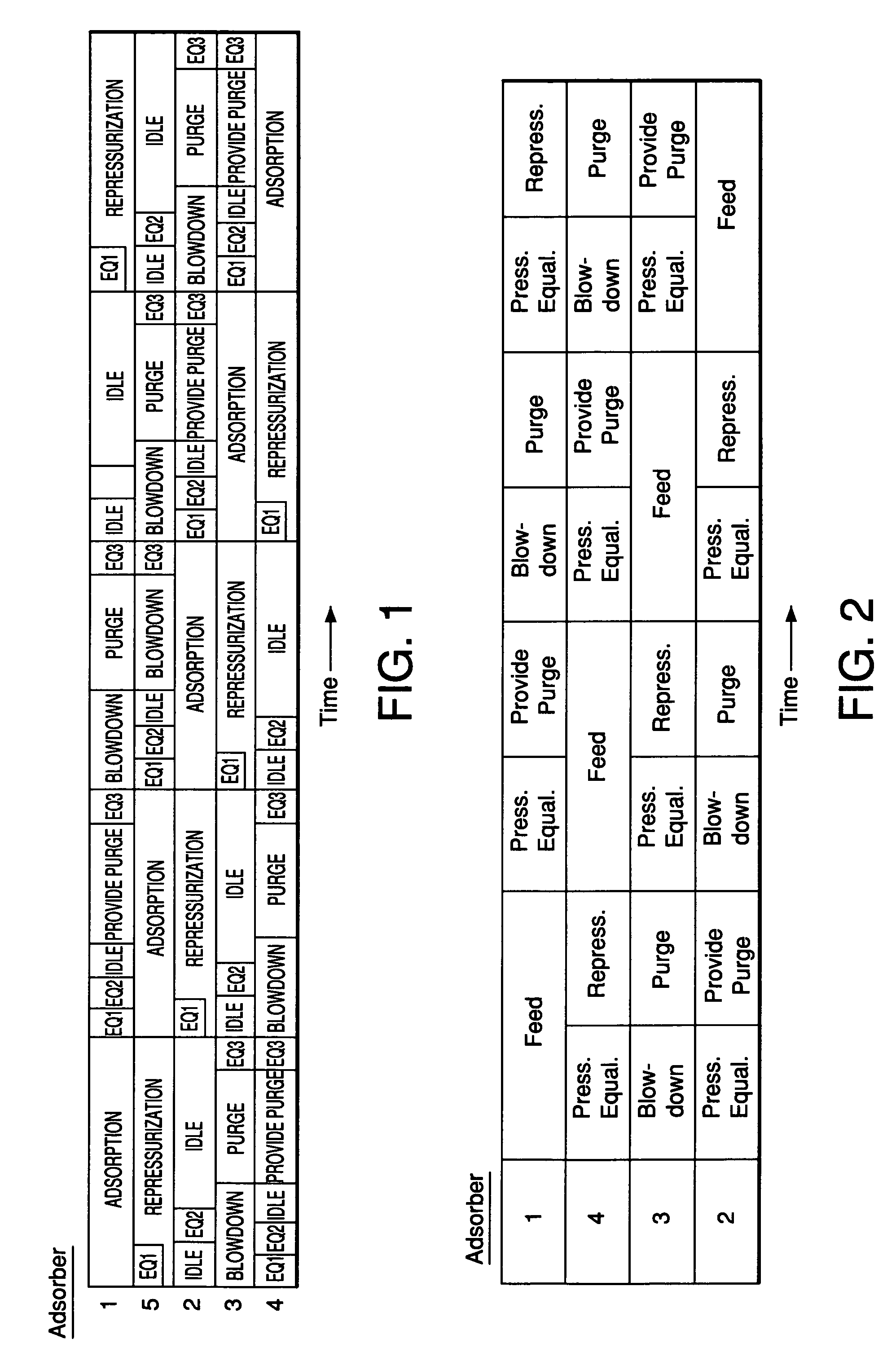

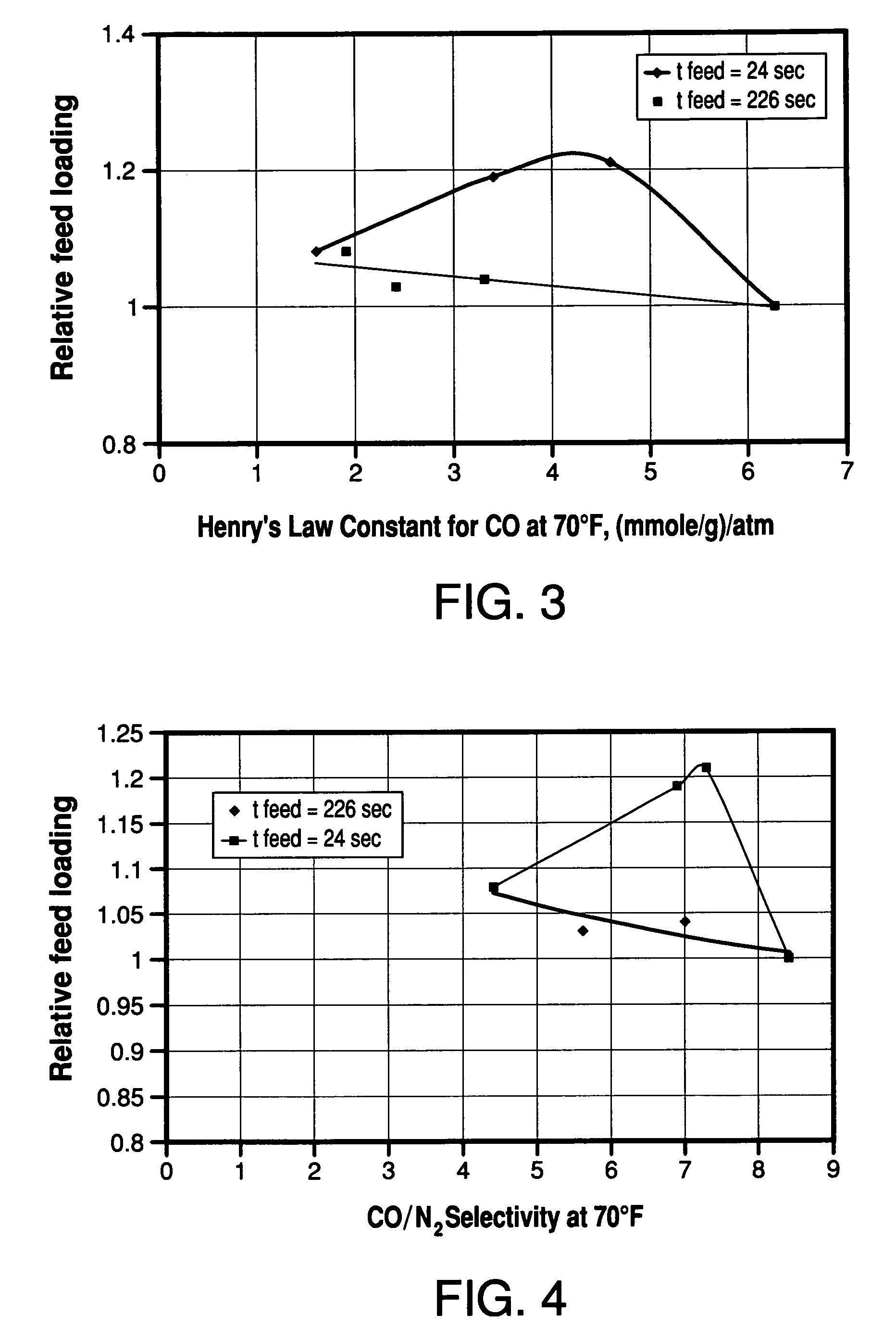

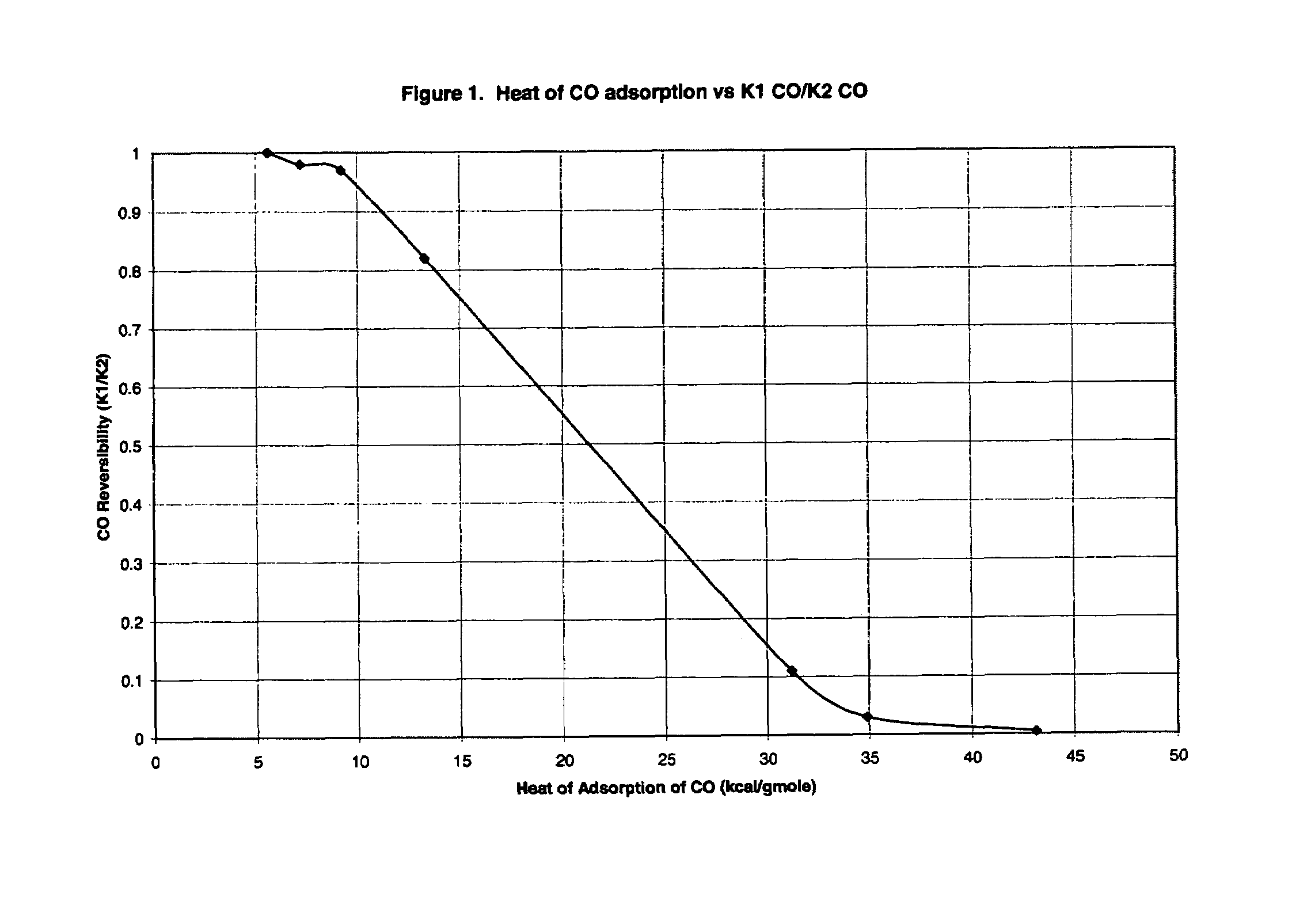

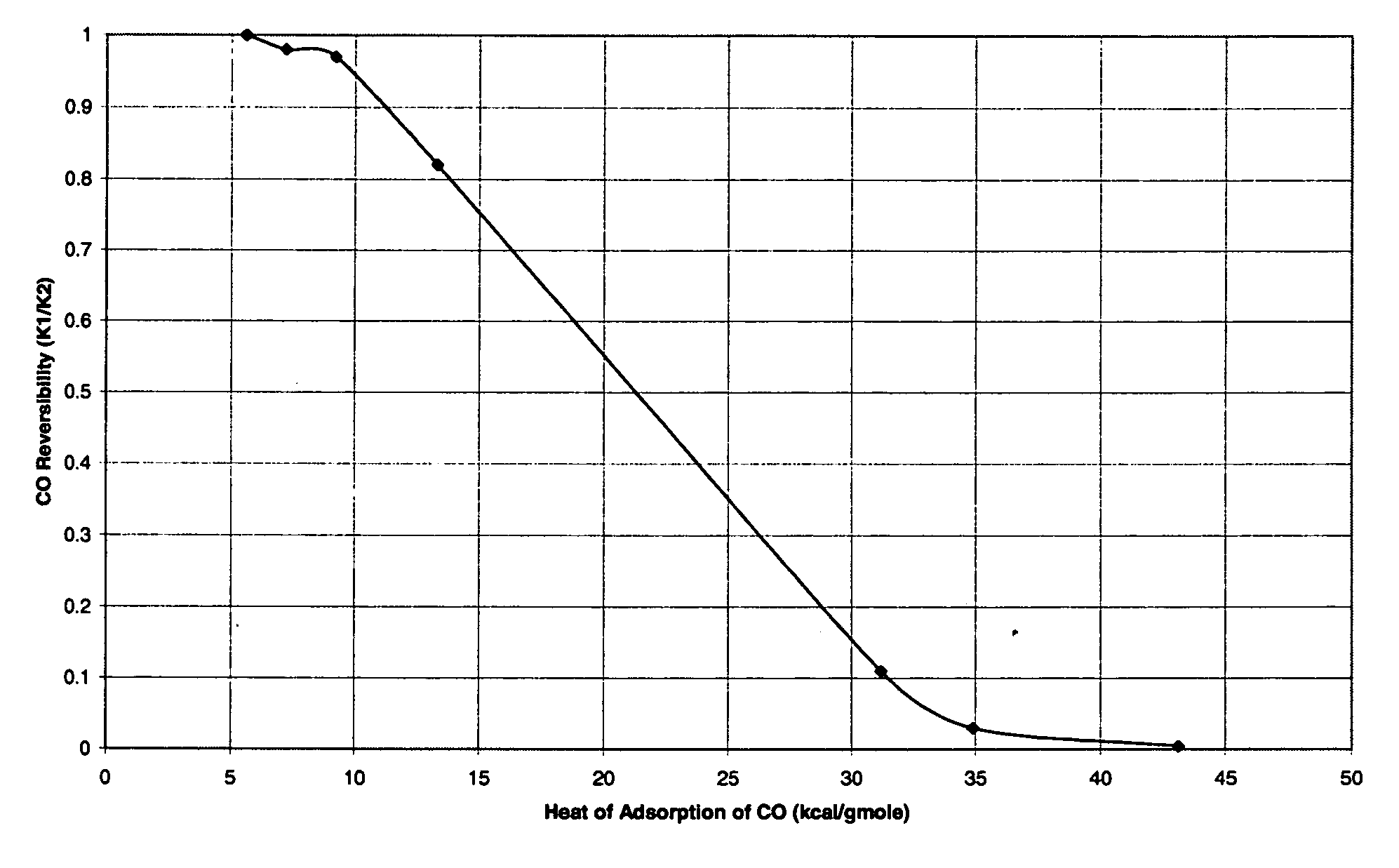

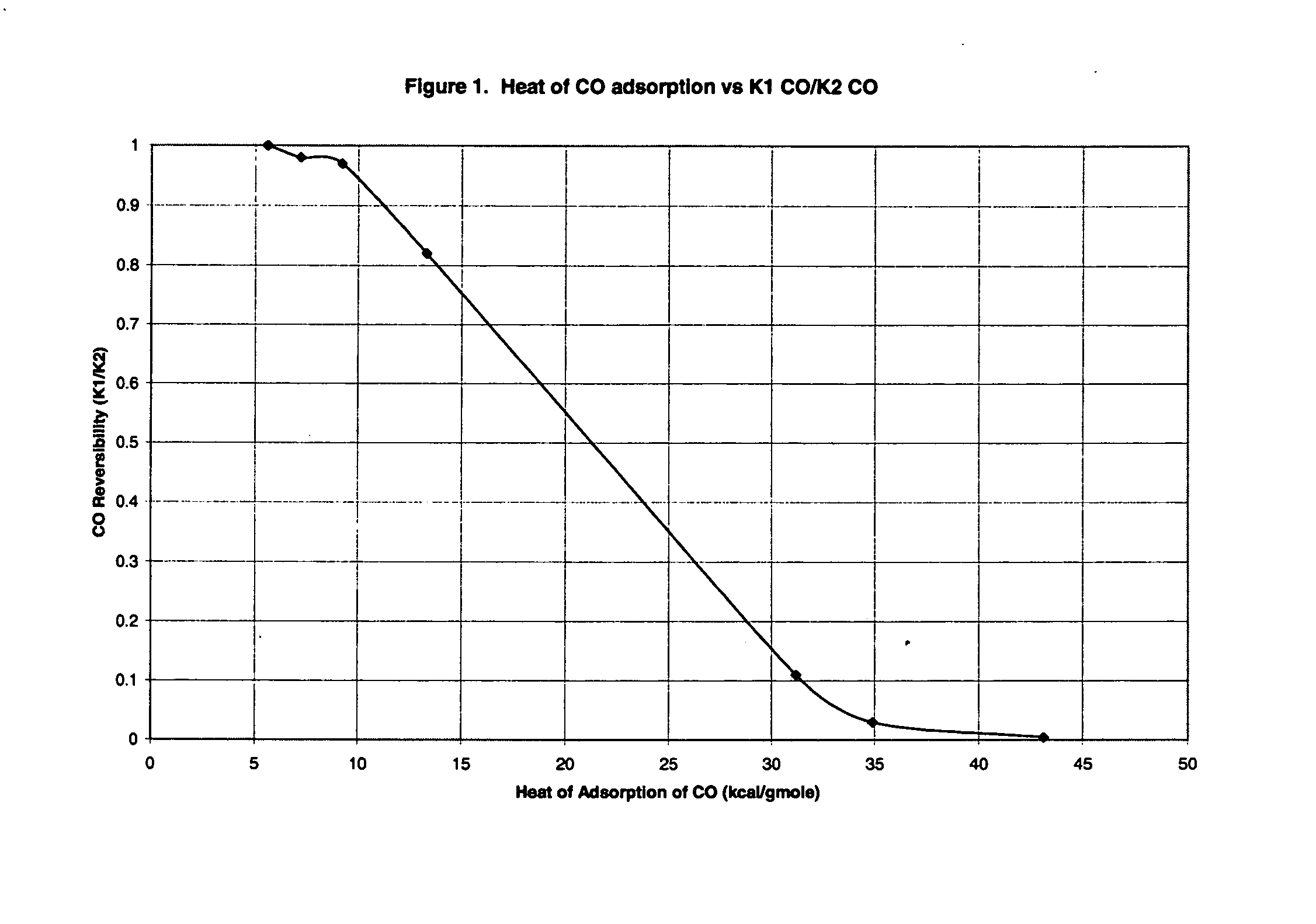

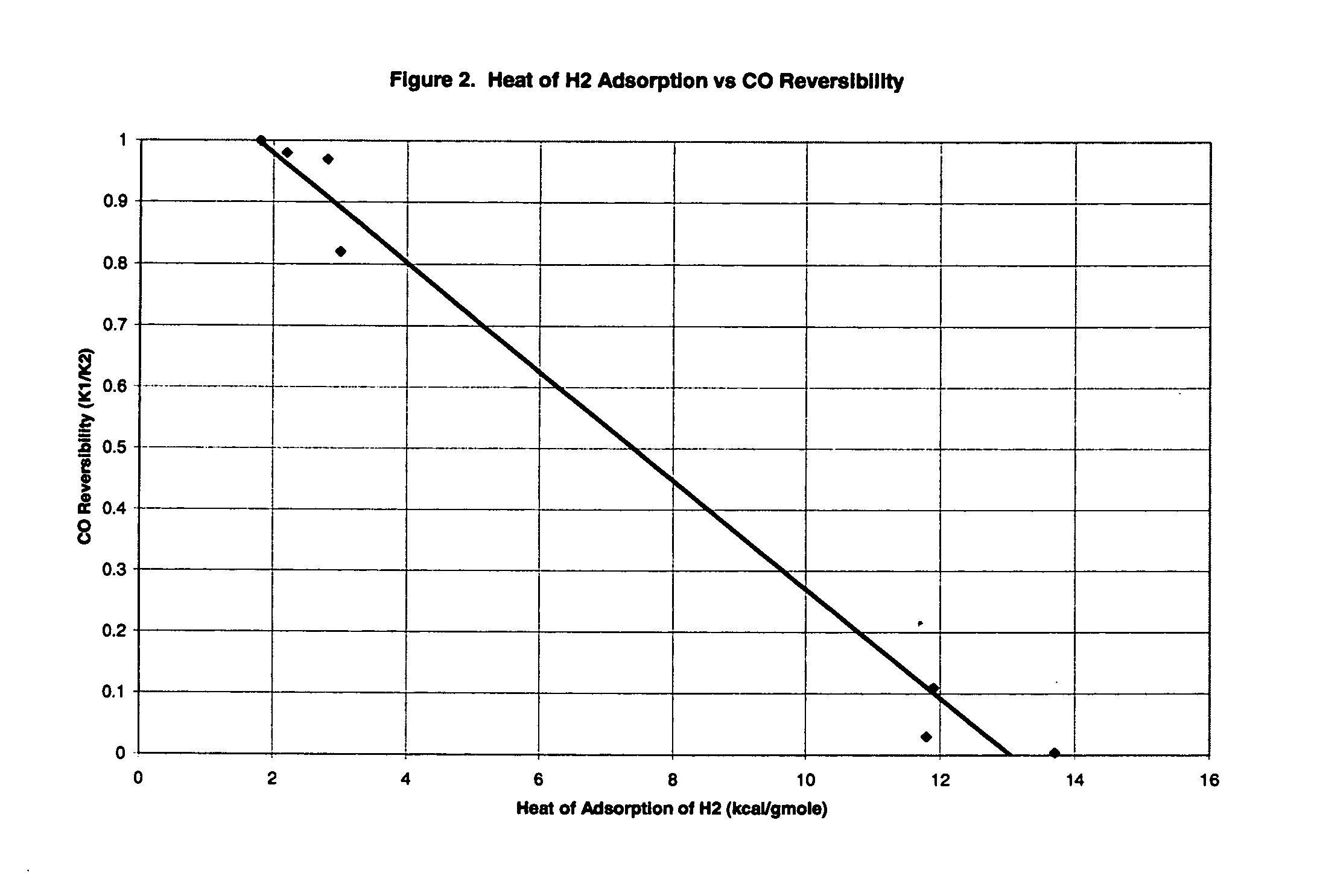

Adsorbents for rapid cycle pressure swing adsorption processes

Method for the separation of a gas mixture comprising providing a PSA system with at least one adsorber vessel containing adsorbent material that is selective for the adsorption of carbon monoxide and nitrogen, passing a feed gas mixture containing at least hydrogen and carbon monoxide and optionally containing nitrogen through the adsorbent material in a feed step and withdrawing a purified hydrogen product from the adsorber vessel, wherein the feed step has a duration or feed time period of about 30 seconds or less. The adsorbent material is characterized by any of (1) a Henry's law constant for carbon monoxide between about 2.5 and about 5.5 (mmole / g) / atm; (2) a carbon monoxide heat of adsorption between about 6.0 and about 7.5 kcal / gmole; (3) a Henry's law constant for nitrogen greater than about 1.5 (mmole / g) / atm; and (4) a selectivity of carbon monoxide to nitrogen between about 5.0 and about 8.0.

Owner:AIR PROD & CHEM INC

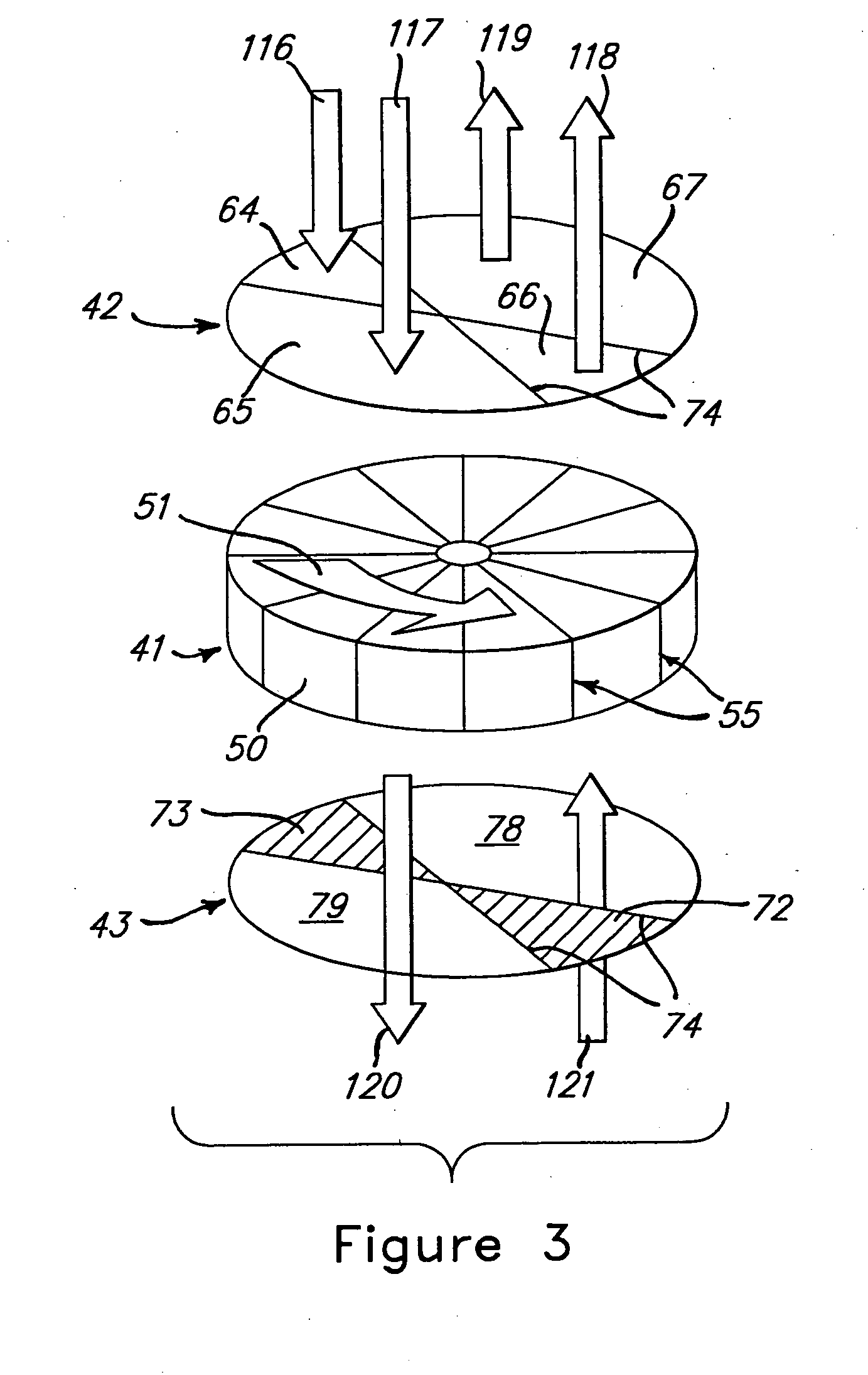

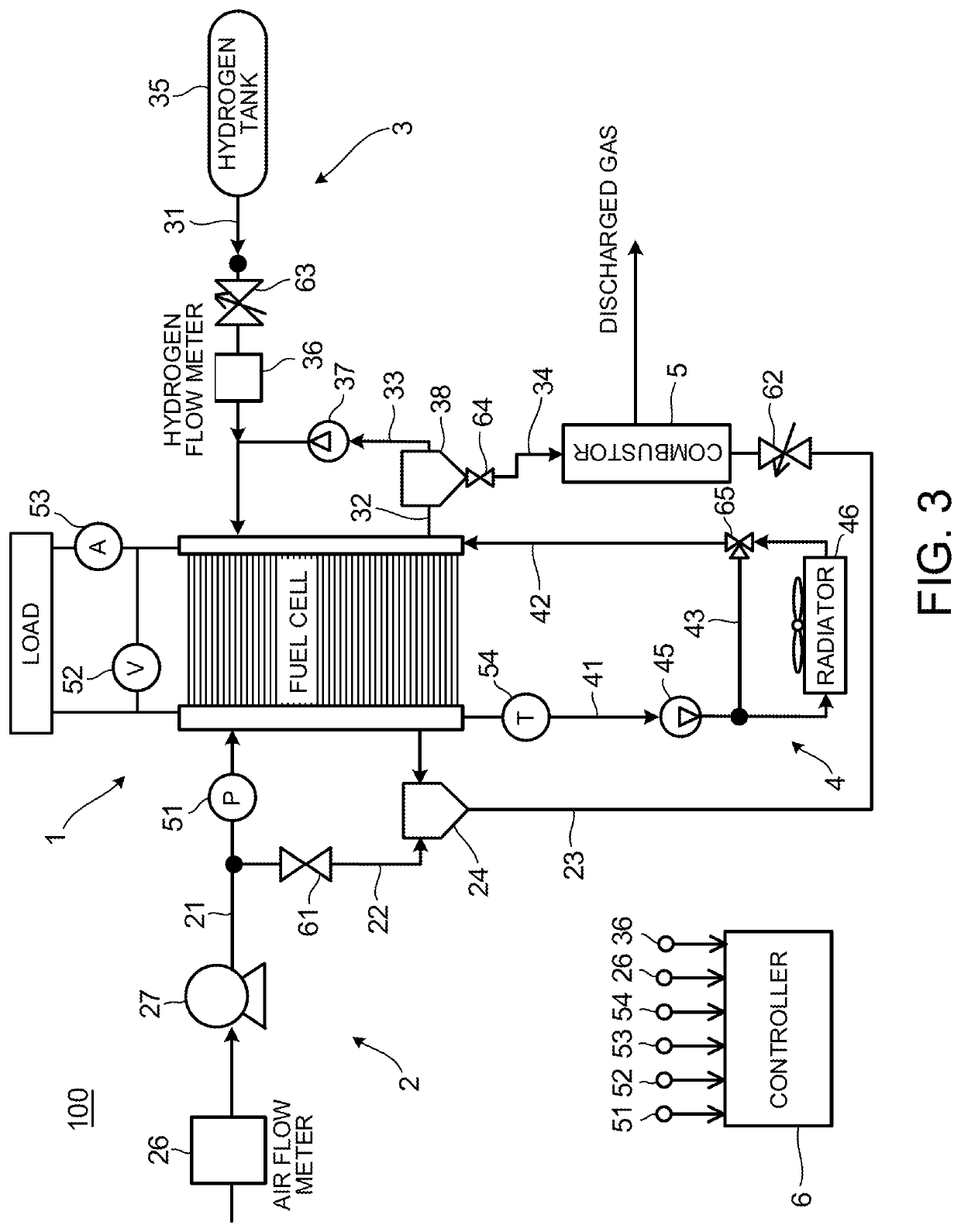

Carbon monoxide adsorption for carbon monoxide clean-up in a fuel cell system

InactiveUS6964692B2Eliminate useReduce carbon monoxide contentThermal non-catalytic crackingCombination devicesSorbentHydrogen fuel cell

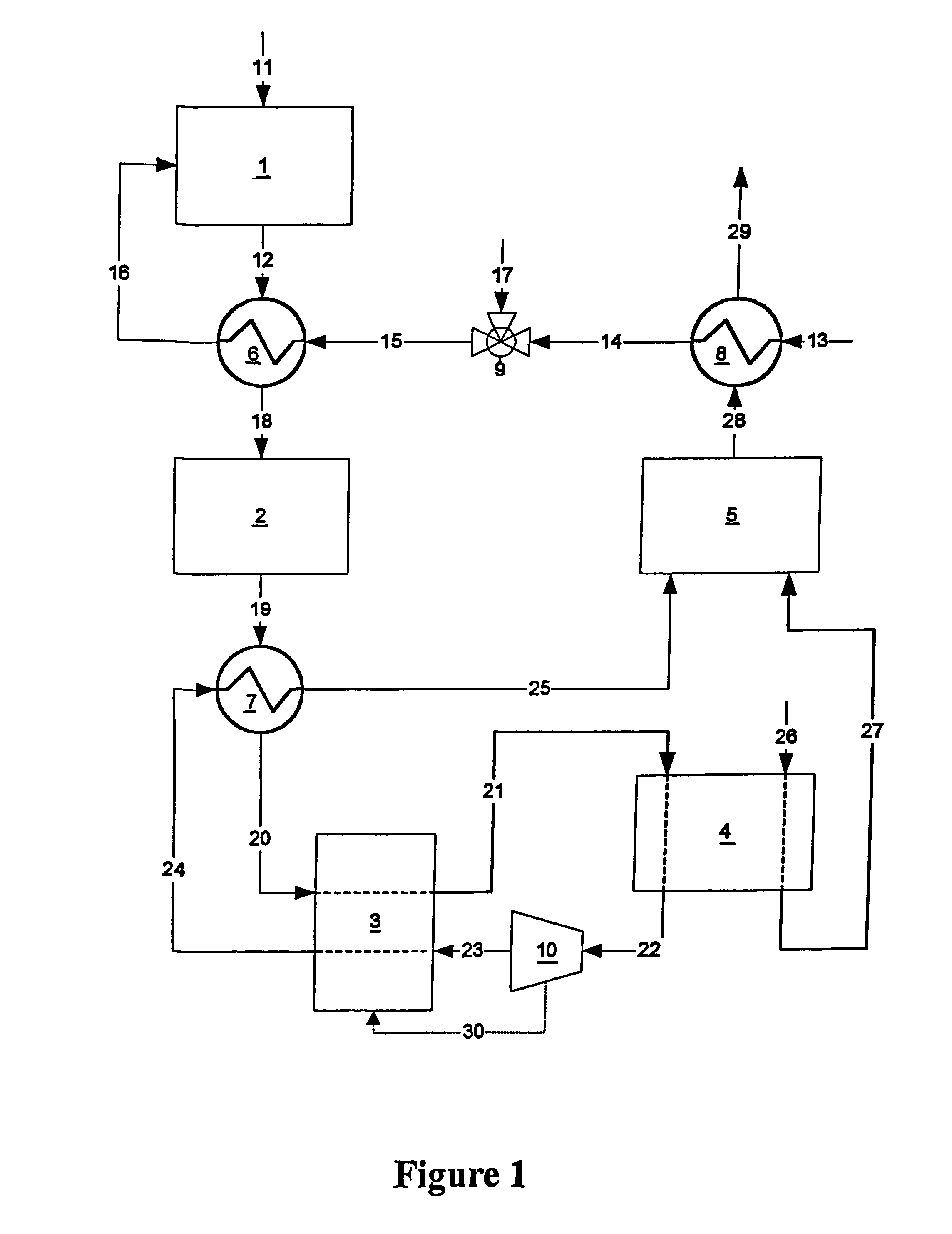

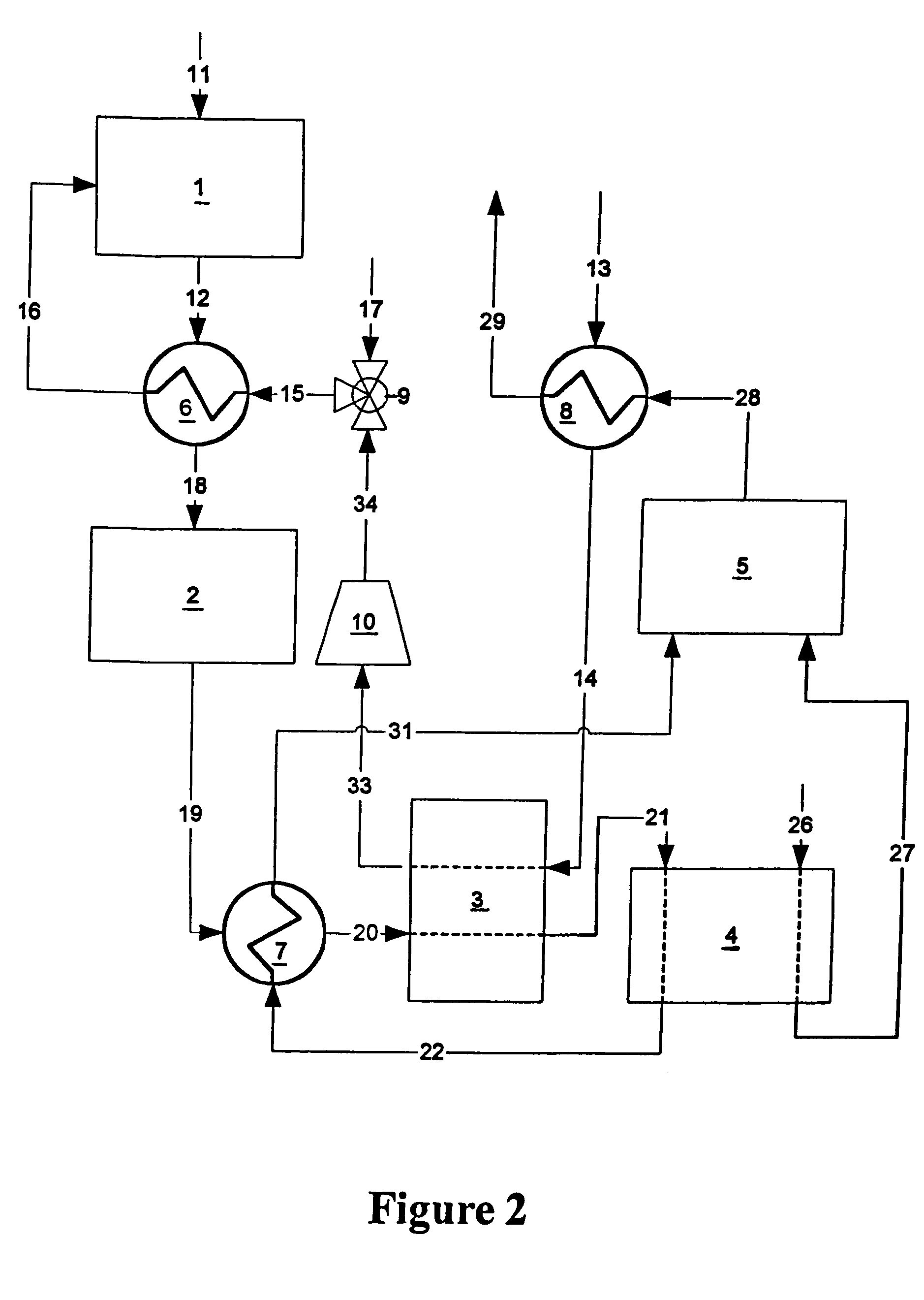

An apparatus removes carbon monoxide (CO) from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies of proton exchange membrane (PEM) fuel cells. A vessel houses a carbon monoxide adsorbent. The vessel may be a rotating pressure swing adsorber. A water gas shift reactor is upstream of the rotating pressure swing adsorber. The water gas shift reactor may include a second adsorbent adapted to adsorb carbon monoxide at low temperatures and to desorb carbon monoxide at high temperatures. The apparatus advantageously eliminates the use of a preferential oxidation (PROX) reactor, by providing an apparatus which incorporates CO adsorption in the place of the PROX reactor. This cleans up carbon monoxide without hydrogen consumption and the concomitant, undesirable excess low grade heat generation. The present invention reduces start-up duration, and improves overall fuel processor efficiency during normal operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

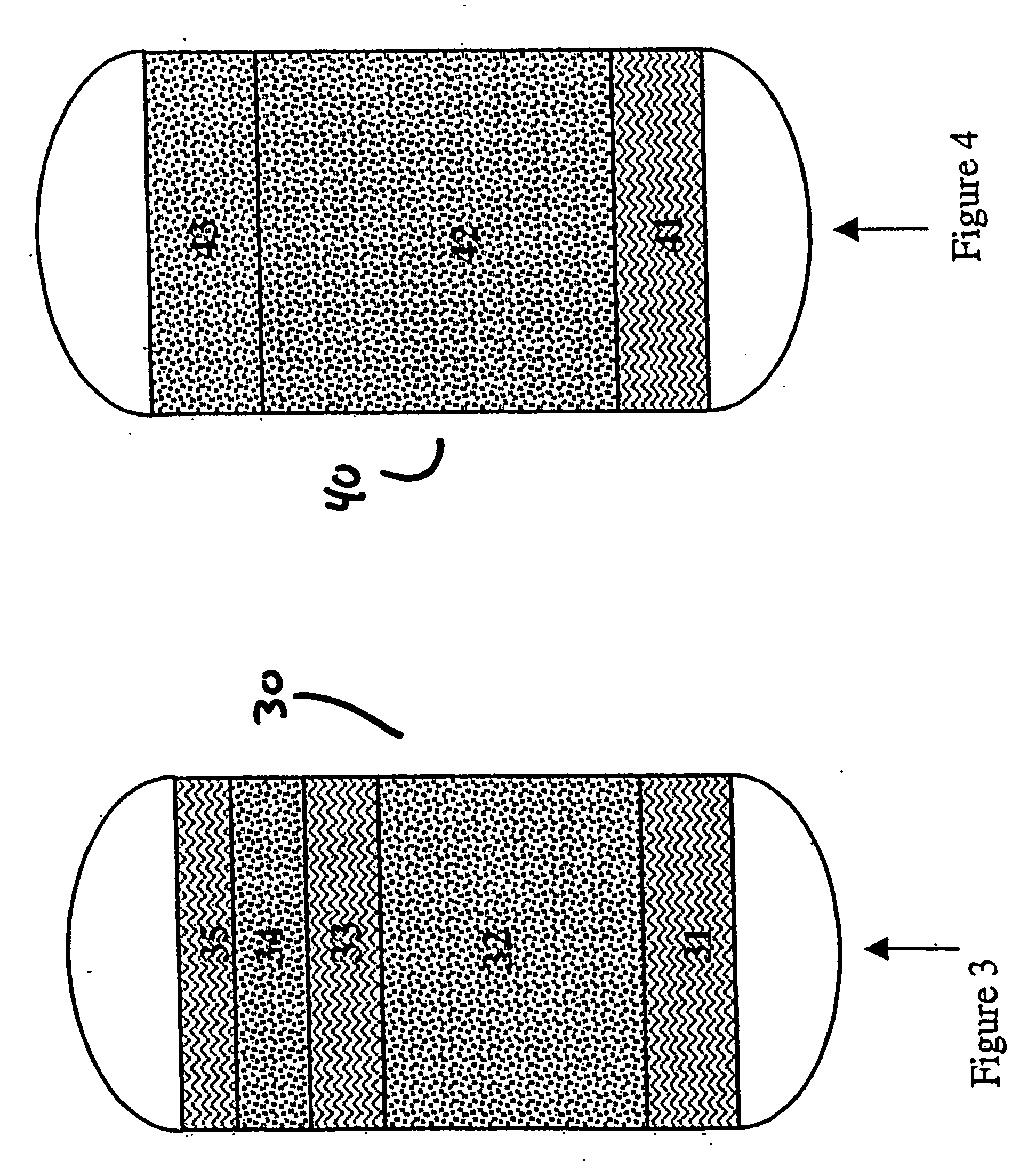

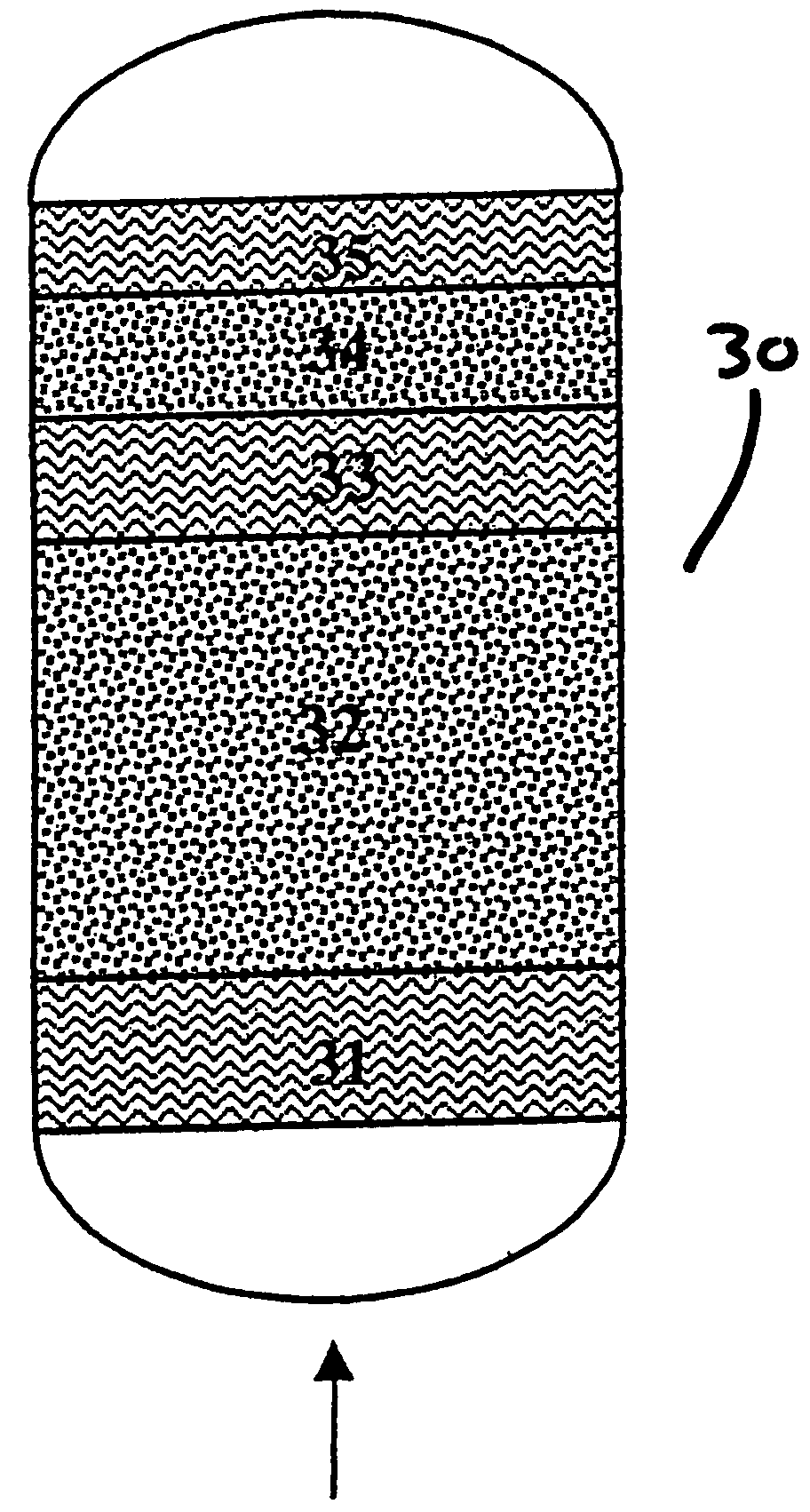

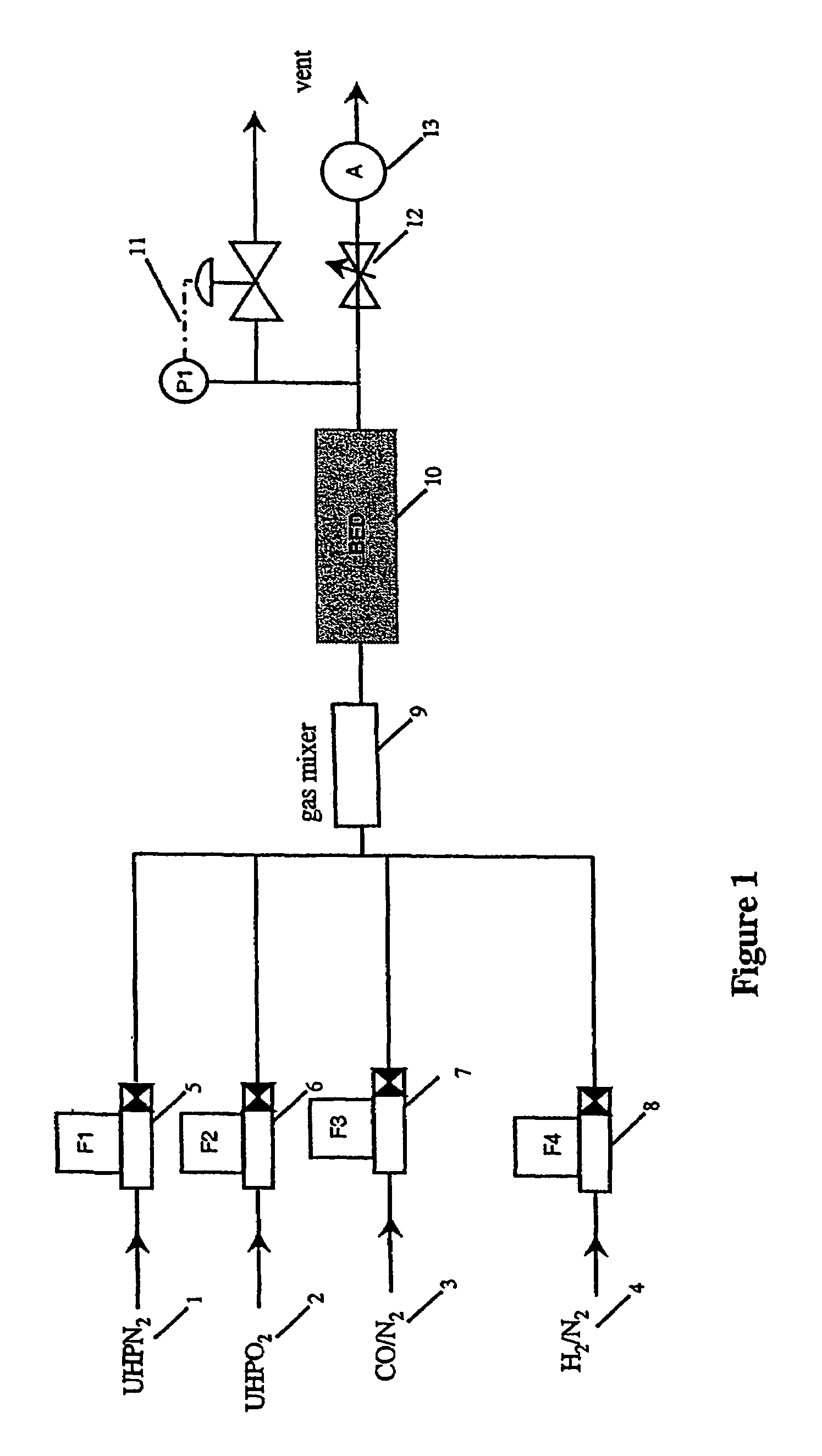

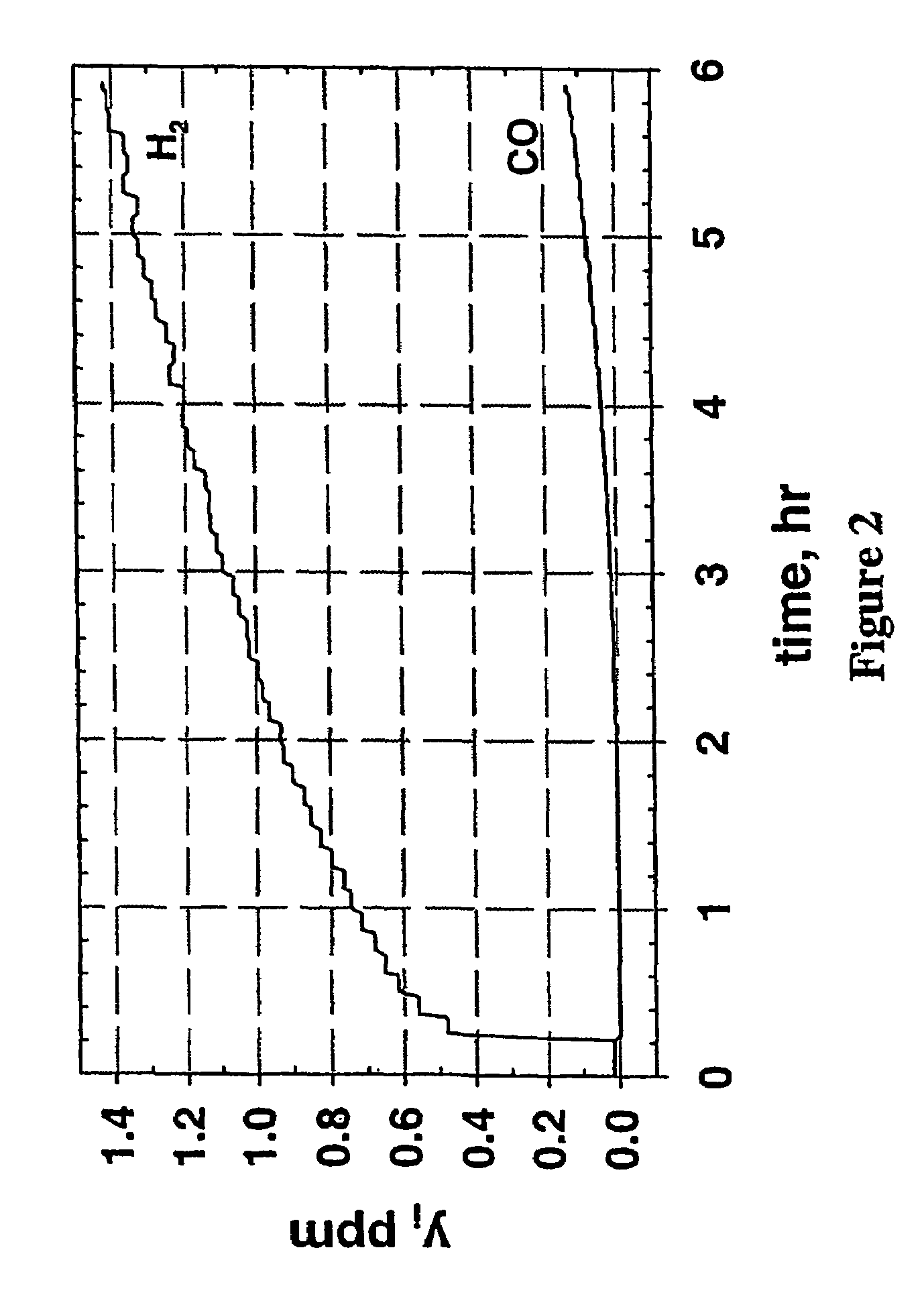

Production of high purity and ultra-high purity gas

InactiveUS20060210454A1Low costSuperior CO and H<subNitrous oxide captureCombination devicesHydrogenOperational costs

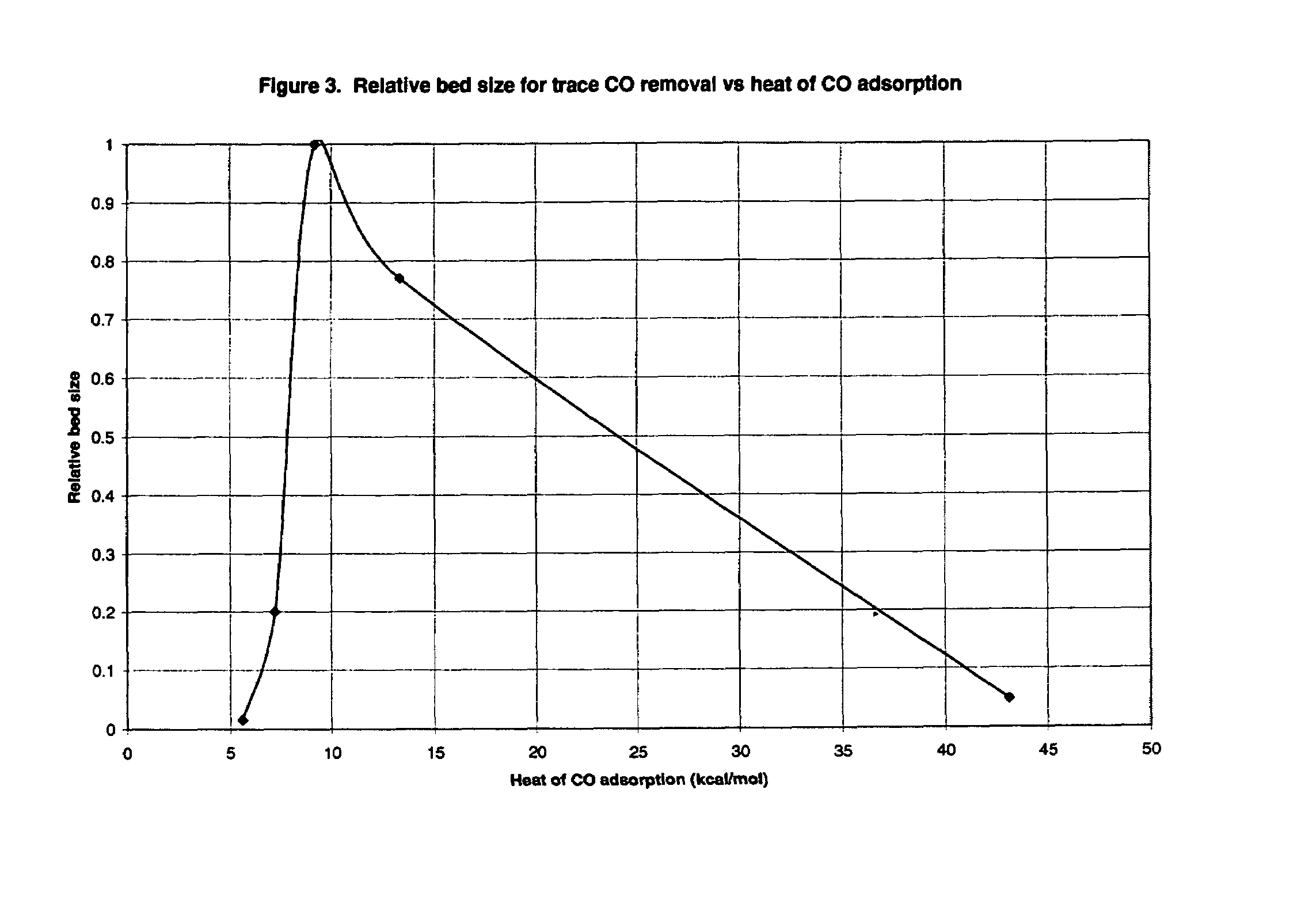

Trace amounts of carbon monoxide and optionally hydrogen are removed from gaseous feed streams by passing the feed stream through a carbon monoxide adsorbent (33) prior to passing it through a supported metal catalyst (34). The invention saves significant capital and operational costs over existing processes.

Owner:PRAXAIR TECH INC

Production of high purity and ultra-high purity gas

InactiveUS7524358B2Low costSuperior CO and H<subNitrous oxide captureCombination devicesOperational costsHydrogen

Trace amounts of carbon monoxide and optionally hydrogen are removed from gaseous feed streams by passing the feed stream through a carbon monoxide adsorbent (33) prior to passing it through a supported metal catalyst (34). The invention saves significant capital and operational costs over existing processes.

Owner:PRAXAIR TECH INC

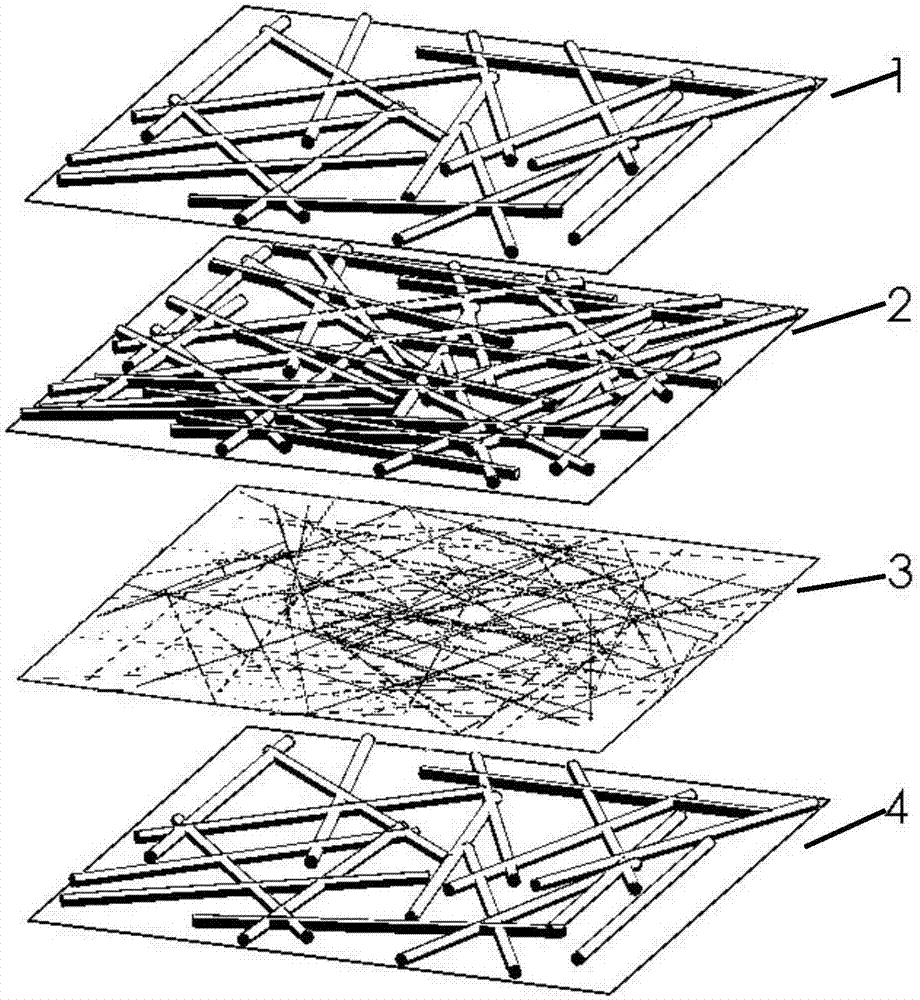

Nano-fiber and micro-fiber composite anti-haze gauze mask

InactiveCN107455822ASmall air resistanceEasy to prepareProtective garmentSpecial outerwear garmentsParticulatesNitric oxide

The invention relates to a nano-fiber and micro-fiber composite anti-haze gauze mask. The gauze mask has the advantages that the air resistance is low, and the particulate pollutant filtering efficiency is high; the gauze mask can filter volatile organic compounds, acid gas, alkaline gas, nitric oxides, sulfur oxides and carbon monoxide, or eliminate smoke, peculiar smell, formaldehyde and the like, and can be used for prevention in various pollution-gase sites. The nano-fiber and micro-fiber composite anti-haze gauze mask includes at least one micro-fiber layer and a nano fiber layer, wherein the nano fiber layer is arranged on the inner side of the micro-fiber layer and can filter volatile organic compounds, acid gas, alkaline gas, nitric oxides, sulfur oxides and carbon monoxide and eliminate smoke, peculiar smell and formaldehyde; functional additives are added into nano fibers of the nano fiber layer and include a VOC adsorbent, an aidic adsorbent, an alkaline adsorbent, a bactericide, an antiviral agent, a photolysis catalyst used for decomposing VOC, a formaldehyde catalytic oxidant and a carbon monoxide adsorbent.

Owner:江苏纳纤新材料科技有限公司

Method for preparing molecular sieve absorbent with high adsorption capacity

The invention relates to a method for preparing the absorber of molecule screen, wherein it is characterized in that: it improves the calcium content to prepare the absorber with high adsorption on nitrogen, carbon oxide, oxygen, water, etc. And said method mixes 4A molecule screen with calcium compound, uses caoline as adhesive, compresses, bakes, treats with alkali, exchanges with calcii chloridum solution and activates. The nitrogen adsorption of product can reach 11.5ml / g, and the carbon oxide adsorption can reach 34ml / g, and the skellysolve B adsorption can reach 16%.

Owner:TAIYUAN UNIV OF TECH

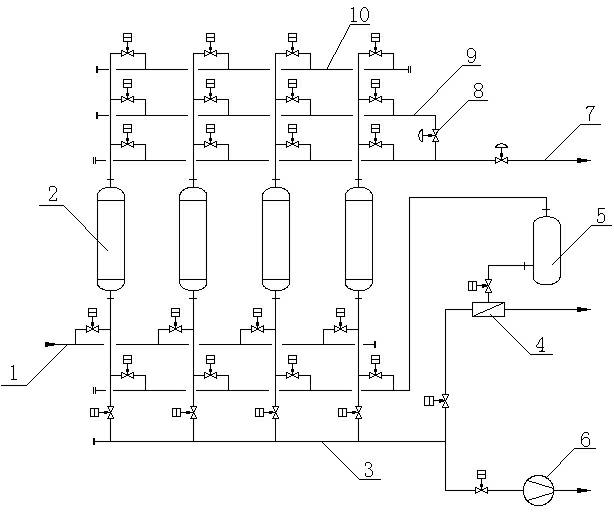

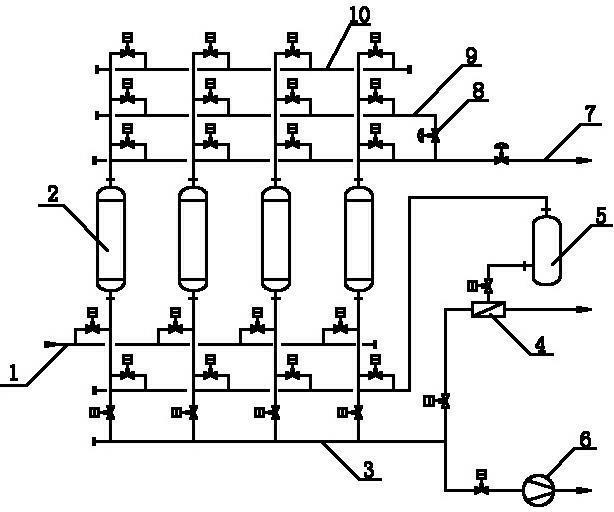

One-stage hydrogen separating and purifying method based on pressure swing adsorption membrane and device for realizing same

ActiveCN102674249ASmall scaleLarge amount of processingHydrogen separation using solid contactSorbentBuffer tank

The invention discloses a one-stage hydrogen separating and purifying method based on a pressure swing adsorption membrane and a device for realizing the same. The method comprises the following steps of: a, adsorption, wherein feed gas with hydrogen content of 75%, carbon dioxide content of 24.5%, carbon monoxide content of 0.5% and pressure of 1.2Mpa is fed into an adsorption tower, a hydrogen purification adsorbent filled in the adsorption tower adsorbs the carbon dioxide and the carbon monoxide in the feed gas, effective gas component hydrogen is output from the top of the adsorption tower, and the product hydrogen is sent to a user from the device through an outlet valve; and b, regeneration, wherein after the feed gas is adsorbed in the adsorption tower, equalized pressure drop and inverse discharge are performed on the adsorption tower, inversely discharged gas enters into a membrane separation unit, infiltration gas is stored in a buffer tank and then returned into the evacuated adsorption tower, and finally equalized pressure increasing and final charge are performed on the adsorption tower. By utilizing the process, the size of a pressure swing adsorption device can be reduced, the hydrogen yield is improved, and the cost is lowered.

Owner:SICHUAN TECHAIRS

Production of carbon monoxide-free hydrogen and helium from a high-purity source

Owner:AIR PROD & CHEM INC

Preparation method of special high-performance 5A molecular sieve for pressure swing adsorption

ActiveCN101890332AImprove adsorption capacityAvoid emissionsOther chemical processesDispersed particle separationDesorptionKaolin clay

The invention relates to a preparation method of a special high-performance 5A molecular sieve for pressure swing adsorption, which comprises the following steps of: mixing and granulating 4A molecular sieve raw powder and kaolin clay, drying, calcining, washing with alkali and transforming crystals, exchanging, activating, packaging and the like. The invention has the characteristics that saturated lime water is used for exchanging, thereby avoiding the problem of difficult wastewater processing caused by high content of wastewater chloride ions when calcium chloride is used for exchanging in traditional production. The 5A molecular sieve of the invention has large adsorption capacity, high adsorption and desorption speed and high mechanical strength, the nitrogen adsorption capacity is larger than 15ml / g, the nitrogen-oxygen adsorption ratio is larger than 3.2, the carbon monoxide adsorption capacity is larger than 30ml / g, and the compression strength is larger than 50N. The product is used for pressure swing adsorption and oxygen production, the purification of hydrogen gas and carbon monoxide and the dewaxing of petroleum refineries.

Owner:都江堰清天新材料技术有限责任公司

Selective hydrogenation method of alkyne and alkadiene in C4 hydrocarbon material flow

ActiveCN102249835AGuaranteed reaction selectivityGuaranteed reactivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPalladium catalystAlkyne

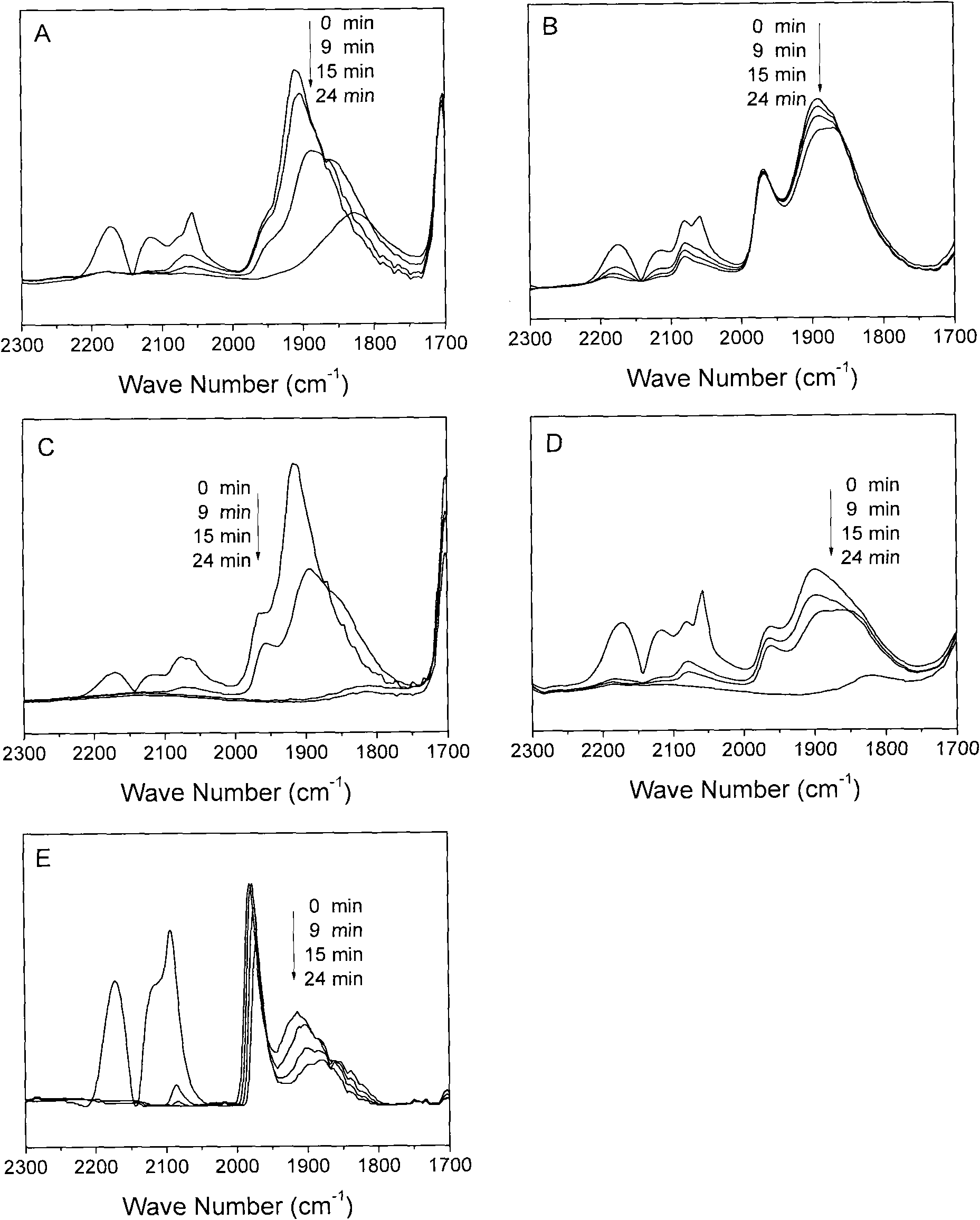

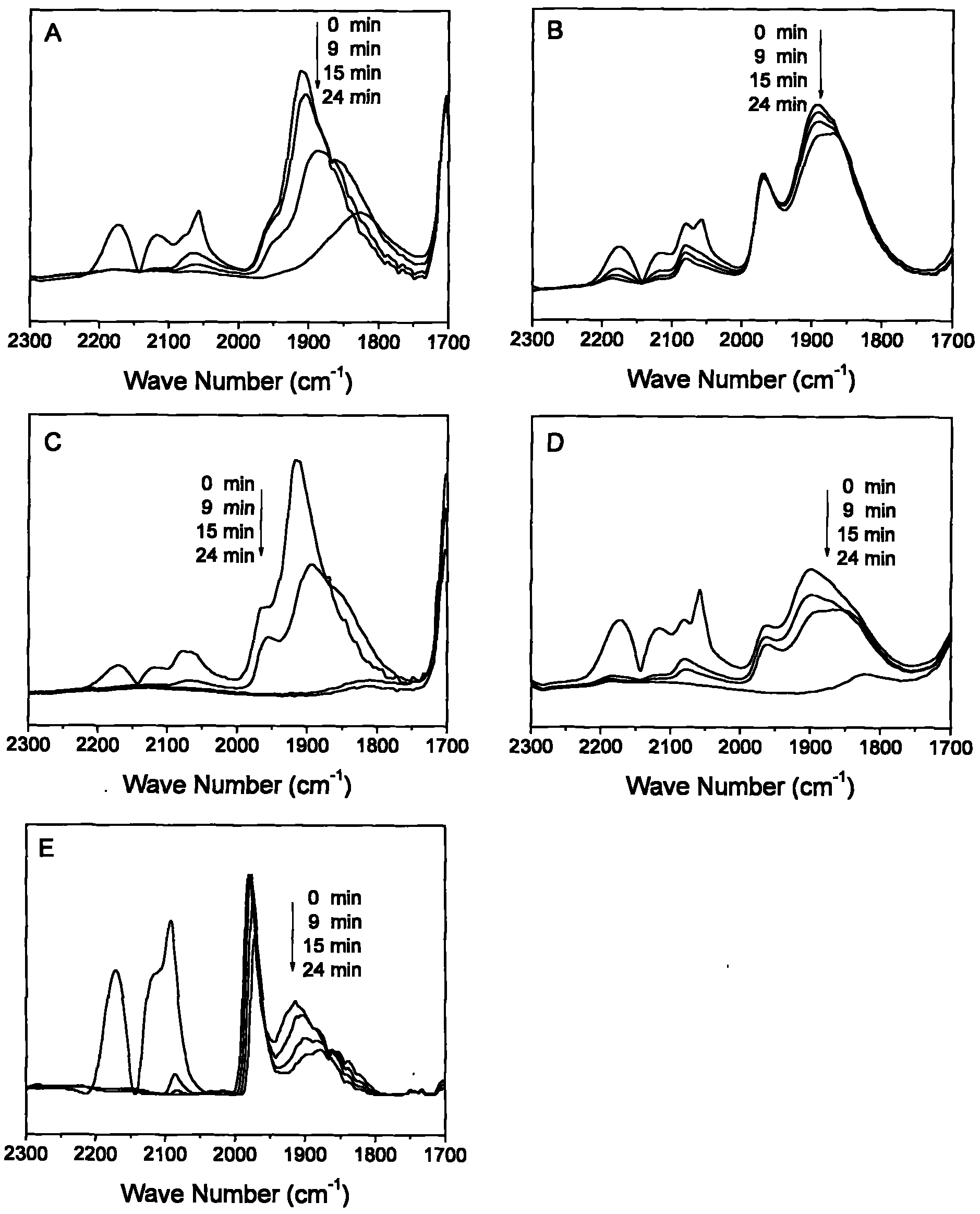

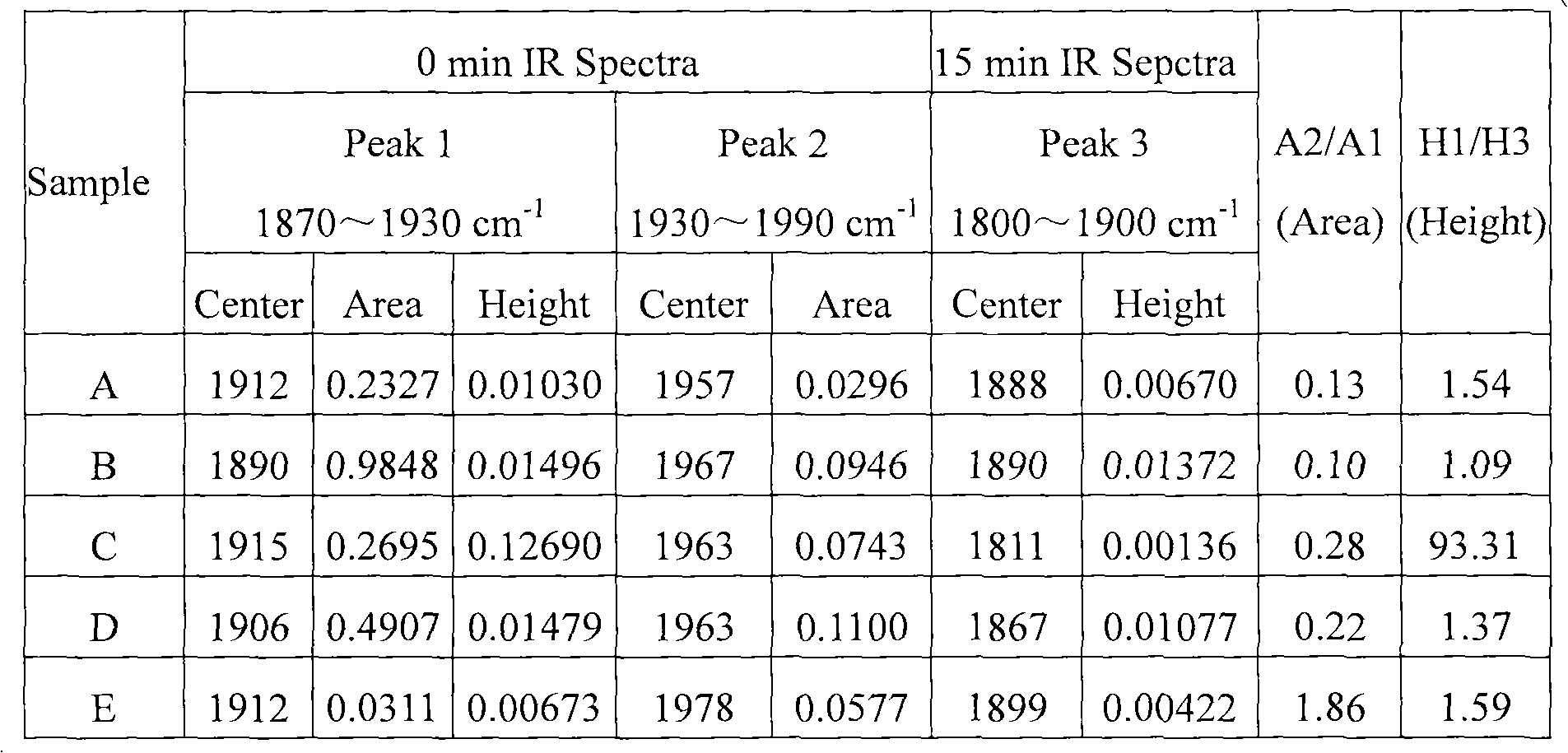

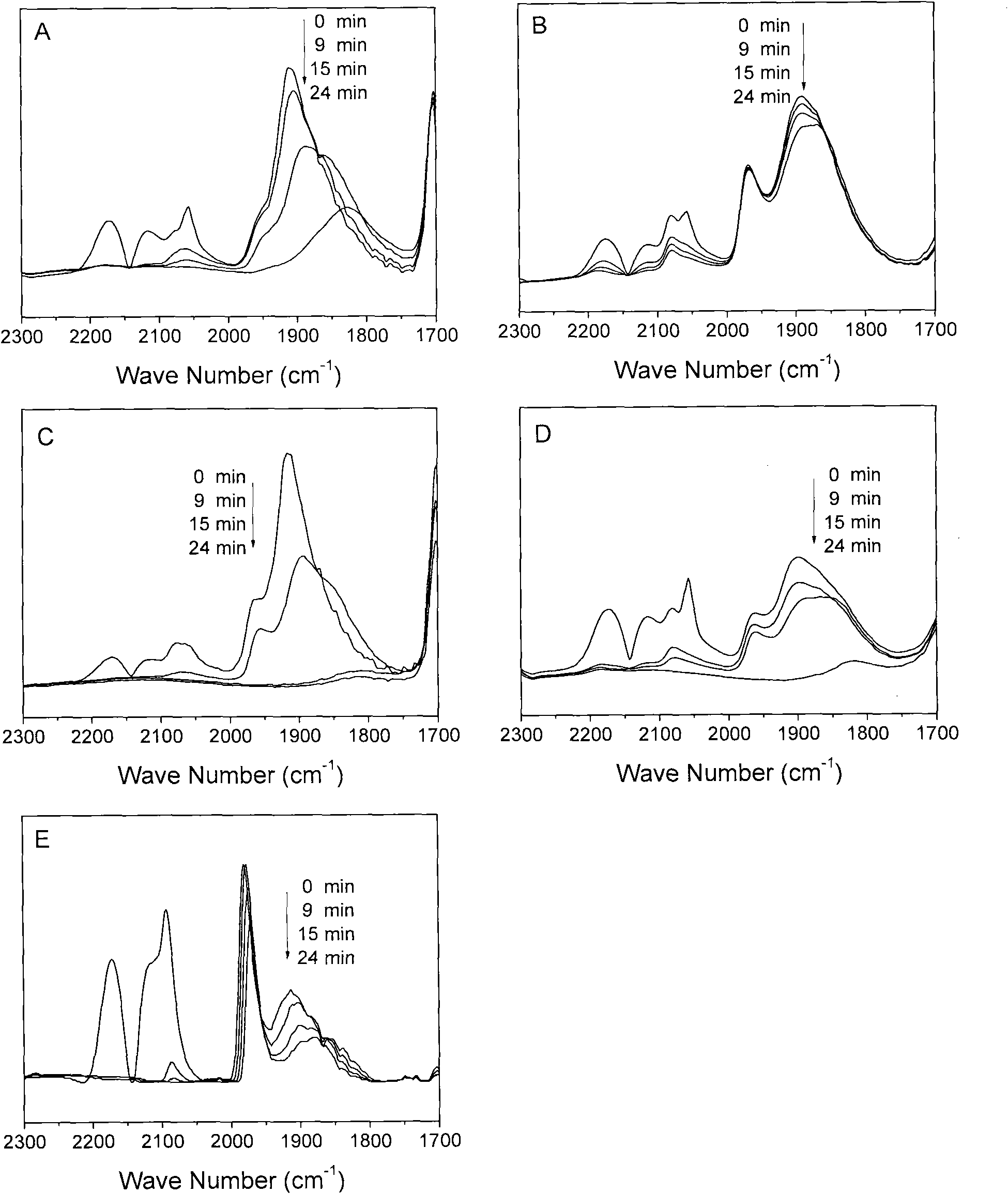

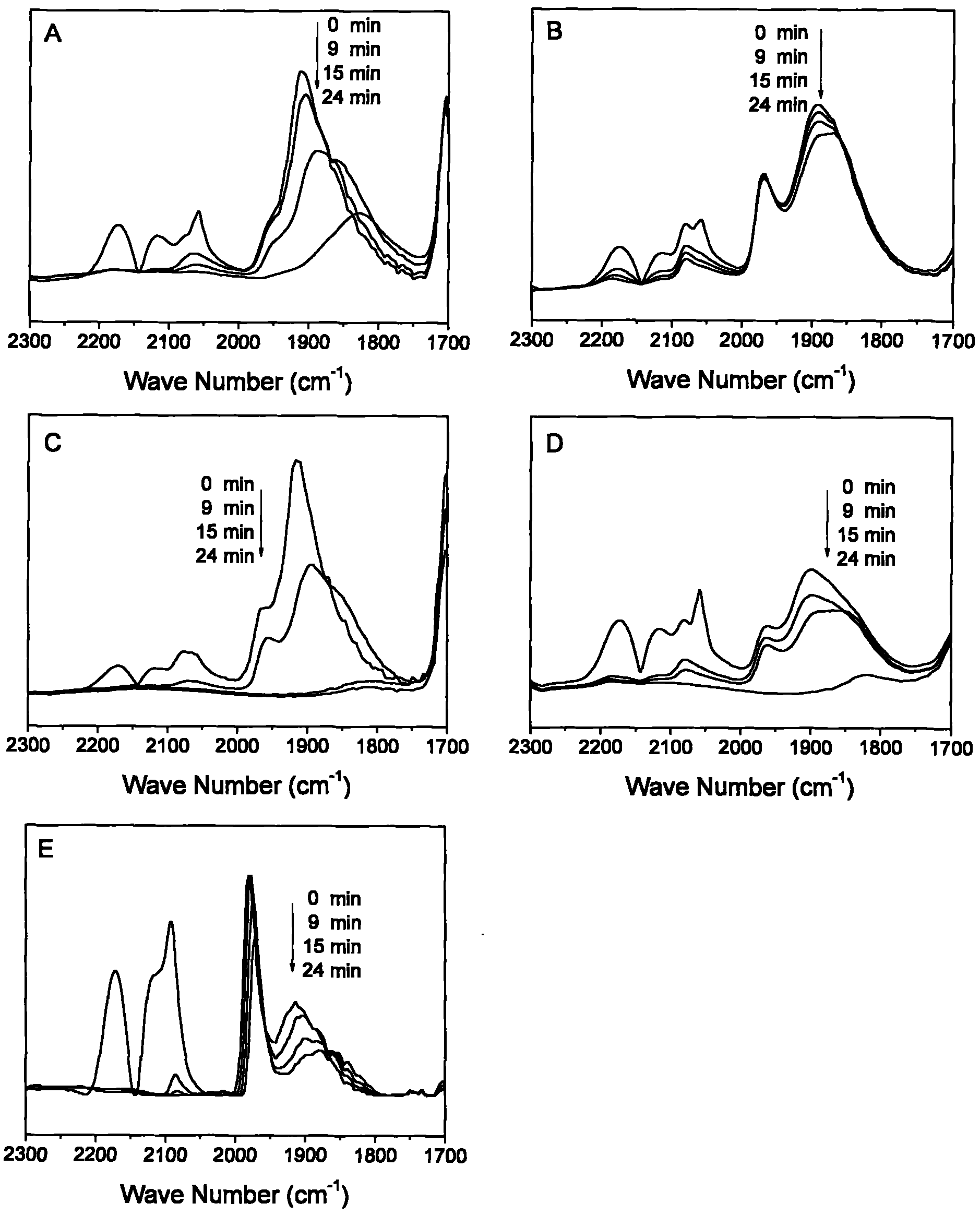

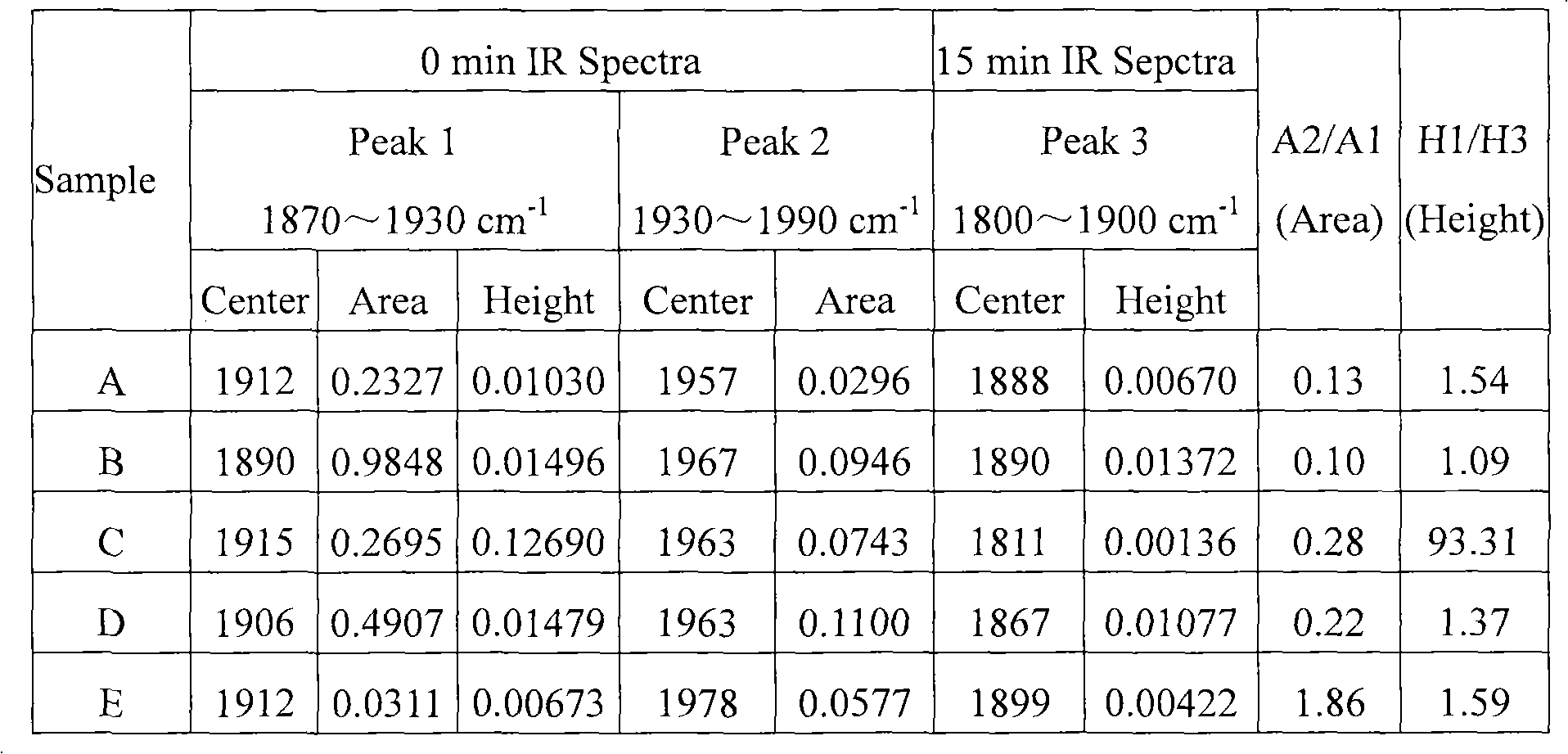

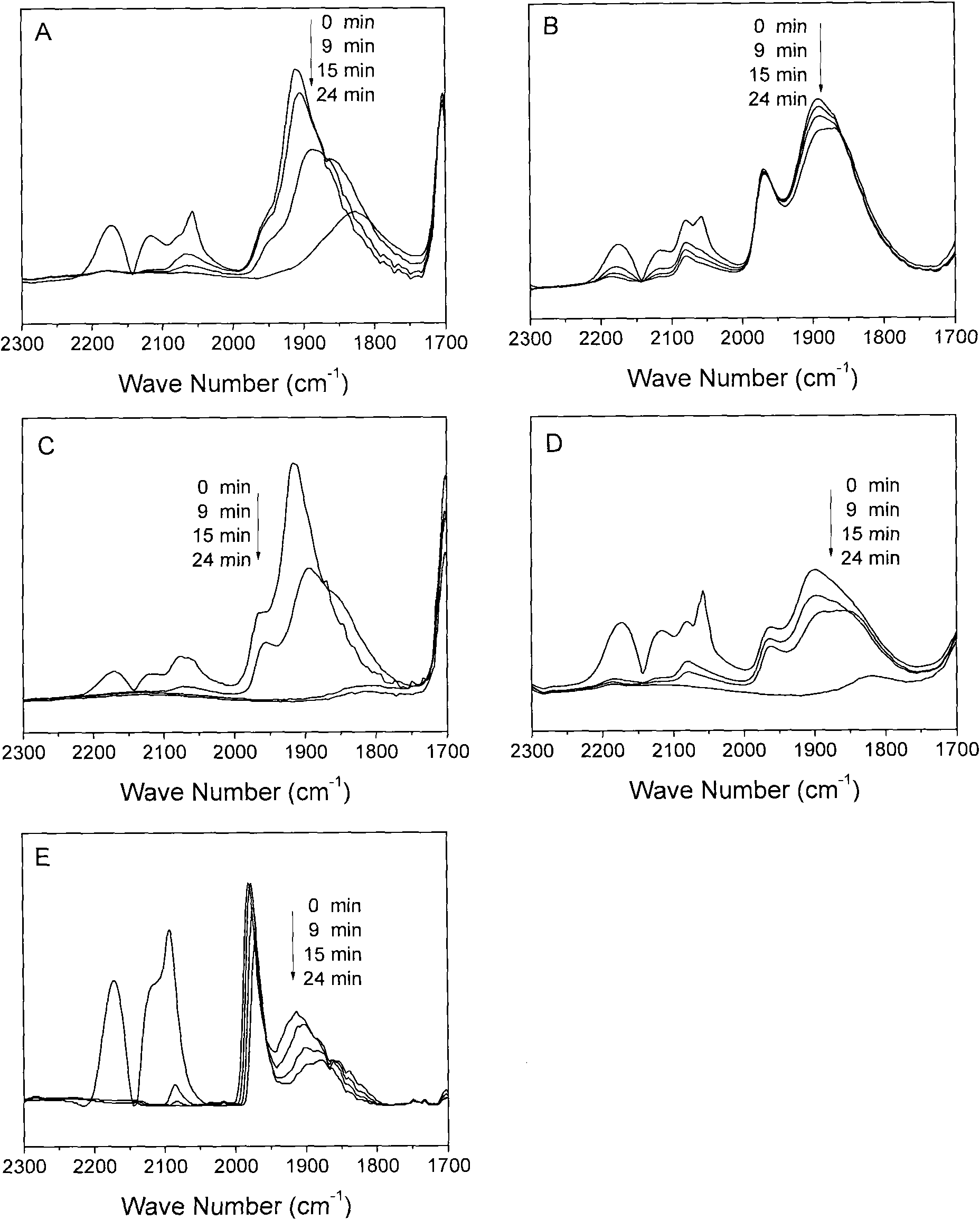

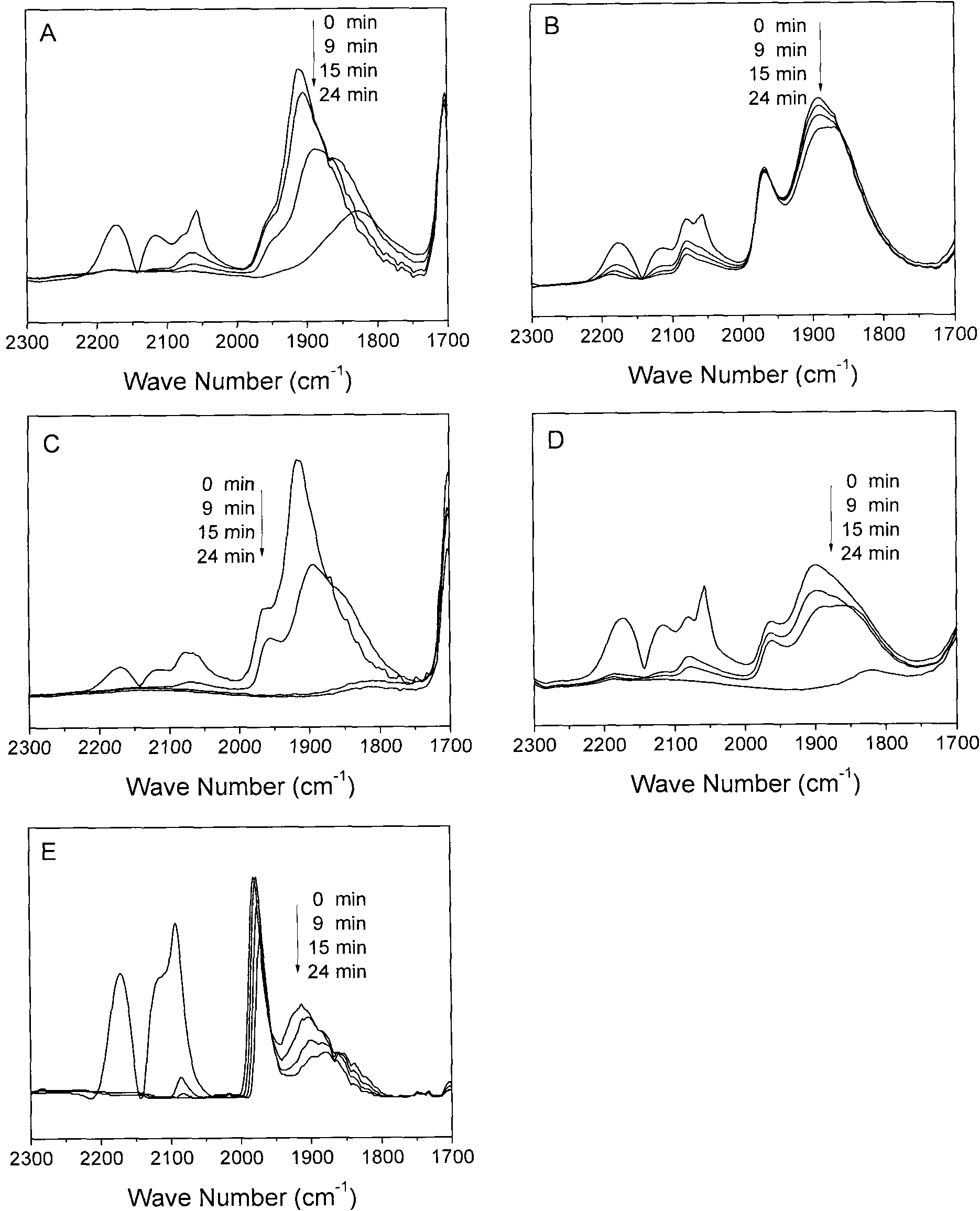

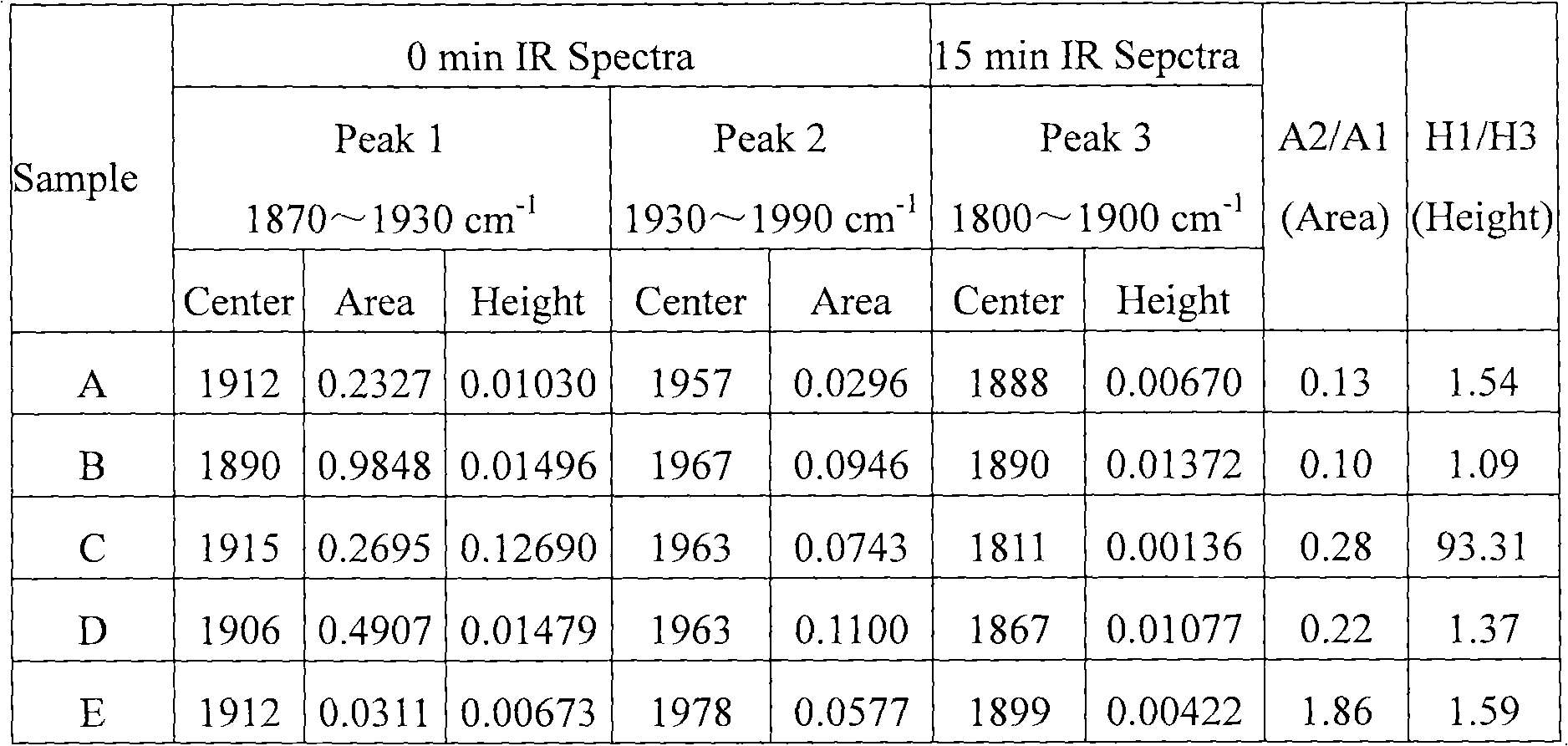

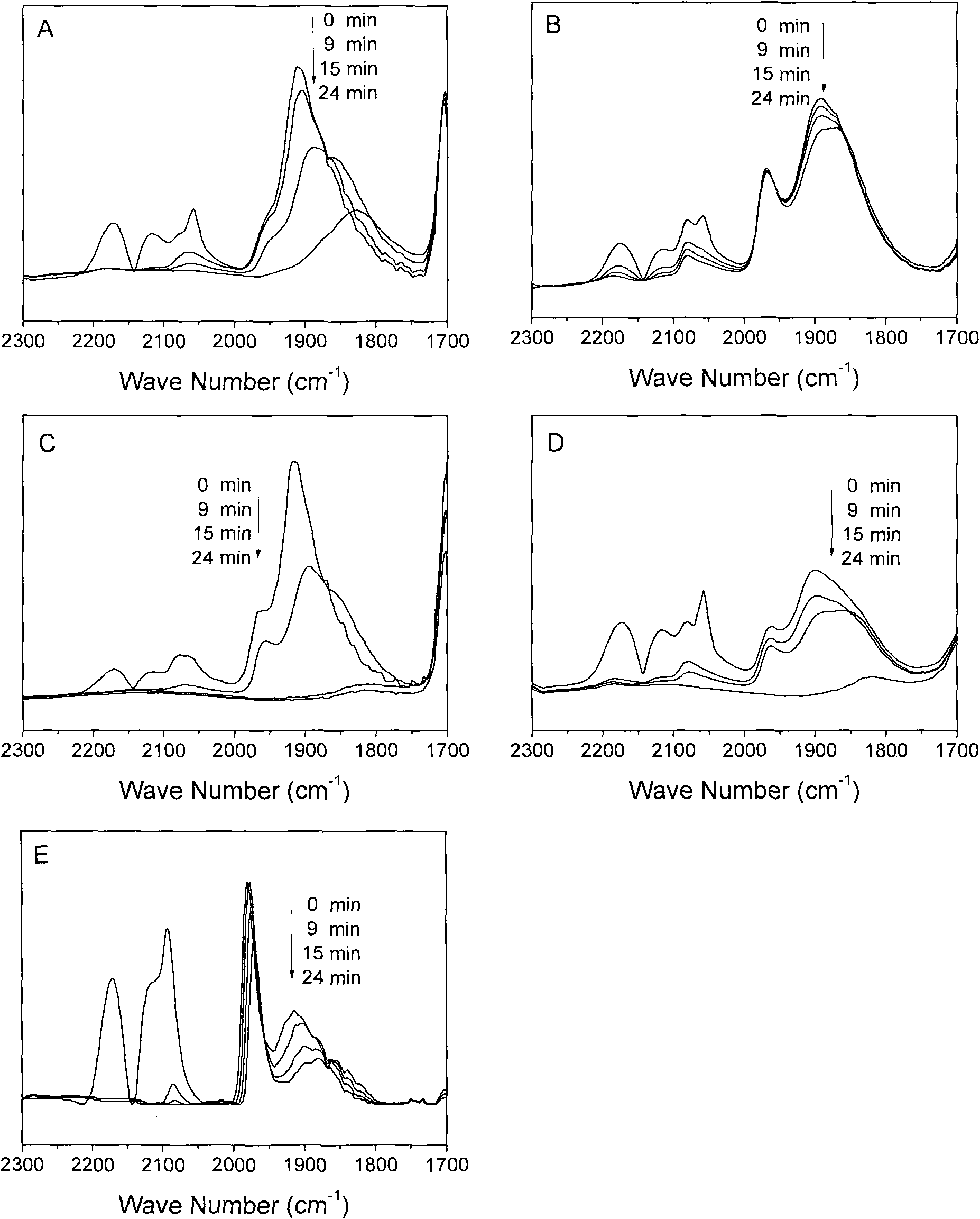

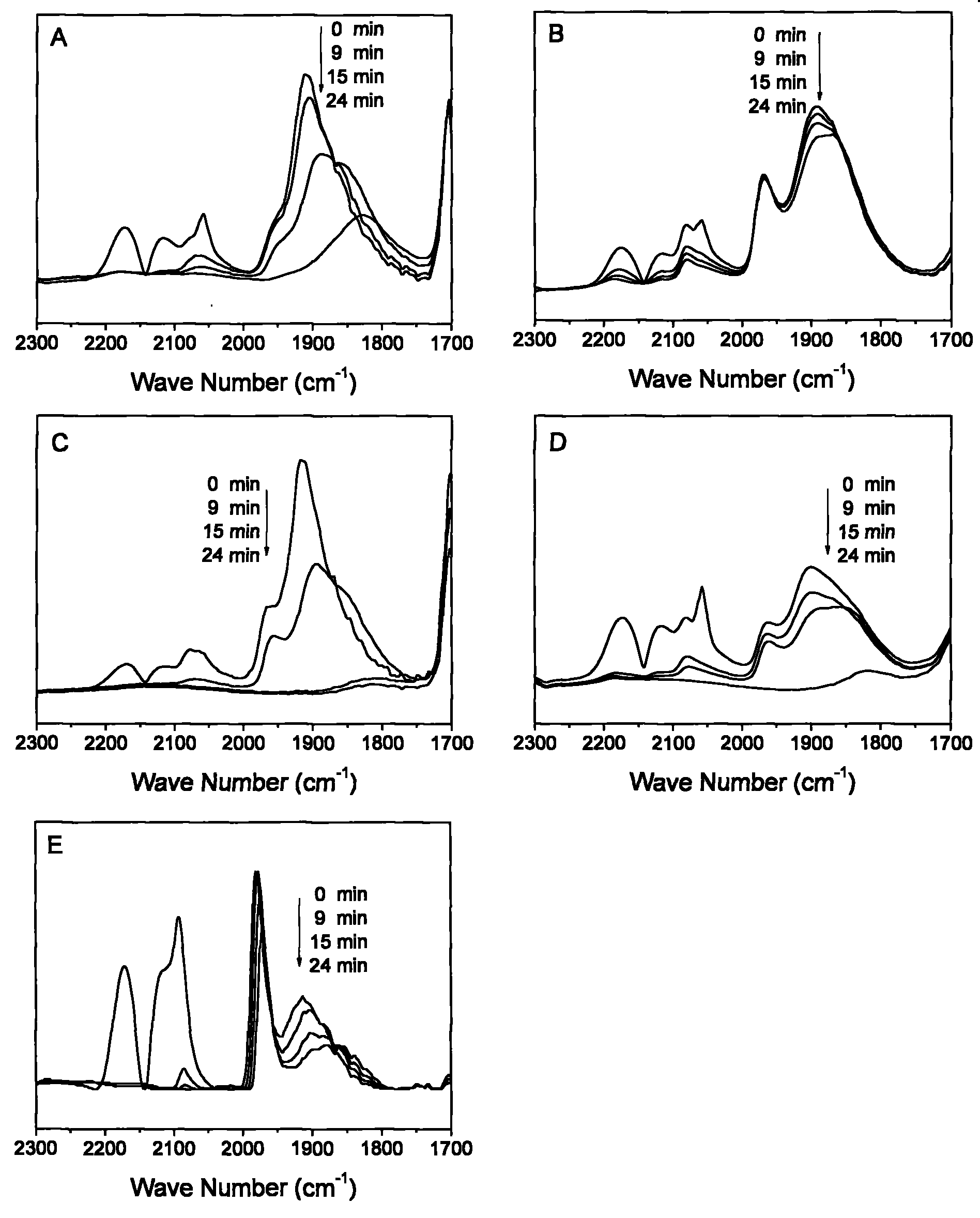

The invention provides a selective hydrogenation method of alkyne and alkadiene in a C4 hydrocarbon material flow. The method provided by the invention comprises the following steps of: adding the C4 hydrocarbon material flow containing alkyne and / or alkadiene and hydrogen gas into a hydrogenation reactor which is filled with a load type palladium catalyst; carrying out the selective hydrogenation on the alkyne and / or alkadiene in the C4 hydrocarbon material flow to form olefin when an inlet temperature is in a range of 10-80 DEG C, a mol ratio of the hydrogen gas to the sum of the alkyne and the alkadiene is 1-10 and a reaction pressure is in a range of 0.1-4 Mpa, and removing the olefin, wherein the load type palladium catalyst comprises a carrier, palladium and selective modified components; testing the load type palladium catalyst by utilizing a carbon monoxide adsorption in-situ infrared spectroscopy at the temperature of 40 DEG C to obtain an area ratio of a bridge type absorption peak at the 1930-1990cm<-1> to a bridge type absorption peak at the 1870-1930cm<-1> in an obtained infrared spectrogram is less than 0.2, more preferably less than 0.15. The method provided by the invention has a high selectivity to the selective hydrogenation of the alkyne and the alkadiene in the C4 hydrocarbon material flow and can be operated for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation method of alkyne and dialkene in alkene stream

ActiveCN102249834AGuaranteed reaction selectivityGuaranteed reactivityPhysical/chemical process catalystsHydrocarbon by hydrogenationIn situ infrared spectroscopyHydrogenation reaction

The invention provides a selective hydrogenation method of alkyne and dialkene in an alkene stream. The method comprises the steps that: an alkene stream containing alkyne and / or dialkene, and hydrogen are delivered into a hydrogenation reactor provided with a supported palladium catalyst; alkyne and / or dialkene in the alkene stream are hydrogenated into alkene under conditions of: a temperature in of 10 to 80 DEG C, a molar ratio of hydrogen to a total amount of alkyne and dialkene of 1 to 10, and a reaction pressure of 0.1 to 4 Mpa, such that alkyne and / or dialkene in the alkene stream are removed. The supported palladium catalyst comprises a carrier, palladium and optional modifying components. With a carbon monoxide adsorption in situ infrared spectroscopy method, the catalyst is tested under a temperature of 40 DEG C. In an obtained infrared spectrogram, an area ratio of an overhead absorption peak at a location of 1983 to 1990cm-1 to that at the location of 1870 to 1930cm-1 is lower than 0.2, and preferably 0.15. The method provides a high selectivity in the selective hydrogenation of alkyne and dialkene. The method can operate for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

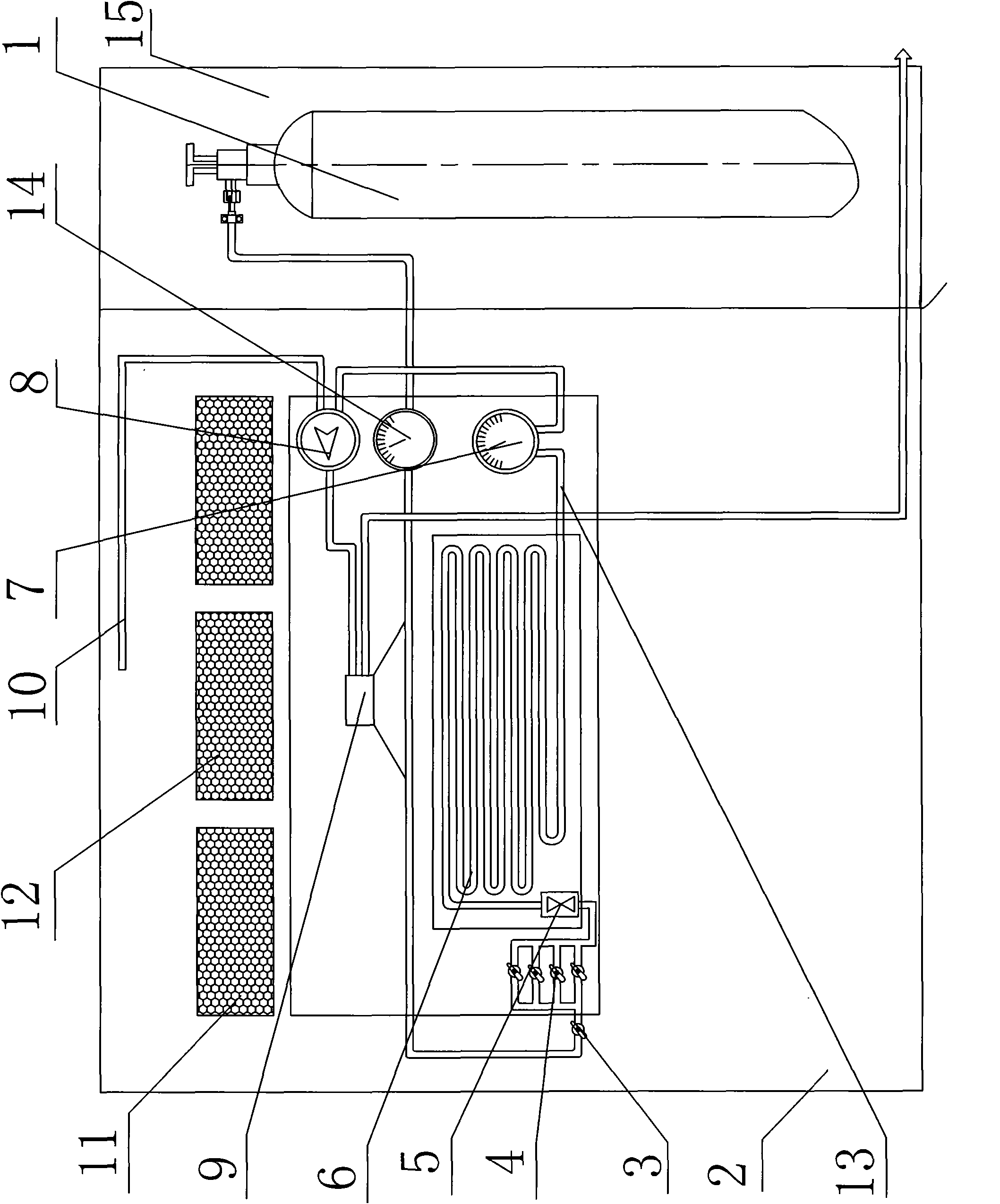

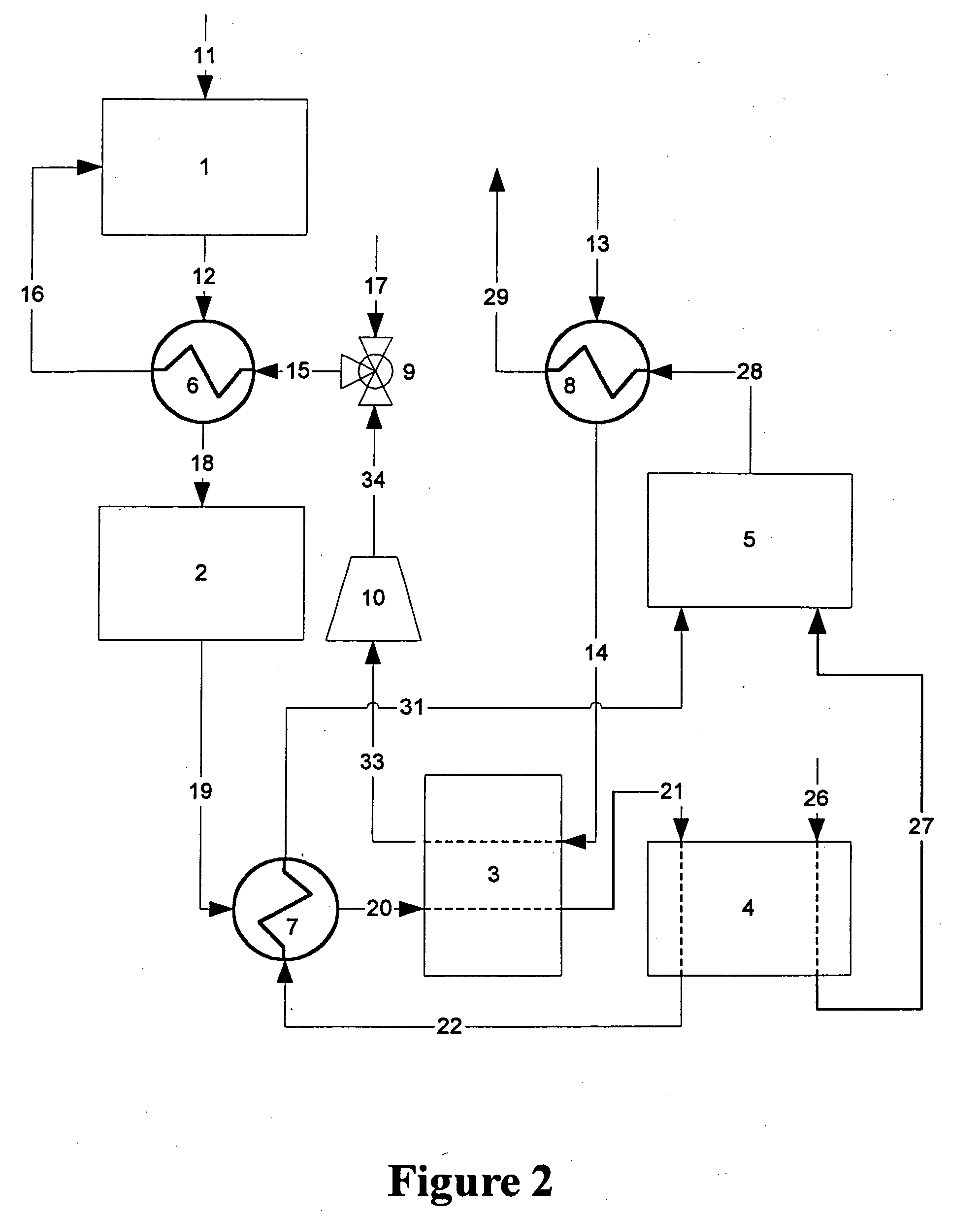

Cooling and dehumidifying system of underground shelter

InactiveCN102022132ARealize automatic air convectionRealize the function of cooling and dehumidificationTunnel/mines ventillationSafety equipmentsEmergency rescueEngineering

The invention relates to a cooling and dehumidifying system of an underground shelter. The arrangement and use of mine emergency shelters in underground mines are important measures in mine emergency rescue, and the mine emergency shelters are successful in rescue for multiple times. The cooling and dehumidifying system of the underground shelter comprises a refrigerant bottle (1), an equipment compartment (15) and a main compartment(2), wherein the refrigerant bottle is arranged in the equipment compartment and is connected with a main valve (3) through a high pressure gauge (14), and the main valve is connected with a throttle valve (4); the throttle valve is connected with an expansion valve (5), and the expansion valve is connected with an evaporator (6); the evaporator is connected with a low pressure gauge (7), and the low pressure gauge is connected with a reversing valve (8); and the reversing valve is connected with a pneumatic fan (9) and is connected with a high-pressure air pipe (10), and a carbon monoxide adsorbent device (11) and a carbon dioxide adsorbent device (12) are arranged in the main compartment. The invention is used for the underground shelter.

Owner:黑龙江龙煤卓异救援装备科技有限公司

Preparation method of carbon monoxide absorbent

InactiveCN105749858AShort modification timeIncrease the degree of ion exchangeGas treatmentOther chemical processesMicrowave radiometryCerium nitrate

The invention discloses a preparation method of carbon monoxide absorbent which is mainly applicable to the resource recycling of carbon monoxide in yellow phosphorus tail gas and belongs to the field of flue gas purification.The preparation method includes: using NaY type molecular sieve as the carrier to prepare CuCl2 solution, adding the molecular sieve into the CuCl2 solution, adding an appropriate amount cerium nitrate, using a microwave radiation method to perform ion exchanging on the molecular sieve, drying, and calcining the molecular sieve after the exchanging to obtain the absorbent.The absorbent needs to be reductively activated by oxygen before being used, and the used molecular sieve can be desorbed through vacuumizing or heating.The prepared absorbent is short in modification time, high in ion exchanging degree, even in active substance dispersion, high in molecular sieve catalytic activity and promising in industrial application prospect.

Owner:KUNMING UNIV OF SCI & TECH

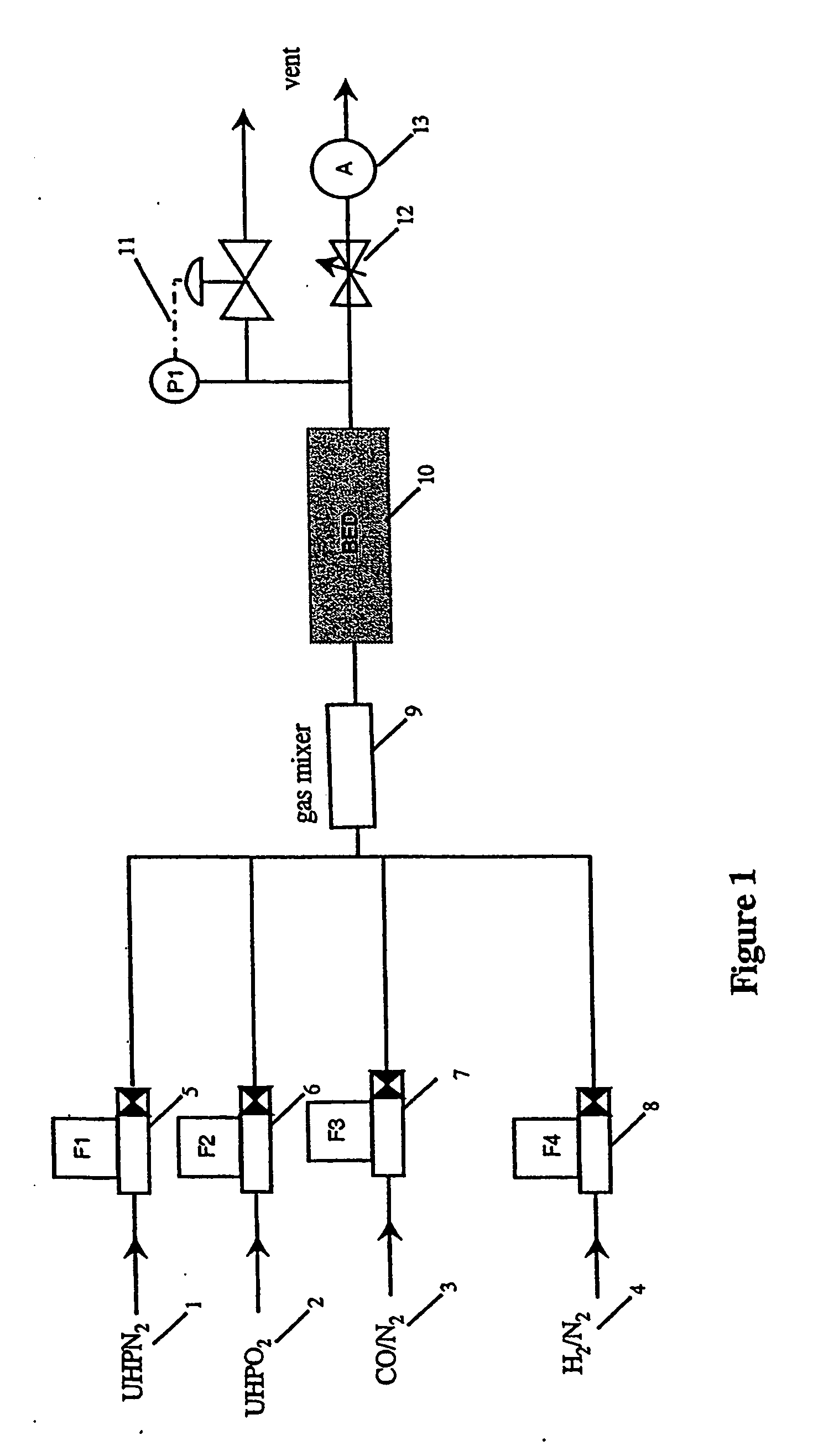

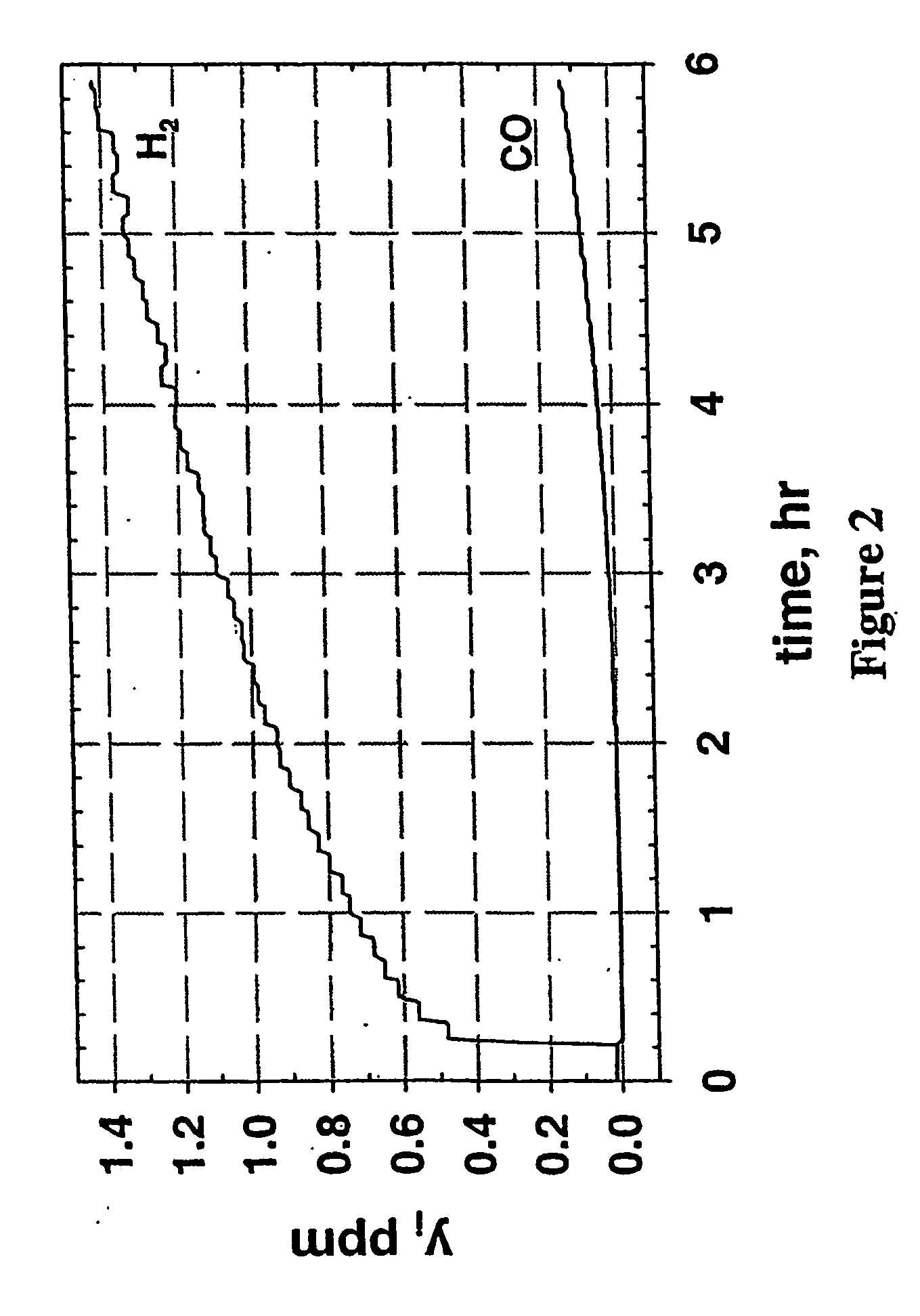

Production of carbon monoxide-free hydrogen and helium from a high-purity source

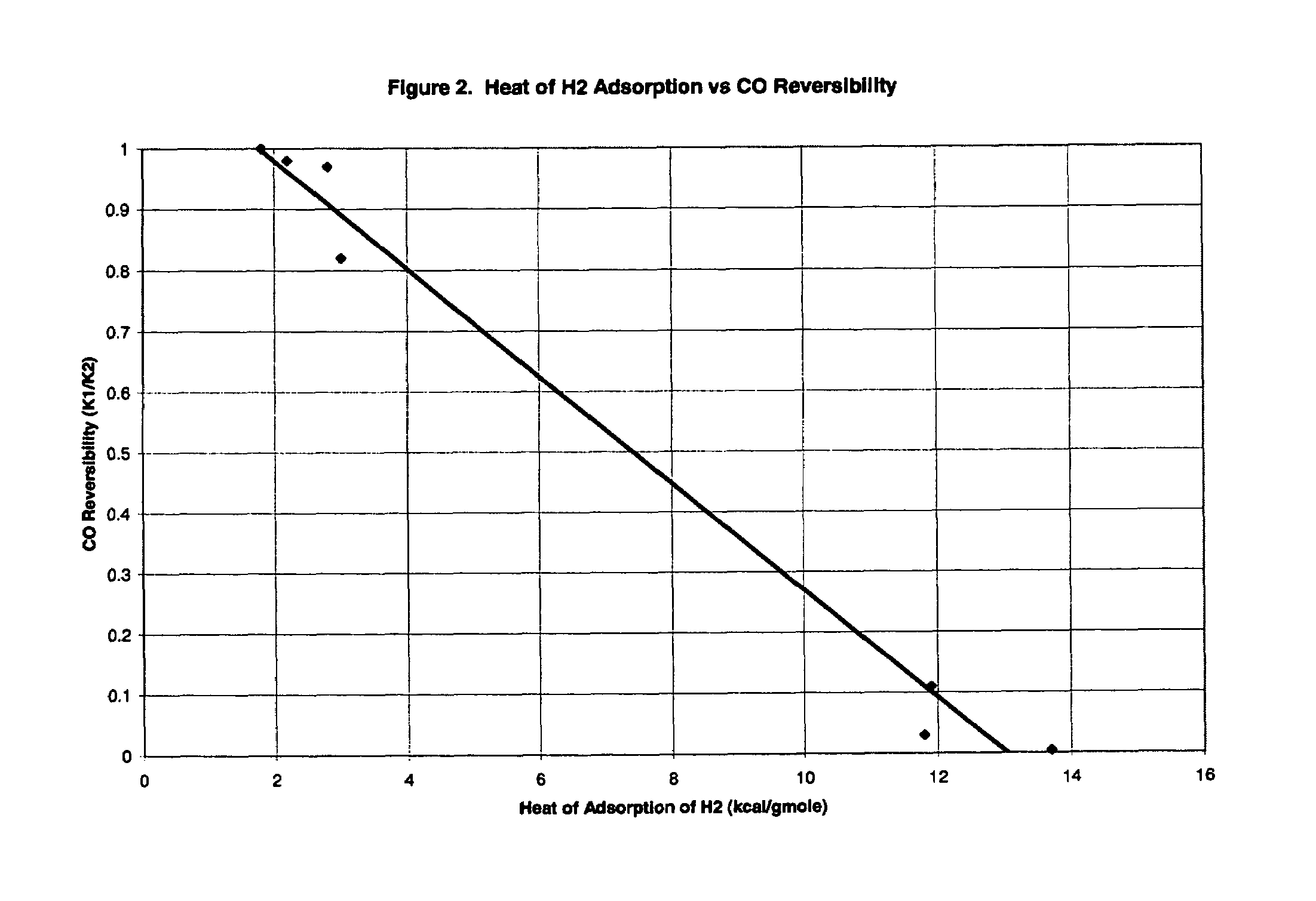

The invention provides vacuum swing adsorption processes that produce an essentially carbon monoxide-free hydrogen or helium gas stream from, respectively, a high-purity (e.g., pipeline grade) hydrogen or helium gas stream using one or two adsorber beds. By using physical adsorbents with high heats of nitrogen adsorption, intermediate heats of carbon monoxide adsorption, and low heats of hydrogen and helium adsorption, and by using vacuum purging and high feed stream pressures (e.g., pressures of as high as around 1,000 bar), pipeline grade hydrogen or helium can purified to produce essentially carbon monoxide -free hydrogen and helium, or carbon monoxide, nitrogen, and methane-free hydrogen and helium.

Owner:AIR PROD & CHEM INC

Carbon monoxide adsorbent

ActiveCN103418337AImprove adsorption capacityReasonable compositionOther chemical processesMolecular sieveKneader reactor

A carbon monoxide adsorbent comprises the following raw materials, by weight: 38 to 42% of cuprous chloride, 18 to 23% of 13X molecular sieves, 8 to 10% of aluminium hydroxide, and 28 to 35% of purified attapulgite powder. The adsorbent is produced by the following steps: a. the 13X molecular sieves are baked in a 200 DEG C oven for 120 to 150 minutes; b. the four raw materials are mixed into a mixed material, which is put into a kneader, purified water, the weight of which is 10% of that of the mixed material, is added into the kneader for kneading for 20 to 25 minutes, and kneaded material is obtained; c. the kneaded material is then processed by an strip extruder into strip-shaped objects with sizes between phi 3 mm * 8 mm and phi 3 mm * 15 mm; and d. the strip-shaped objects are put into the oven, baked at a temperature between 300 and 320 DEG C for 180 to 200 minutes, then taken out, and made into the carbon monoxide adsorbent after natural cooling. The carbon monoxide adsorbent is scientific in combination. Especially by adding 200 mesh purified attapulgite powder which undergoes crushing, purification, ultrafine processing and activation processing, the carbon monoxide adsorbent is improved in adsorption capability and substantially lowered in cost. The price of the carbon monoxide adsorbent is two thirds of those of similar products.

Owner:程会 +1

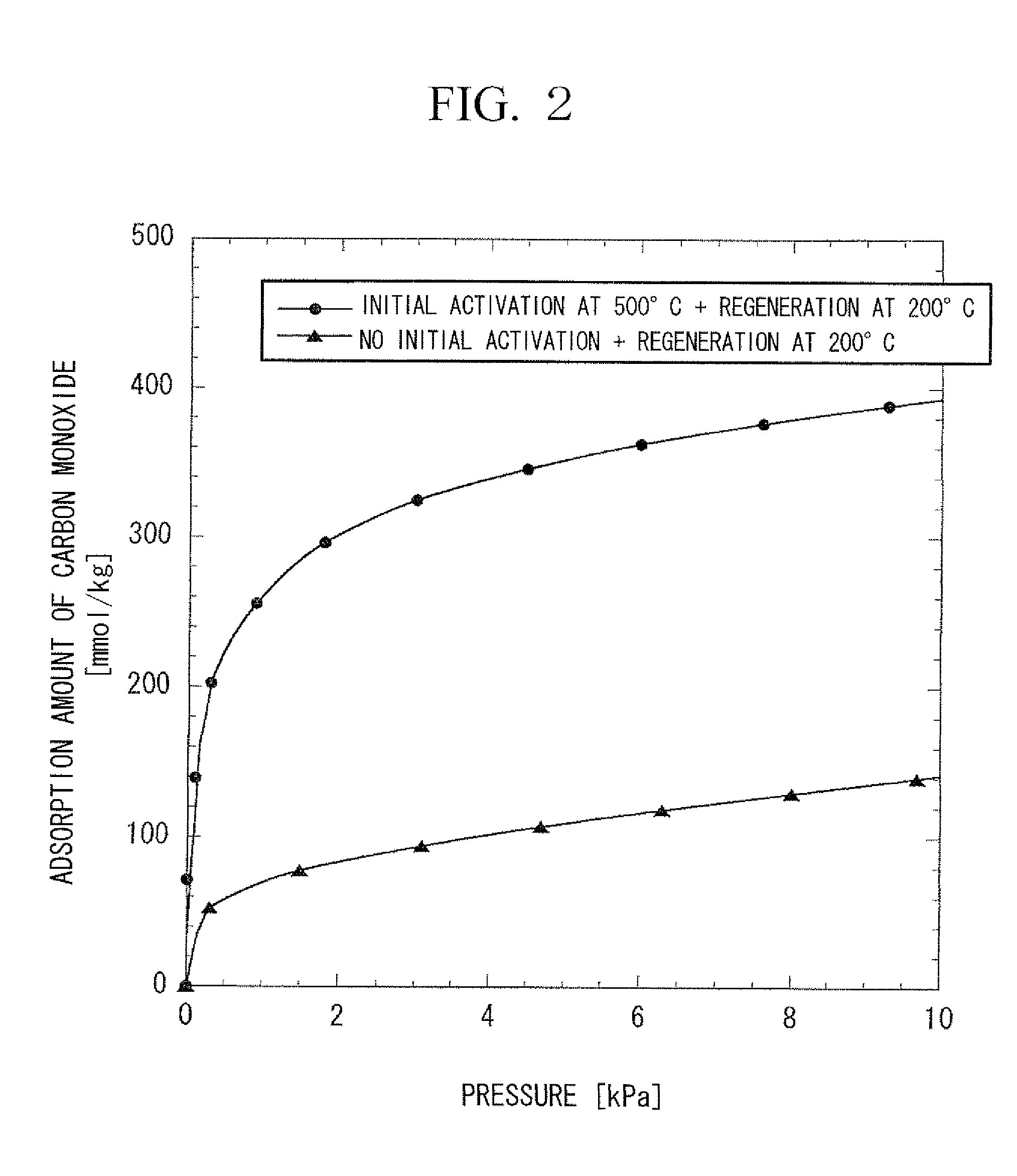

Adsorbent for carbon monoxide, gas purification method, and gas purification apparatus

The adsorbent for carbon monoxide of the present invention is obtained by activating a Cu-ZSM5 type zeolite prepared as a catalyst for removal of NOX through heating at 450 to 600° C. in an inert gas atmosphere containing no moisture. The gas purification method of the present invention includes removing carbon monoxide as a trace amount of impurities contained in a gas by a temperature swing adsorption method, wherein the adsorbent for carbon monoxide according to claim 1 is used, and a regeneration operation of the adsorbent for carbon monoxide is carried out at 200 to 350° C.

Owner:NIPPON SANSO CORP

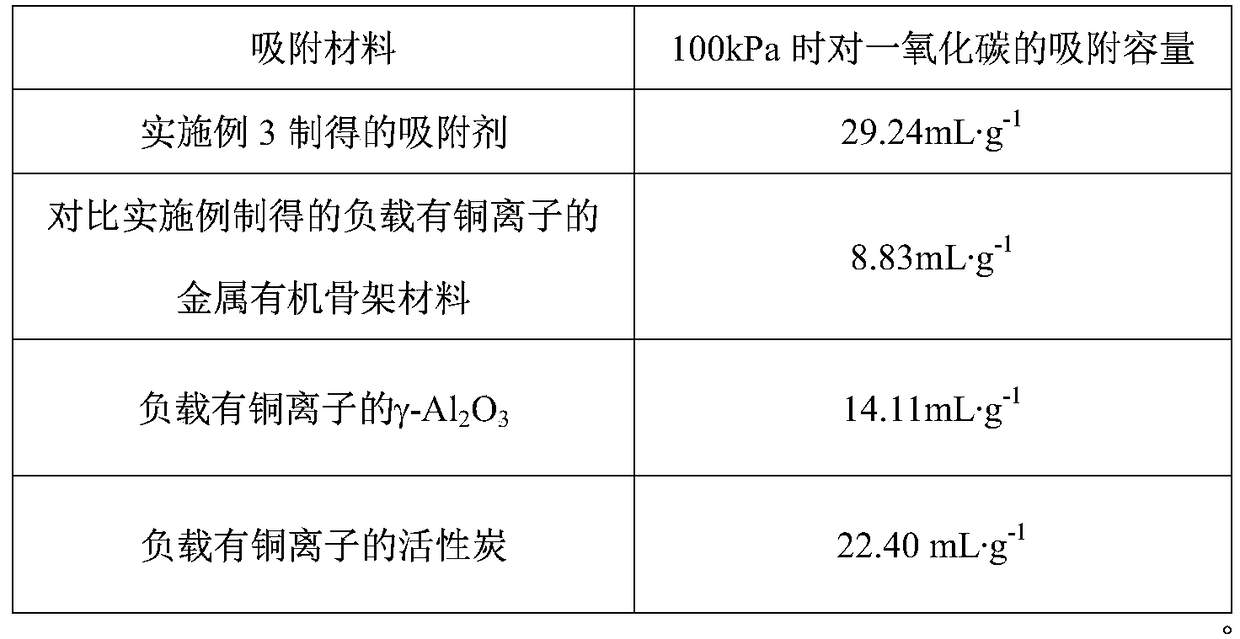

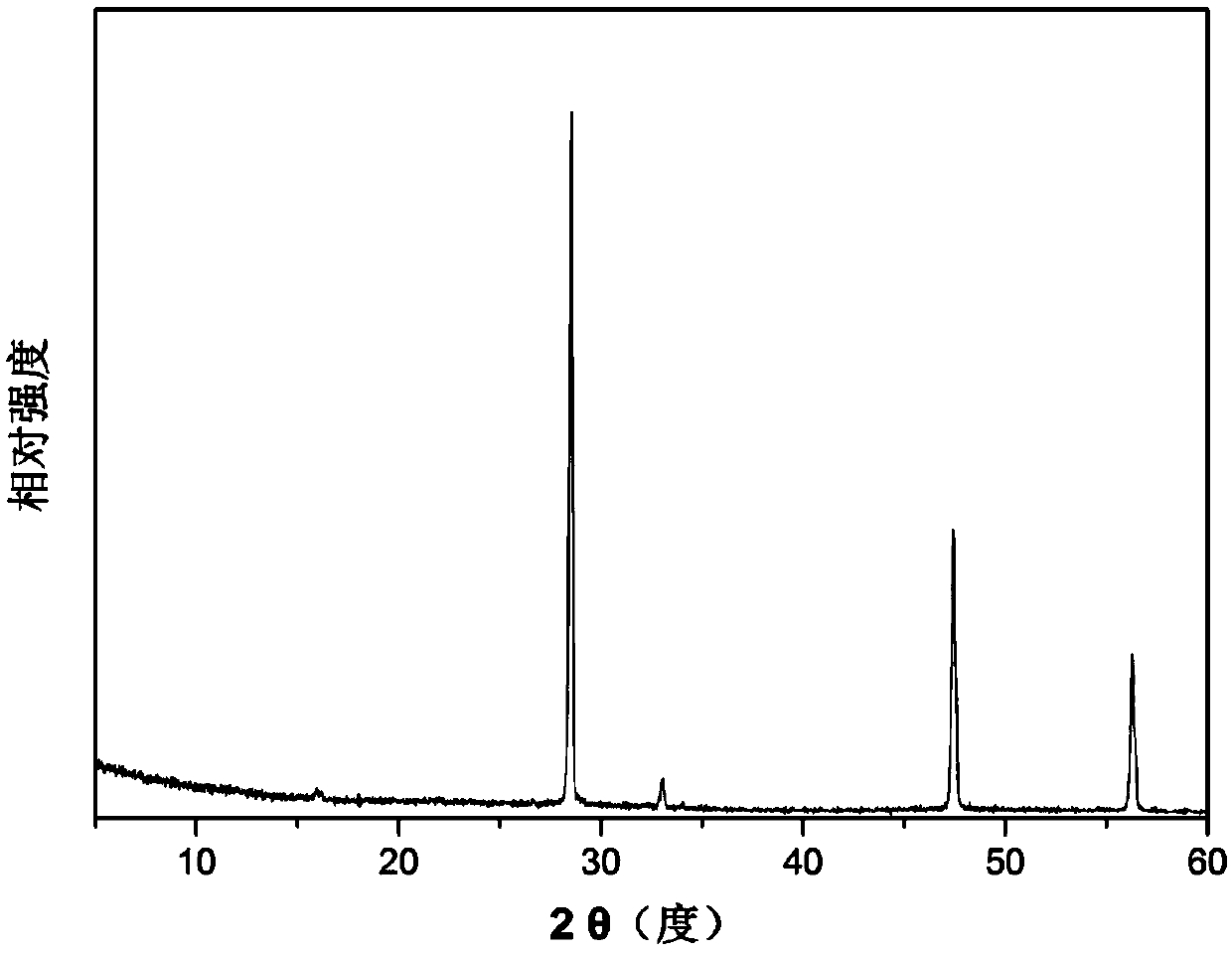

Carbon monoxide adsorbent prepared from MOF (metal organic framework) material as carrier as well as preparation method and application of carbon monoxide adsorbent

ActiveCN108421532AStructurally intactImprove adsorption capacityGas treatmentOther chemical processesSorbentMetal-organic framework

The invention discloses a carbon monoxide adsorbent prepared from an MOF (metal organic framework) material as a carrier. The adsorbent adopts the MOF material as the carrier, then bivalent copper salt and trivalent vanadium salt are introduced onto the carrier material simultaneously, and the MOF material loaded with copper ions and vanadium ions simultaneously is obtained. The invention furtherdiscloses a preparation method of the carbon monoxide adsorbent and an application of the carbon monoxide adsorbent to adsorptive separation of carbon monoxide. According to the adsorbent, bivalent copper salt and trivalent vanadium salt are introduced into the MOF simultaneously, bivalent copper can be reduced into monovalent copper at a lower temperature lower than or equal to 250 DEG C on the basis of weak reduction property of trivalent vanadium salt, so that the MOF structure is retained in good condition, and the adsorbent is a Pi-complexation adsorption material with an undamaged structure and has good adsorption performance for carbon monoxide.

Owner:JIANGSU UNIV OF SCI & TECH

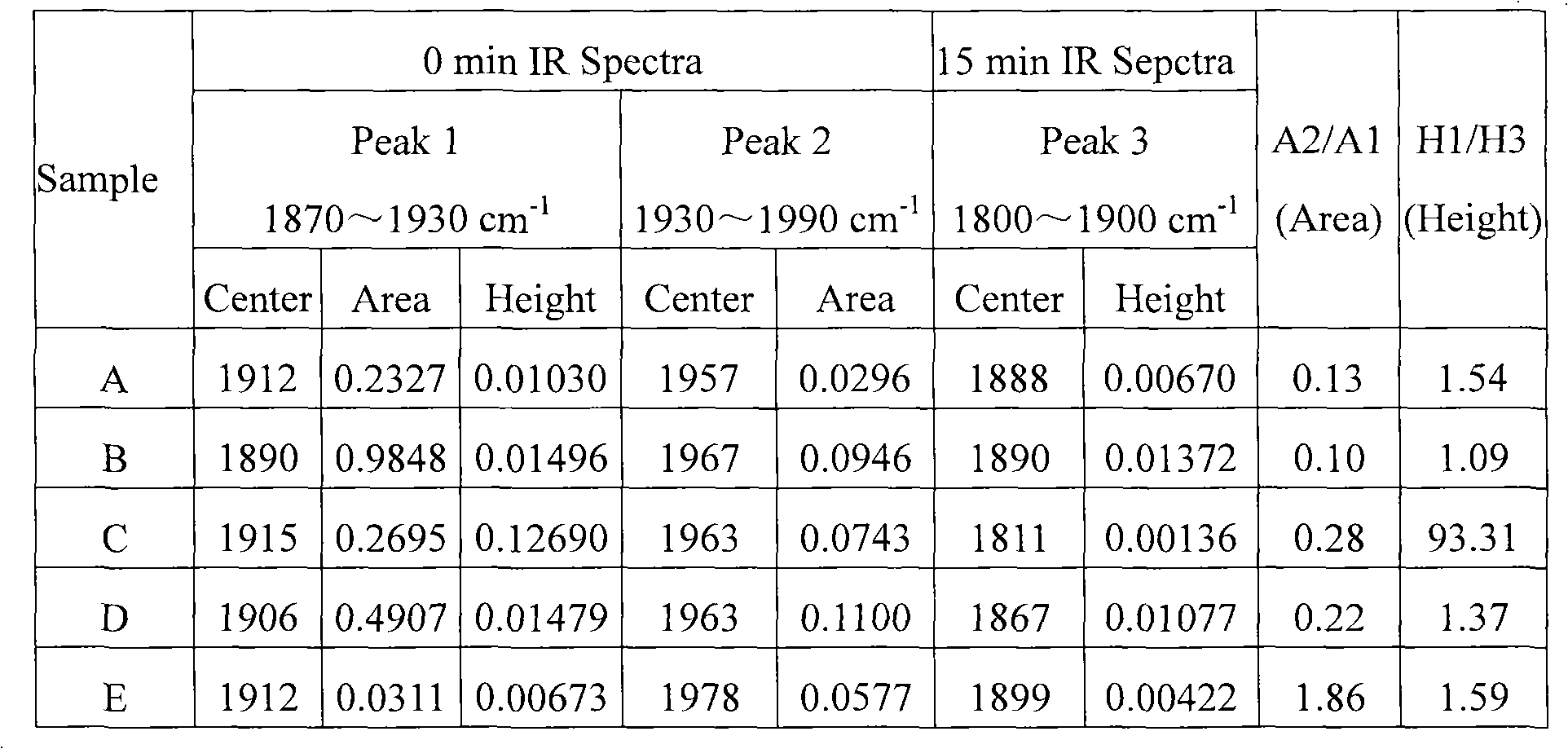

Supported palladium catalyst with characteristic of specific infrared absorption

ActiveCN102247838AGood choiceHigh activityMetal/metal-oxides/metal-hydroxide catalystsIn situ infrared spectroscopyBridge type

The invention discloses a supported palladium catalyst with characteristic of specific infrared absorption, comprising a carrier, palladium and optional modifying component. For finding a noble metal catalyst with good catalytic performance accurately and effectively, the carbon monoxide adsorption in-situ infrared spectroscopy is used for testing the catalyst at the temperature of 40 DEG C, in the obtained infrared spectrum, the ratio of the area of a bridge type absorption peak at the value of 1930-1990 cm<-1> to the area of a bridge type absorption peak at the value of 1870-1930 cm<-1> is less than 0.2, and more preferably 0.15. In addition, preferably, the ratio of the peak height of an absorption peak at the value of 1870-1930 Cm<-1> in the in-situ infrared spectrogram obtained by testing the catalyst when being purged with nitrogen gas for 0 min to the peak height of an absorption peak at the value of 1800-1900 cm<-1> in the in-situ infrared spectrogram obtained by testing the catalyst when being purged with nitrogen gas for 15 min is less than 5, and more preferably 2. The catalyst has excellent reaction selectivity and activity, and the preparation method of the catalyst is easy to operate and saves energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

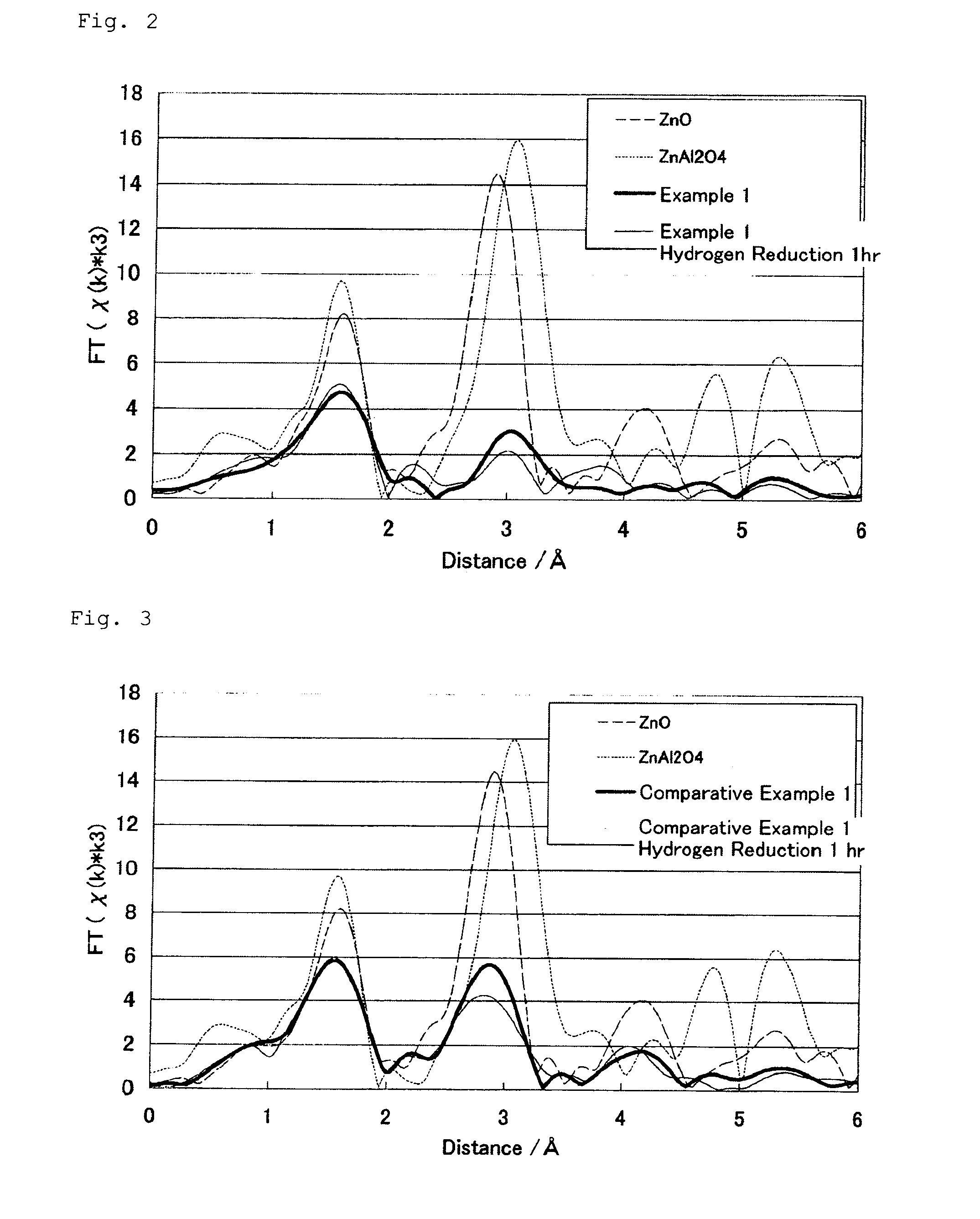

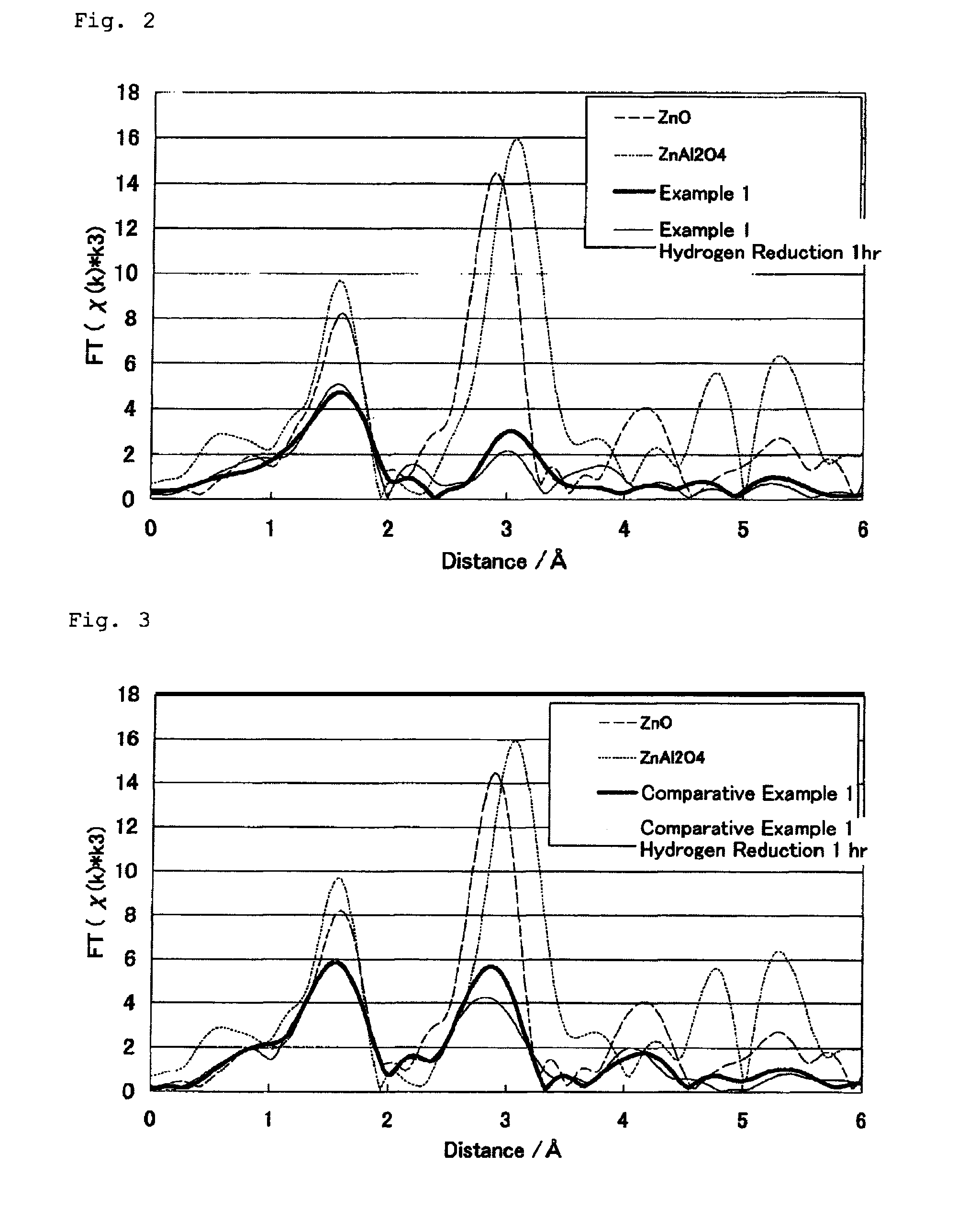

Catalyst for carbon monoxide conversion and method of carbon monoxide modification with the same

InactiveUS20100015023A1High activityIncreased durabilityHydrogenFinal product manufactureFuel cellsHydrogen

The invention provides a catalyst for carbon monoxide conversion, comprising from 10 to 90% by mass of a copper oxide ingredient, from 5 to 50% by mass of a zinc oxide ingredient and from 10 to 50% by mass of an aluminum oxide ingredient, and having a specific surface area of from 100 to 300 m2 / g, a carbon monoxide adsorption of from 20 to 80 μmol / g, and a copper oxide crystallite diameter of at most 200 angstroms, as a catalyst suitable for carbon monoxide conversion for fully reducing carbon monoxide in the hydrogen gas obtained through reforming of a starting hydrocarbon material, for the purpose of enabling stable long-term operation of a fuel cell which uses hydrogen gas as a fuel and which is frequently and repeatedly started and stopped.

Owner:IDEMITSU KOSAN CO LTD

Selective hydrogenation method for allylene and allene in propylene material flow

ActiveCN102249836AGuaranteed reaction selectivityGuaranteed reactivityHydrocarbon by hydrogenationHydrocarbon purification/separationHydrogenation reactionPalladium catalyst

The invention provides a selective hydrogenation method for allylene and allene in propylene material flow. The method comprises the following steps of: introducing the propylene material flow containing 1-(methylamino)-2,3-propanediol (MAPD) and hydrogen into a hydrogenation reactor filled with a supported palladium catalyst, and performing selective hydrogenation on the MAPD in the propylene material flow at the inlet temperature of between 10 and 80 DEG C and a molar ratio of the hydrogen to the MAPD of 1-5 under the reaction pressure of 0.1-4Mpa, so that the MAPD becomes propylene and is removed, wherein the catalyst comprises a carrier, palladium and optional modifying components; and a carbon monoxide adsorption in situ infrared ray spectroscopy is used for testing the catalyst at 40DEG C, and an area ratio of a bridge absorption peak at a position of 1,930-1,990cm<-1> to a bridge absorption peak at a position of 1870-1,930cm<-1> in an infrared spectrum is less than 0.2 and preferably less than 0.15. By the method, the selective hydrogenation reaction for the allylene and allene in the propylene material flow has high selectivity, and can be stably performed for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

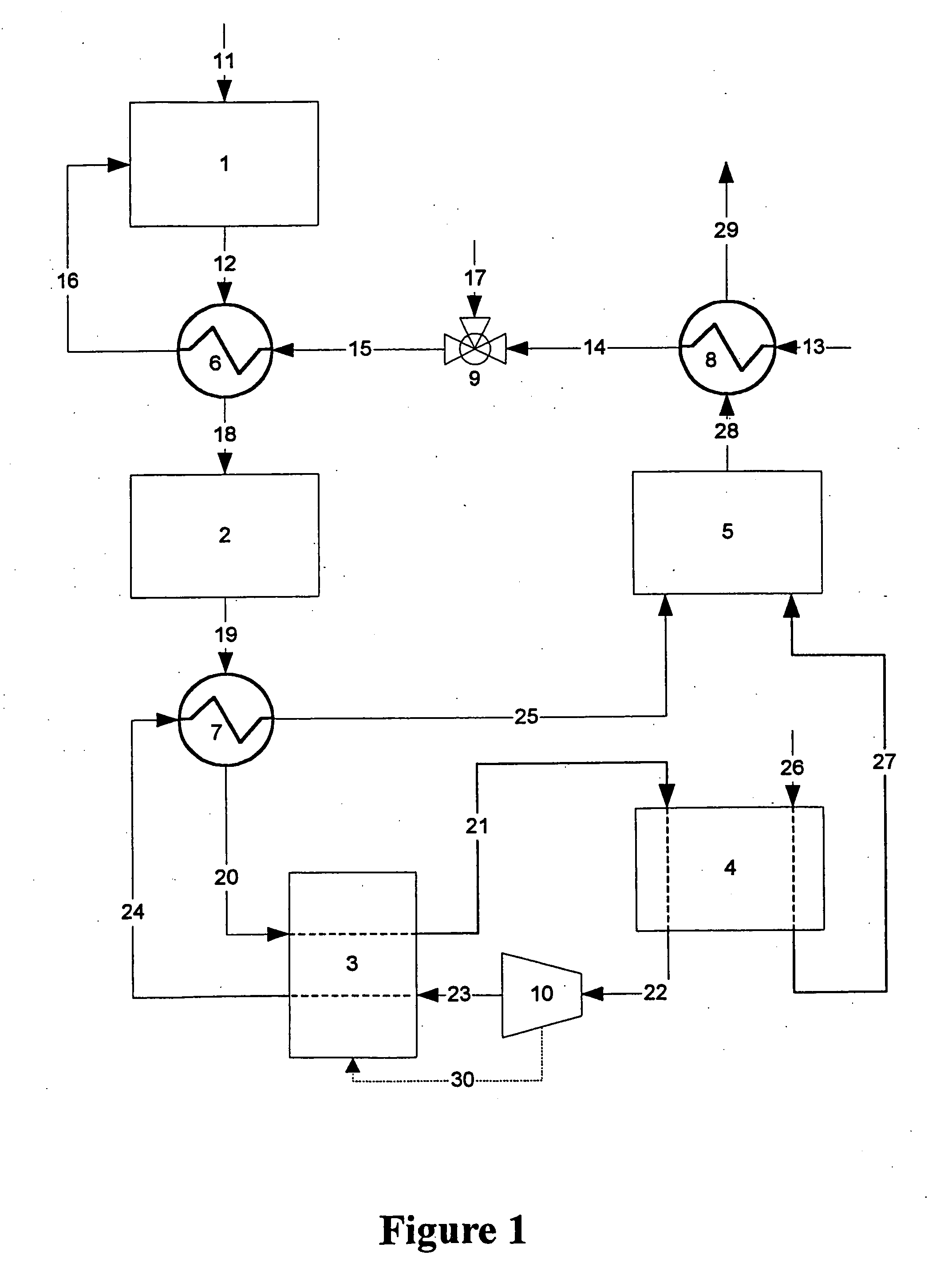

Carbon monoxide adsorption for carbon monoxide clean-up in a fuel cell system

InactiveUS20060032138A1Eliminate useReduce contentGas treatmentPhysical/chemical process catalystsSorbentHydrogen fuel cell

An apparatus removes carbon monoxide (CO) from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies of proton exchange membrane (PEM) fuel cells. A vessel houses a carbon monoxide adsorbent. The vessel may be a rotating pressure swing adsorber. A water gas shift reactor is upstream of the rotating pressure swing adsorber. The water gas shift reactor may include a second adsorbent adapted to adsorb carbon monoxide at low temperatures and to desorb carbon monoxide at high temperatures. The apparatus advantageously eliminates the use of a preferential oxidation (PROX) reactor, by providing an apparatus which incorporates CO adsorption in the place of the PROX reactor. This cleans up carbon monoxide without hydrogen consumption and the concomitant, undesirable excess low grade heat generation. The present invention reduces start-up duration, and improves overall fuel processor efficiency during normal operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

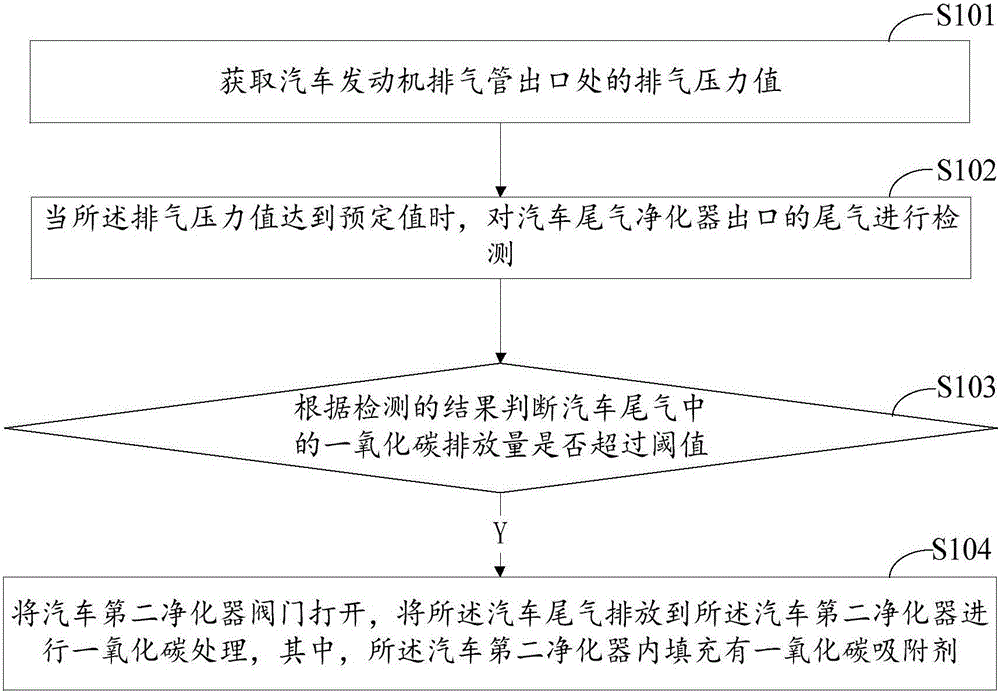

Purifying method of carbon monoxide in automobile exhaust

InactiveCN105822389AAvoid pollutionAvoid harmInternal combustion piston enginesExhaust apparatusExhaust pipeAutomotive emissions

The invention relates to a purifying method of carbon monoxide in automobile exhaust. The method comprises the steps of obtaining an exhaust pressure value in an exhaust pipe outlet of an automobile engine; detecting the exhaust in an outlet of an automobile exhaust purifier when the exhaust pressure value reaches a preset value; judging if the emission of the carbon monoxide in the automobile exhaust exceeds a threshold value or not according to the detecting result; and if yes, opening a valve of a second automobile purifier, and discharging the automobile exhaust into the second automobile purifier for carbon monoxide treatment, wherein the automobile second purifier is filled with a carbon monoxide absorbing agent. Through the method, if the automobile exhaust is secondarily treated through the exhaust pressure value and the carbon monoxide emission is judged to prevent the exhaust from polluting the environment.

Owner:黄安武

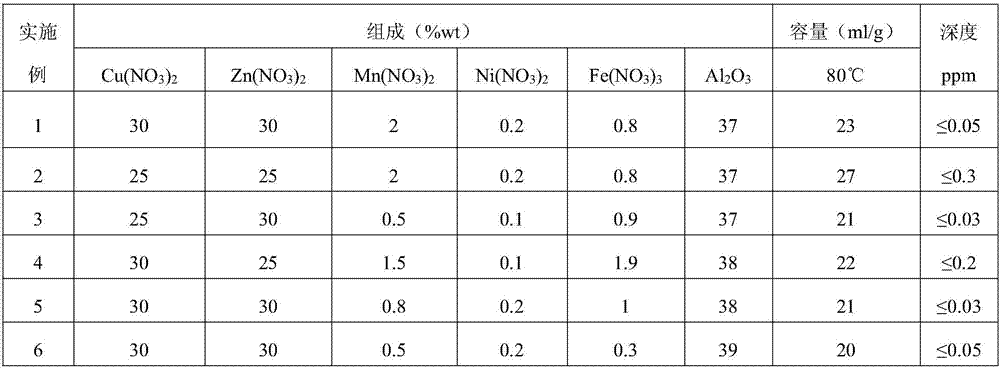

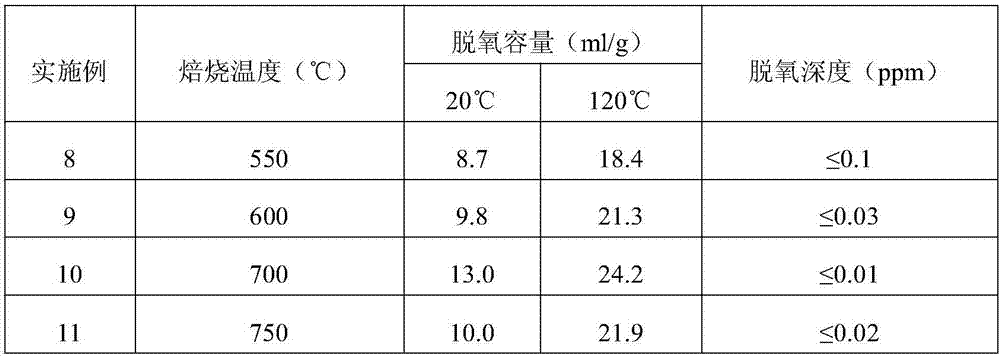

Multi-element high-activity component carbon monoxide adsorbent as well as preparation method and application thereof

ActiveCN106984259AReduce depthSmall removal capacityGas treatmentOther chemical processesSorbentChemical adsorption

The invention relates to a multi-element high-activity component carbon monoxide adsorbent as well as a preparation method and application thereof. The multi-element high-activity component carbon monoxide adsorbent is mainly prepared by an active component co-precipitation method; an active component comprises high-valence oxide of Cu, Zn, Mn, Ni and Fe: CuO, ZnO, MnOx, NiO and FeOy as well as dispersing agent Al2O3 powder. The multi-element high-activity component carbon monoxide adsorbent as well as the preparation method and application thereof have the benefits that by utilizing the characteristic of complementary performances of different components, the multiple components reach high-valence states through oxidation, and further, the ability to remove carbon monoxide by chemical adsorption is realized; the effect of a catalyst of the multi-element high-activity component carbon monoxide adsorbent is superior to that of a single or two-component catalyst; the multi-element high-activity component carbon monoxide adsorbent has the advantages of being free from loss of effective component of feed gas, high in removal depth, large in capacity, low in activation temperature, strong in anti-sintering ability, long in service life, high in mechanical strength, hard to pulverize and the like, is suitable for C2H4, C3H6, CH4, H2, N2, He, Ne, Ar, Kr, Xe and deep removal of the carbon monoxide by electron gas, and can be widely applied to large-scale industrial production.

Owner:大连圣得环保新材料有限公司

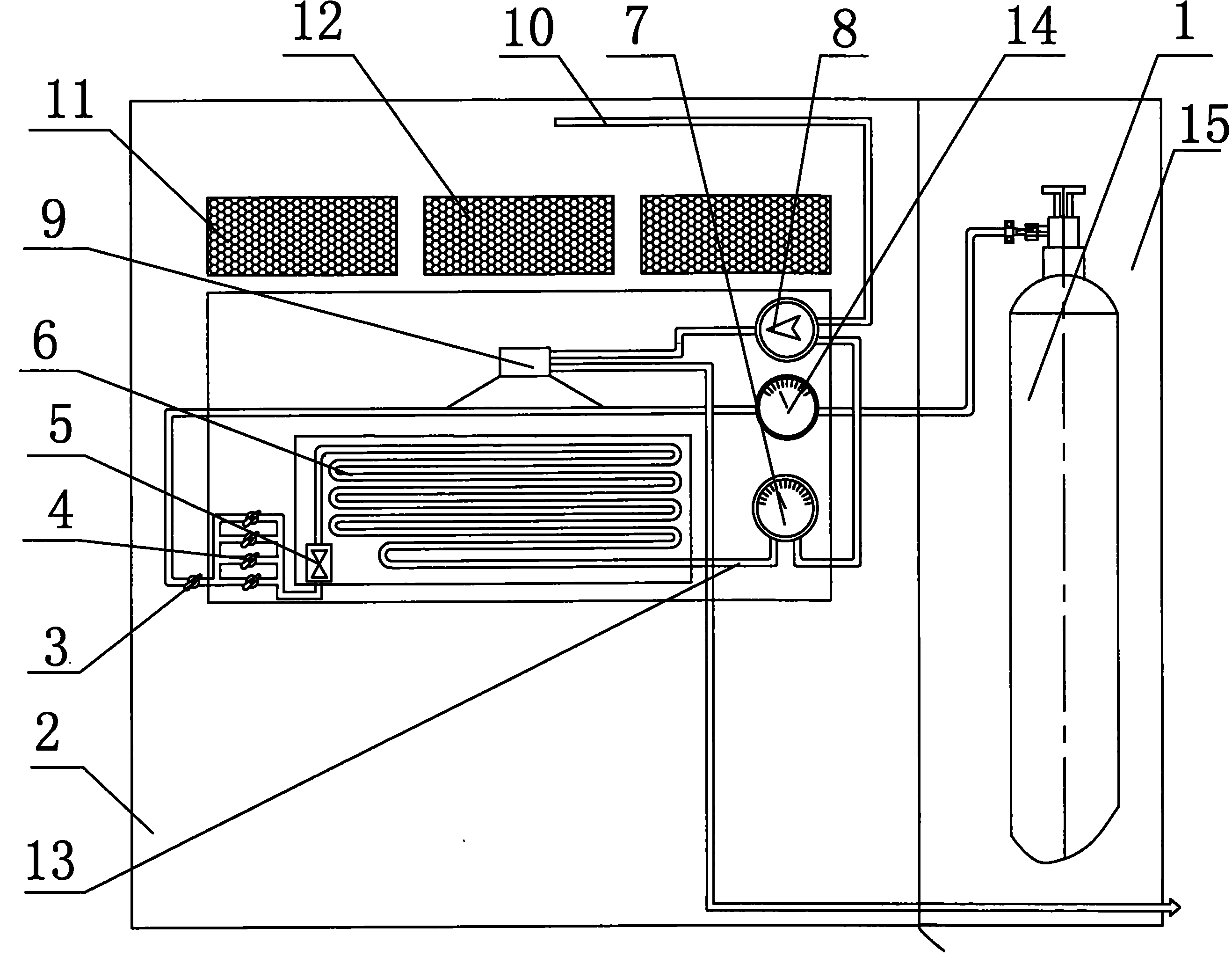

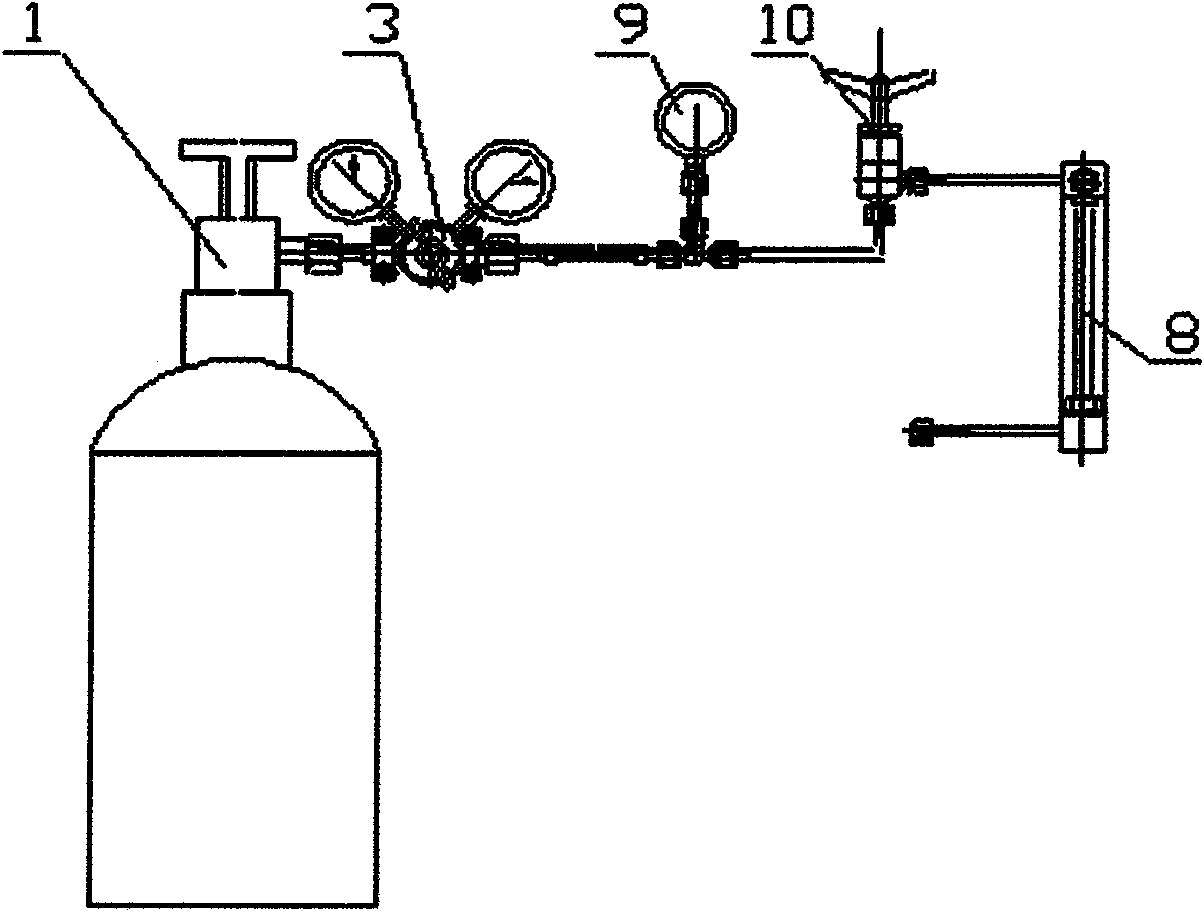

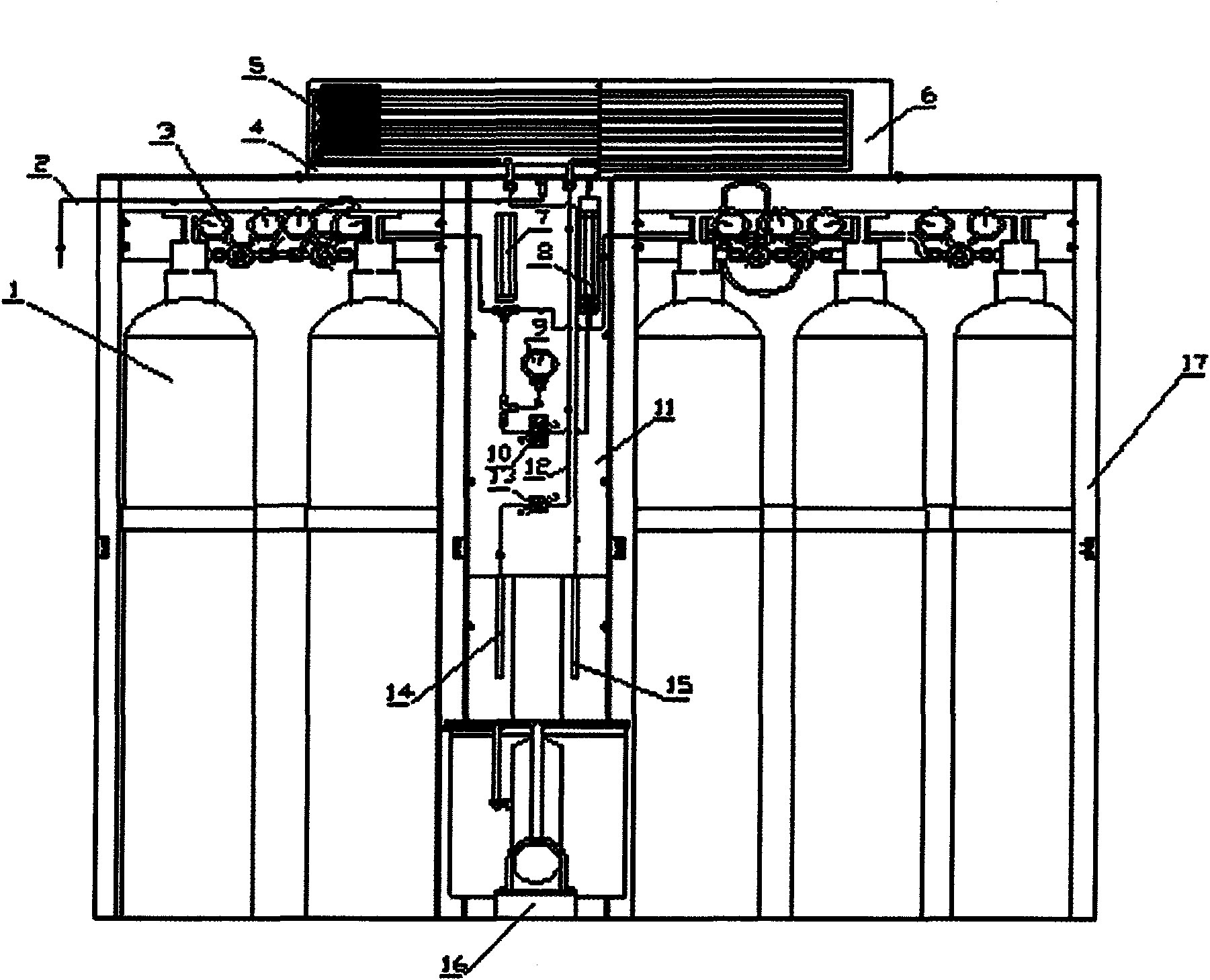

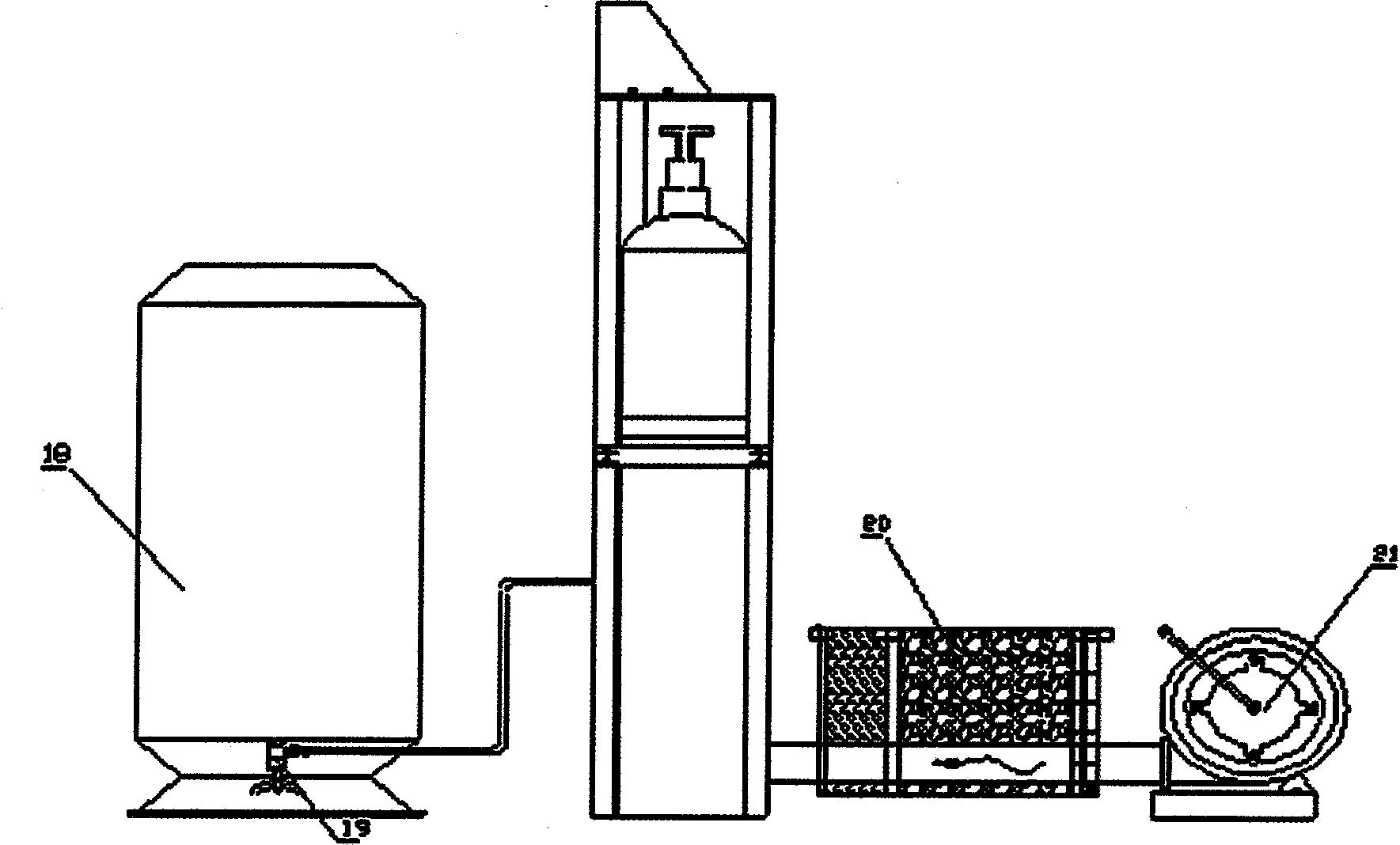

Non-electric drive life support device

InactiveCN102031989AGuaranteed to workDispersed particle separationFluid circulation arrangementEngineeringBottle

The invention relates to a non-electric drive life support device, comprising three subsystems, namely an oxygen supply subsystem used for supplying oxygen, a carbon dioxide / carbon monoxide absorption subsystem used for purifying the air and a temperature reduction and dehumidification subsystem used for controlling temperature and humidity. The oxygen supply subsystem is connected with the temperature reduction and dehumidification subsystem by virtue of an oxygen pipeline, the carbon dioxide / carbon monoxide absorption subsystem is connected with the temperature reduction and dehumidification subsystem by virtue of a ventilation pipeline, and the temperature reduction and dehumidification subsystem utilizes kinetic energy of oxygen and kinetic energy of the purified air to enhance heat exchange. The system in the invention makes the best of reactive power of the oxygen supply subsystem and the carbon dioxide / carbon monoxide absorption subsystem to realize forced heat exchange of the temperature reduction and dehumidification subsystem, so that the system can normally operate without electric power supply; and the temperature reduction and dehumidification subsystem adopts a refrigerant storage bottle to substitute a compressor and a condenser, thus ensuring the system to operate normally under the condition of no electric power supply.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Catalyst for carbon monoxide conversion and method of carbon monoxide modification with the same

InactiveUS7776785B2High activityIncreased durabilityHydrogenFinal product manufactureFuel cellsHydrogen

The invention provides a catalyst for carbon monoxide conversion, comprising from 10 to 90% by mass of a copper oxide ingredient, from 5 to 50% by mass of a zinc oxide ingredient and from 10 to 50% by mass of an aluminum oxide ingredient, and having a specific surface area of from 100 to 300 m2 / g, a carbon monoxide adsorption of from 20 to 80 μmol / g, and a copper oxide crystallite diameter of at most 200 angstroms, as a catalyst suitable for carbon monoxide conversion for fully reducing carbon monoxide in the hydrogen gas obtained through reforming of a starting hydrocarbon material, for the purpose of enabling stable long-term operation of a fuel cell which uses hydrogen gas as a fuel and which is frequently and repeatedly started and stopped.

Owner:IDEMITSU KOSAN CO LTD

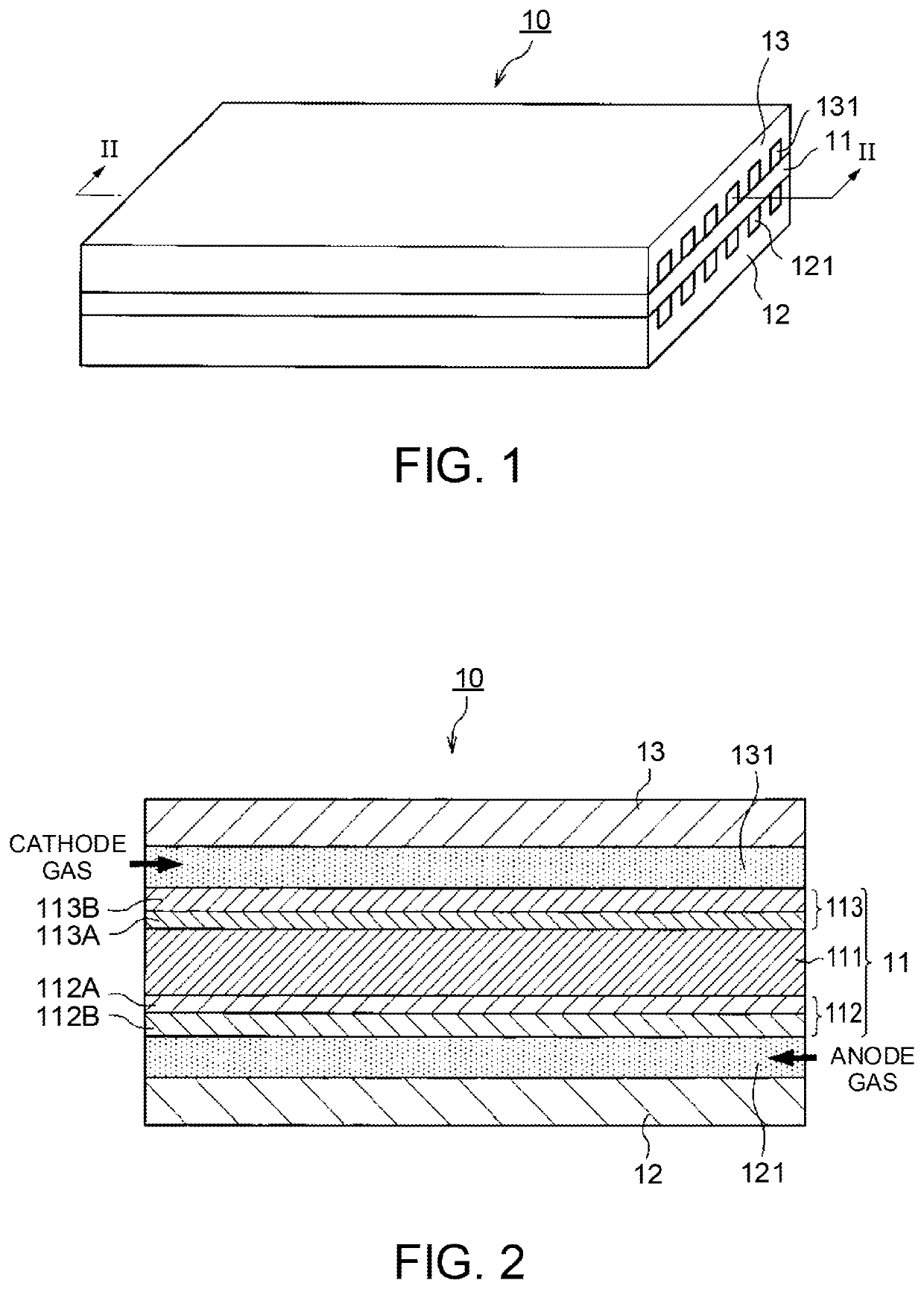

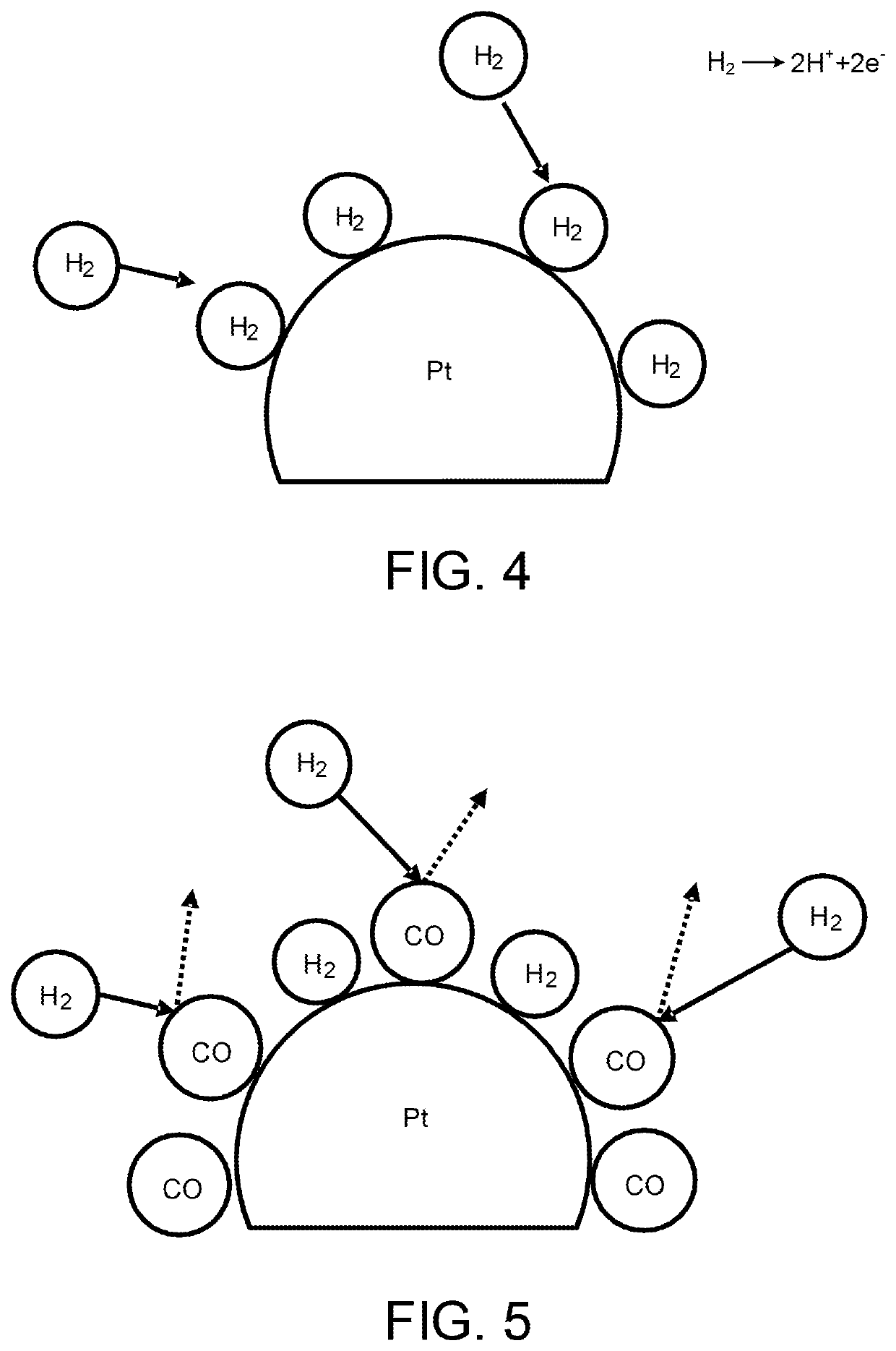

Catalyst deterioration recovery device and catalyst deterioration recovery method

ActiveUS20200185746A1Inhibit deteriorationPerformance deteriorationSolid electrolyte fuel cellsPtru catalystFuel cells

A catalyst deterioration recovery device in a fuel cell system that includes a fuel cell including a membrane electrode assembly configured to include an electrolyte membrane and anode and cathode catalysts between which the electrolyte membrane is sandwiched from both sides and anode and cathode separators respectively including an anode gas flow channel and a cathode gas flow channel, the membrane electrode assembly being sandwiched between the anode and cathode separators. The catalyst deterioration recovery device recovers performance decreased by adsorption of carbon monoxide to the anode catalyst. The catalyst deterioration recovery device includes a recovery control unit configured to supply at least a part of oxygen to be supplied to the cathode gas flow channel to the anode catalyst via the electrolyte membrane.

Owner:NISSAN MOTOR CO LTD

carbon monoxide adsorbent

ActiveCN103418337BImprove adsorption capacityReasonable compositionOther chemical processesMolecular sieveAluminium hydroxide

A carbon monoxide adsorbent comprises the following raw materials, by weight: 38 to 42% of cuprous chloride, 18 to 23% of 13X molecular sieves, 8 to 10% of aluminium hydroxide, and 28 to 35% of purified attapulgite powder. The adsorbent is produced by the following steps: a. the 13X molecular sieves are baked in a 200 DEG C oven for 120 to 150 minutes; b. the four raw materials are mixed into a mixed material, which is put into a kneader, purified water, the weight of which is 10% of that of the mixed material, is added into the kneader for kneading for 20 to 25 minutes, and kneaded material is obtained; c. the kneaded material is then processed by an strip extruder into strip-shaped objects with sizes between phi 3 mm * 8 mm and phi 3 mm * 15 mm; and d. the strip-shaped objects are put into the oven, baked at a temperature between 300 and 320 DEG C for 180 to 200 minutes, then taken out, and made into the carbon monoxide adsorbent after natural cooling. The carbon monoxide adsorbent is scientific in combination. Especially by adding 200 mesh purified attapulgite powder which undergoes crushing, purification, ultrafine processing and activation processing, the carbon monoxide adsorbent is improved in adsorption capability and substantially lowered in cost. The price of the carbon monoxide adsorbent is two thirds of those of similar products.

Owner:程会 +1

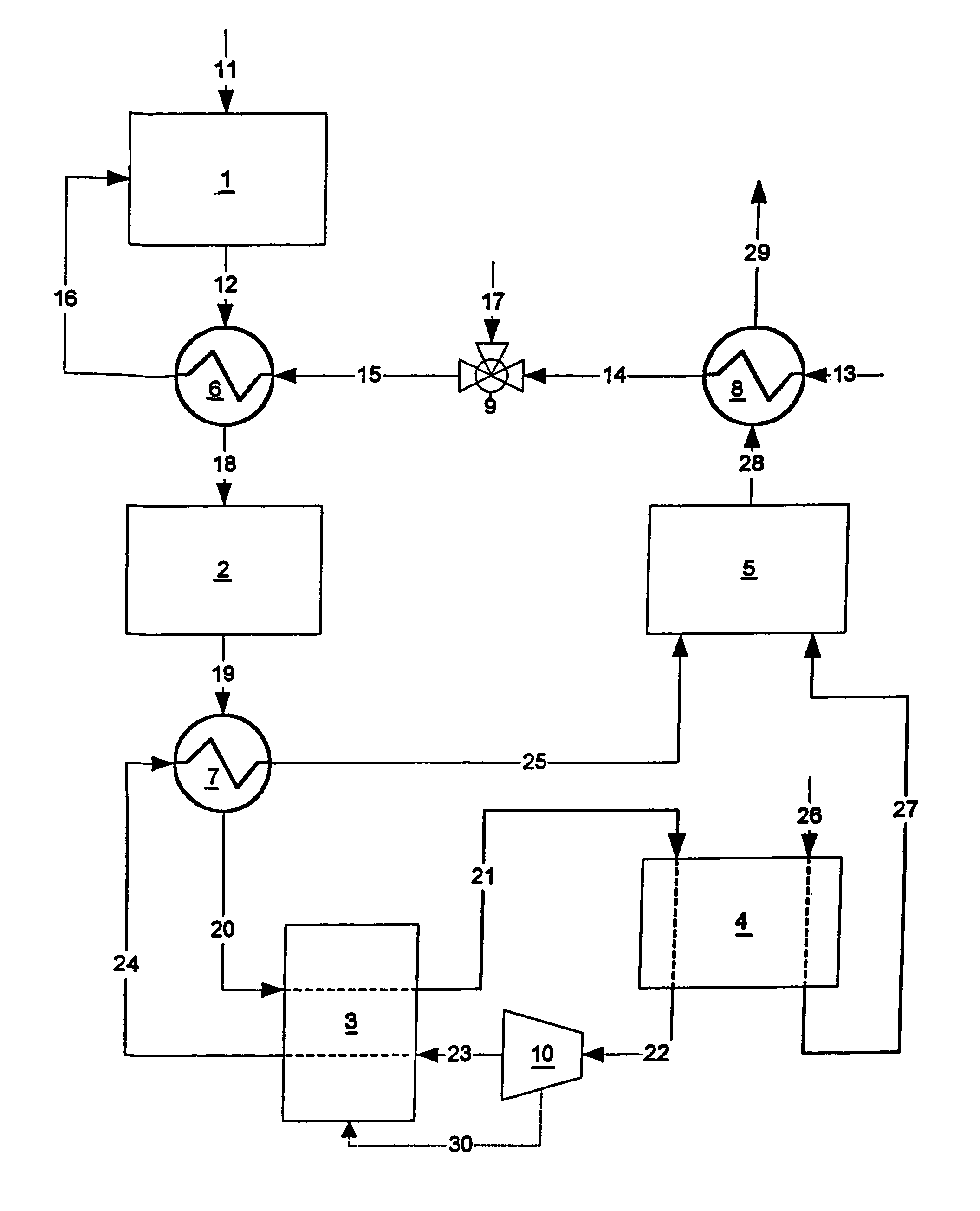

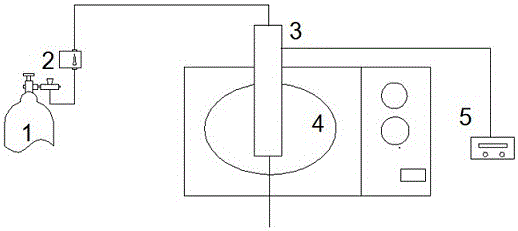

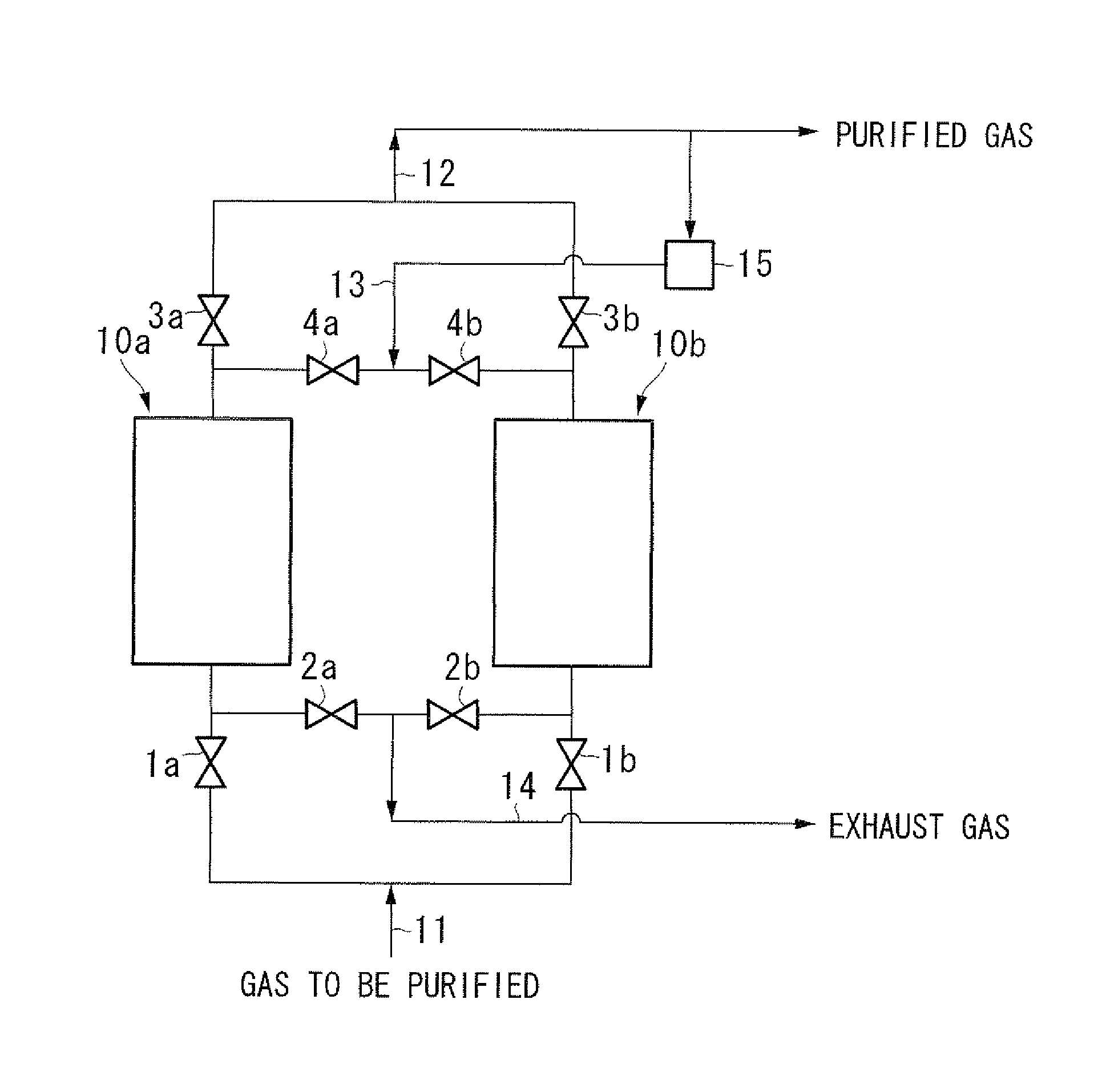

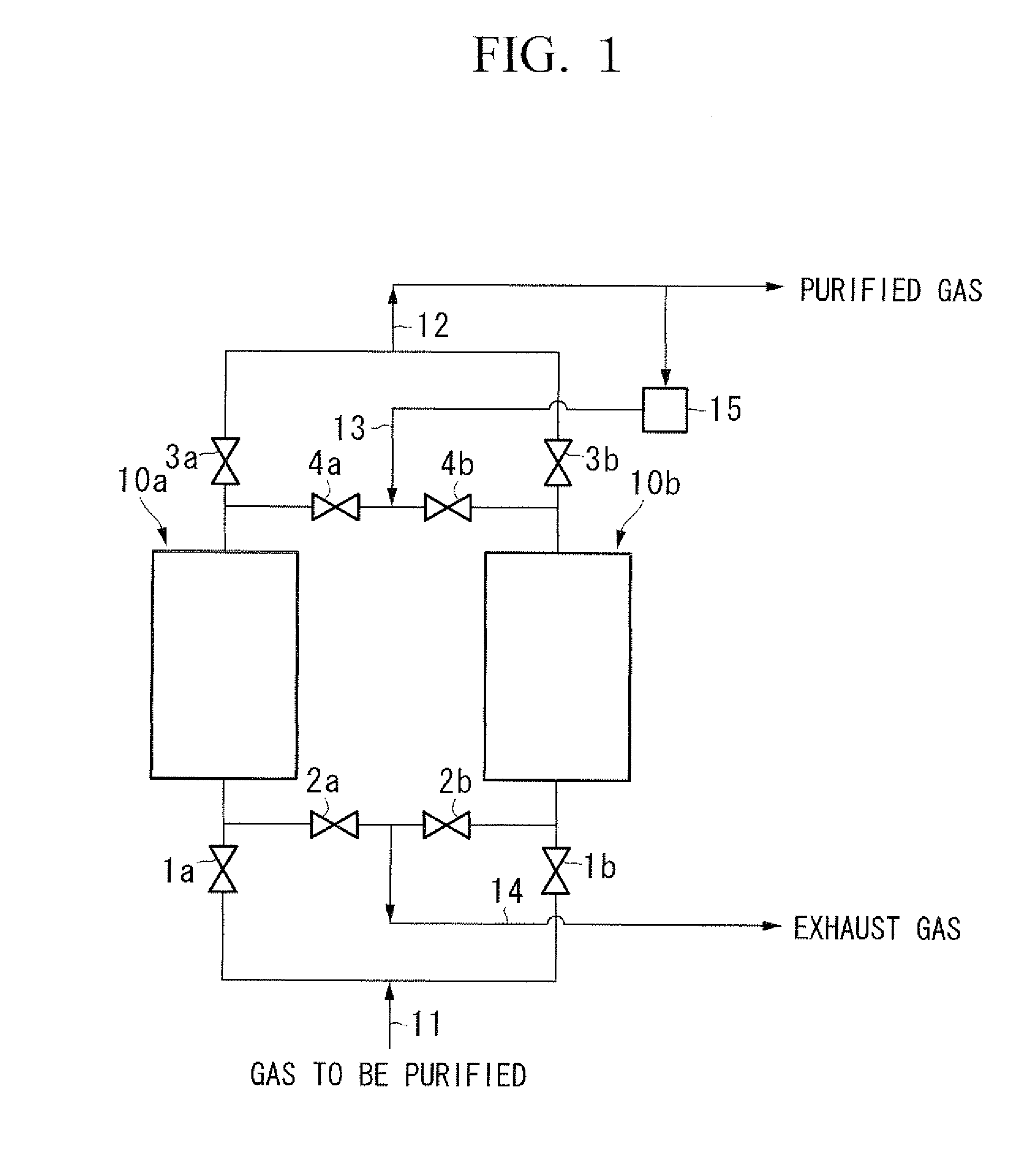

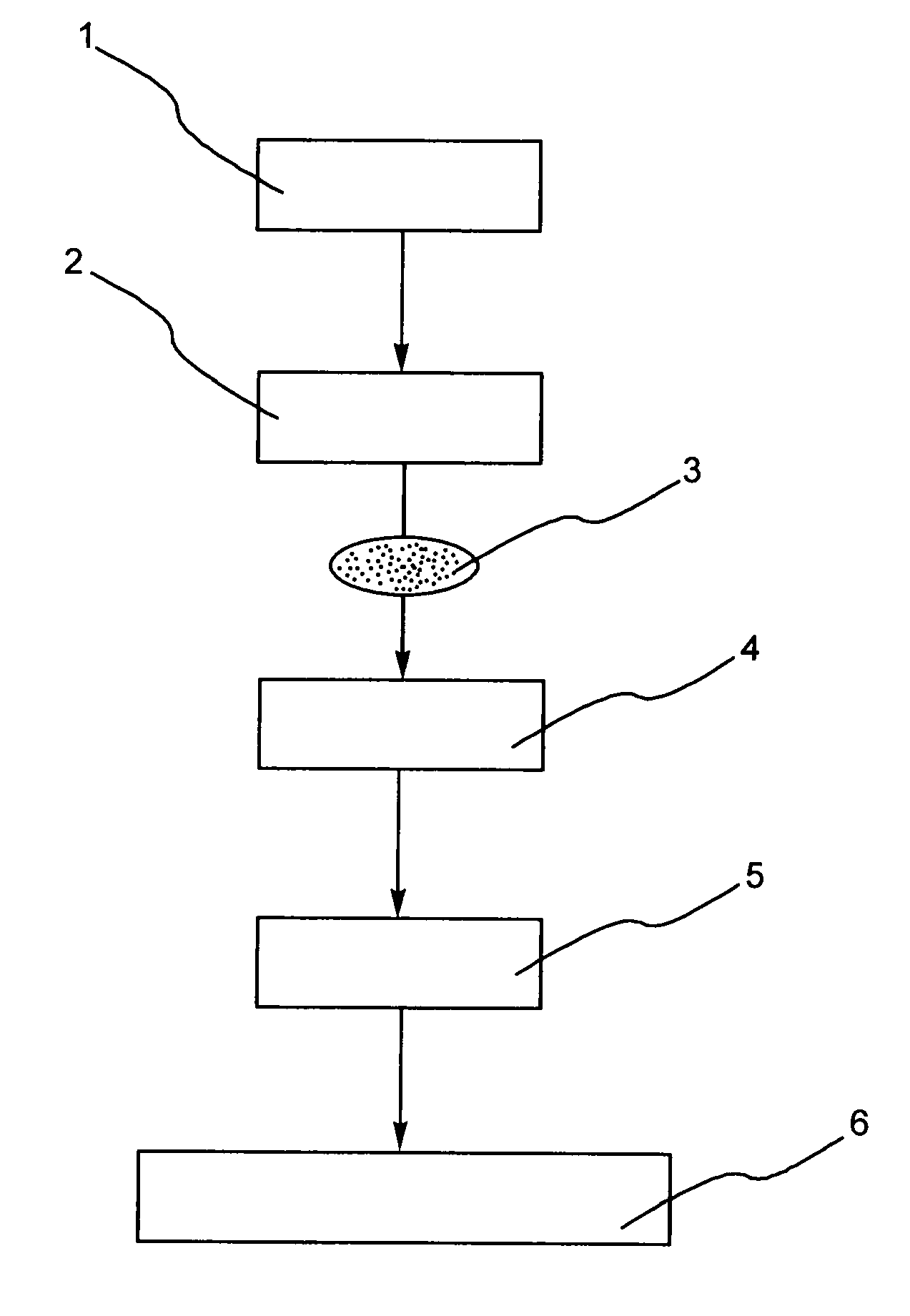

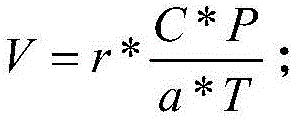

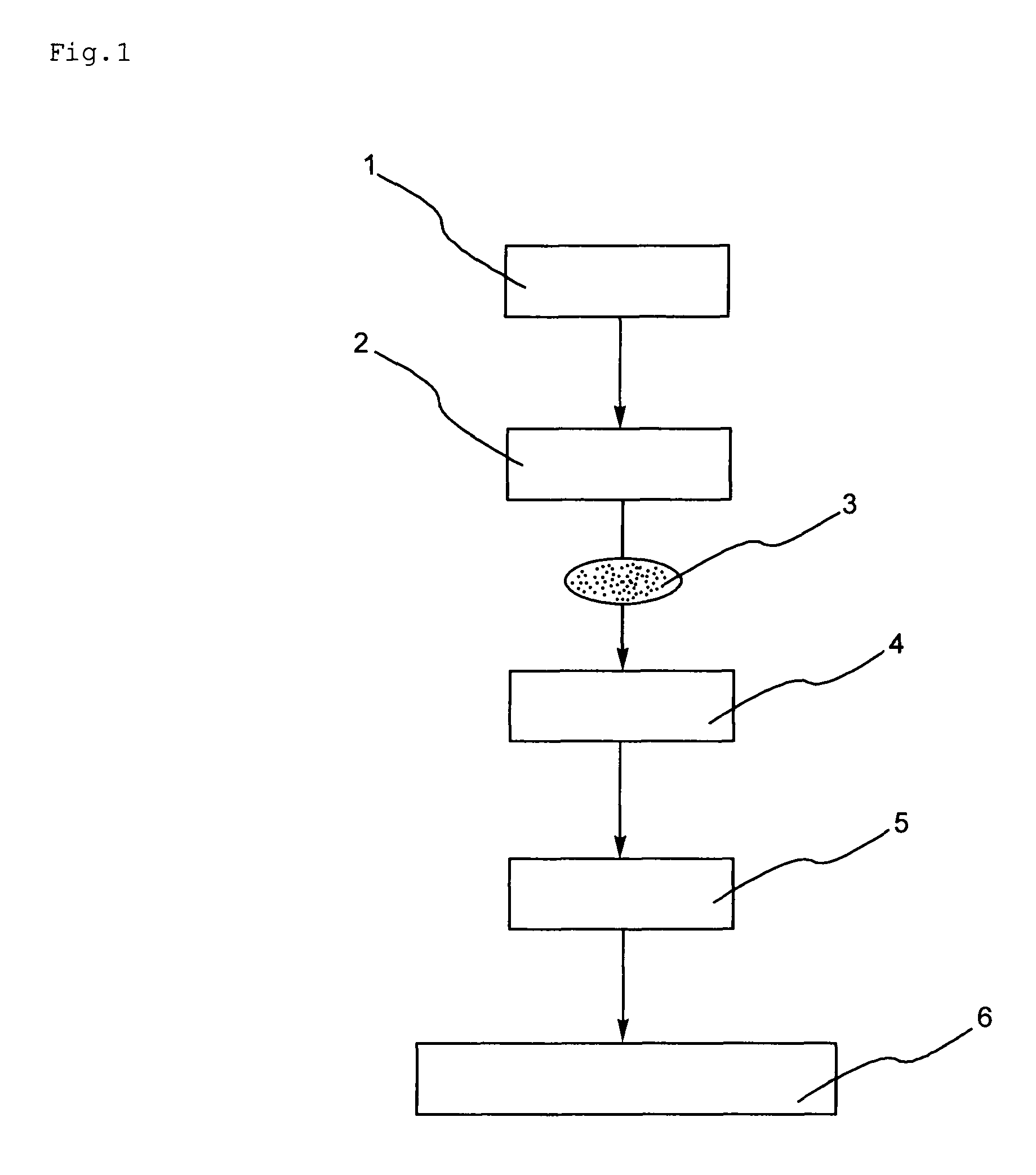

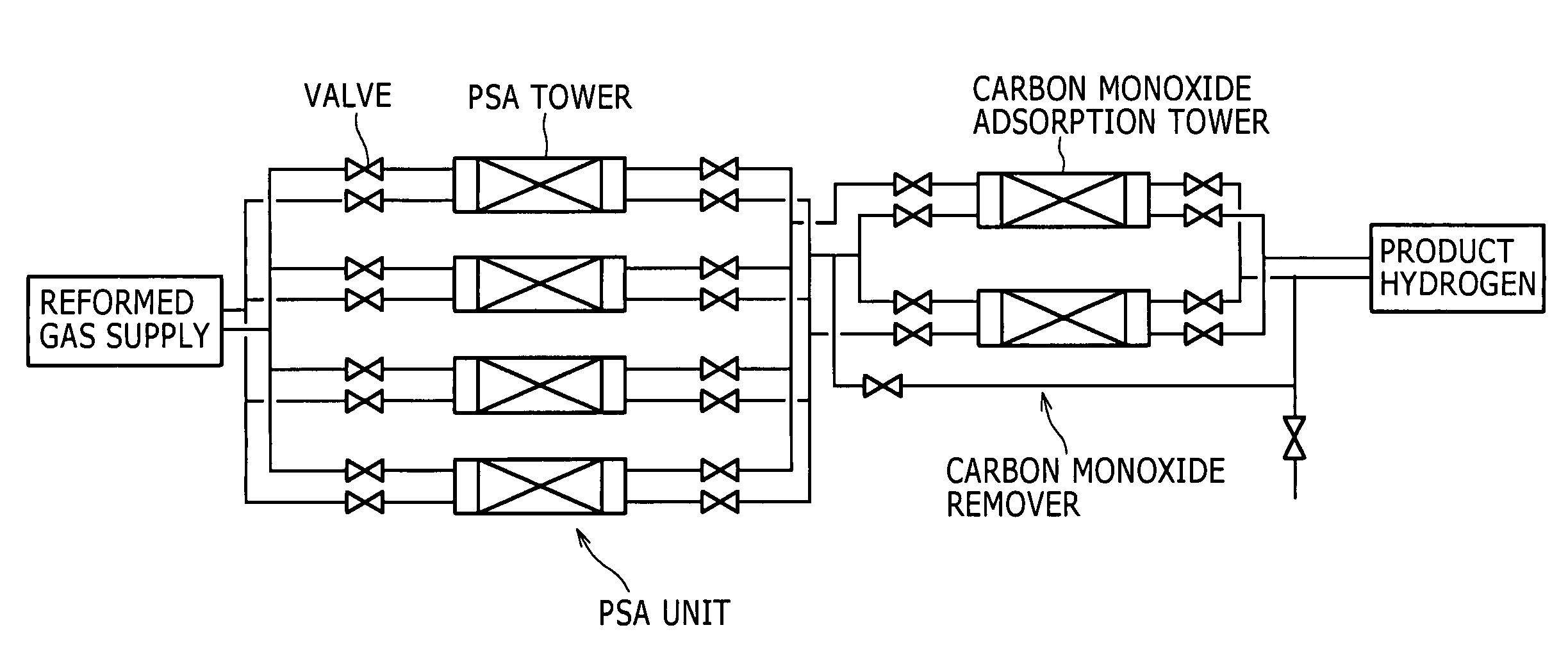

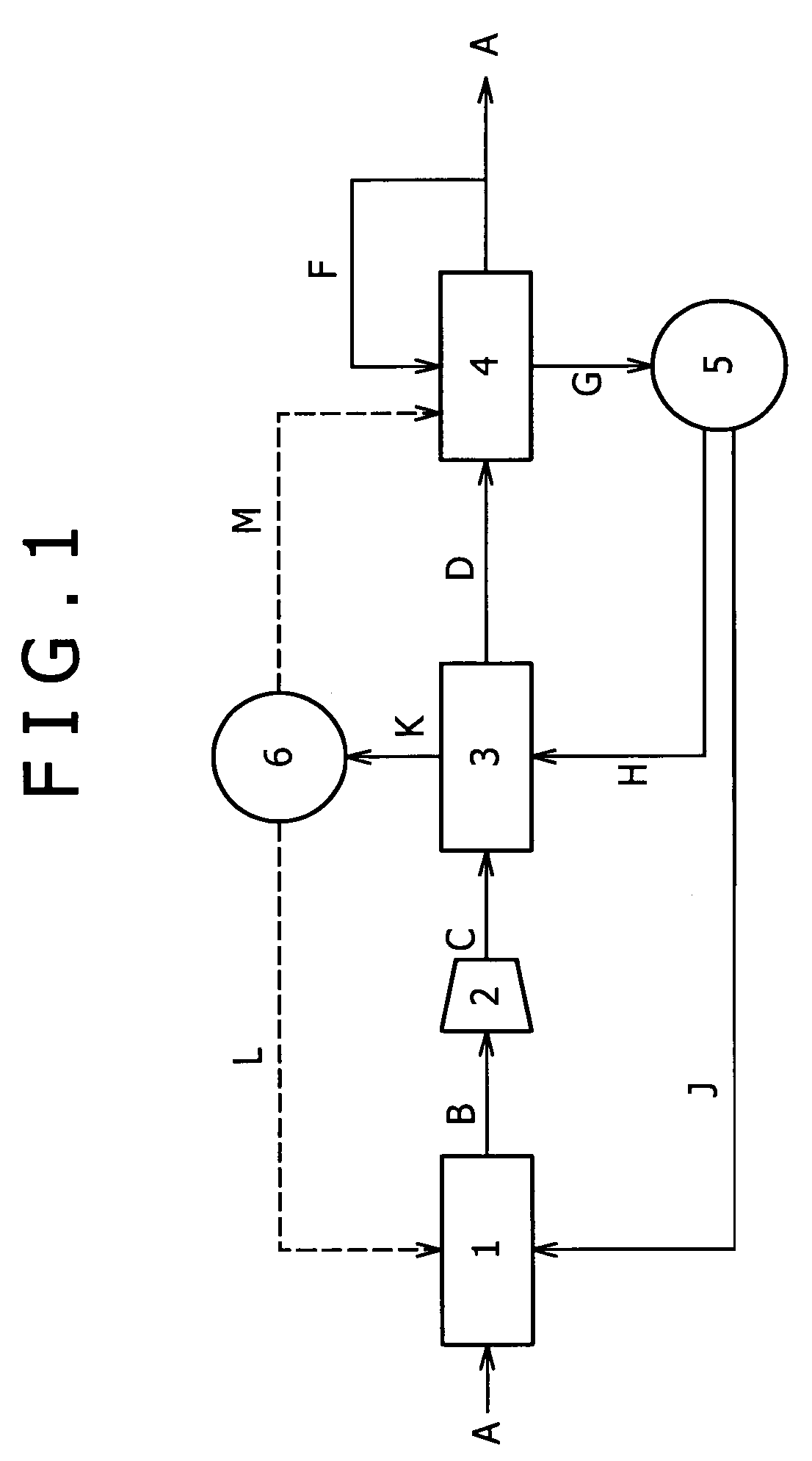

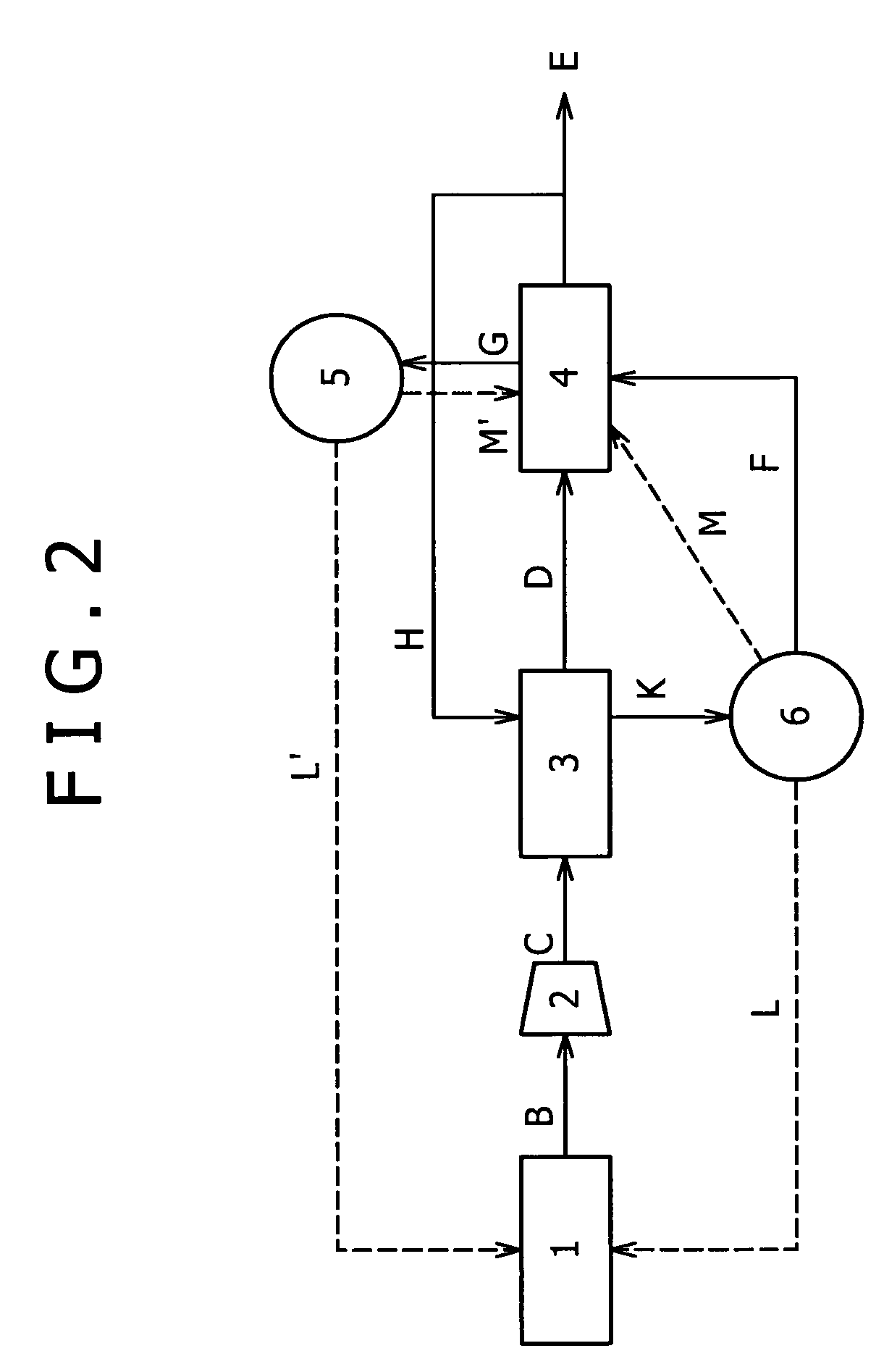

Method of producing high-purity hydrogen

InactiveUS8372375B2Maintaining abilityLowered adsorption abilityHydrogen separation using solid contactIsotope separationHydrogenSorbent

For recovering hydrogen with a high recovery from a reformed gas and contributing to downsizing and cost reduction of facilities, a high-purity hydrogen E is obtained by reforming a reformable raw material A through a reforming unit 1 to yield a hydrogen-rich reformed gas B, compressing the hydrogen-rich reformed gas B with a compressor 2, allowing the compressed gas to pass through a PSA unit 3 to remove unnecessary gases other than carbon monoxide by adsorption, and allowing the resulting gas to pass through a carbon monoxide remover 4 packed with a carbon monoxide adsorbent supporting a copper halide to remove carbon monoxide by adsorption.

Owner:KOBE STEEL LTD

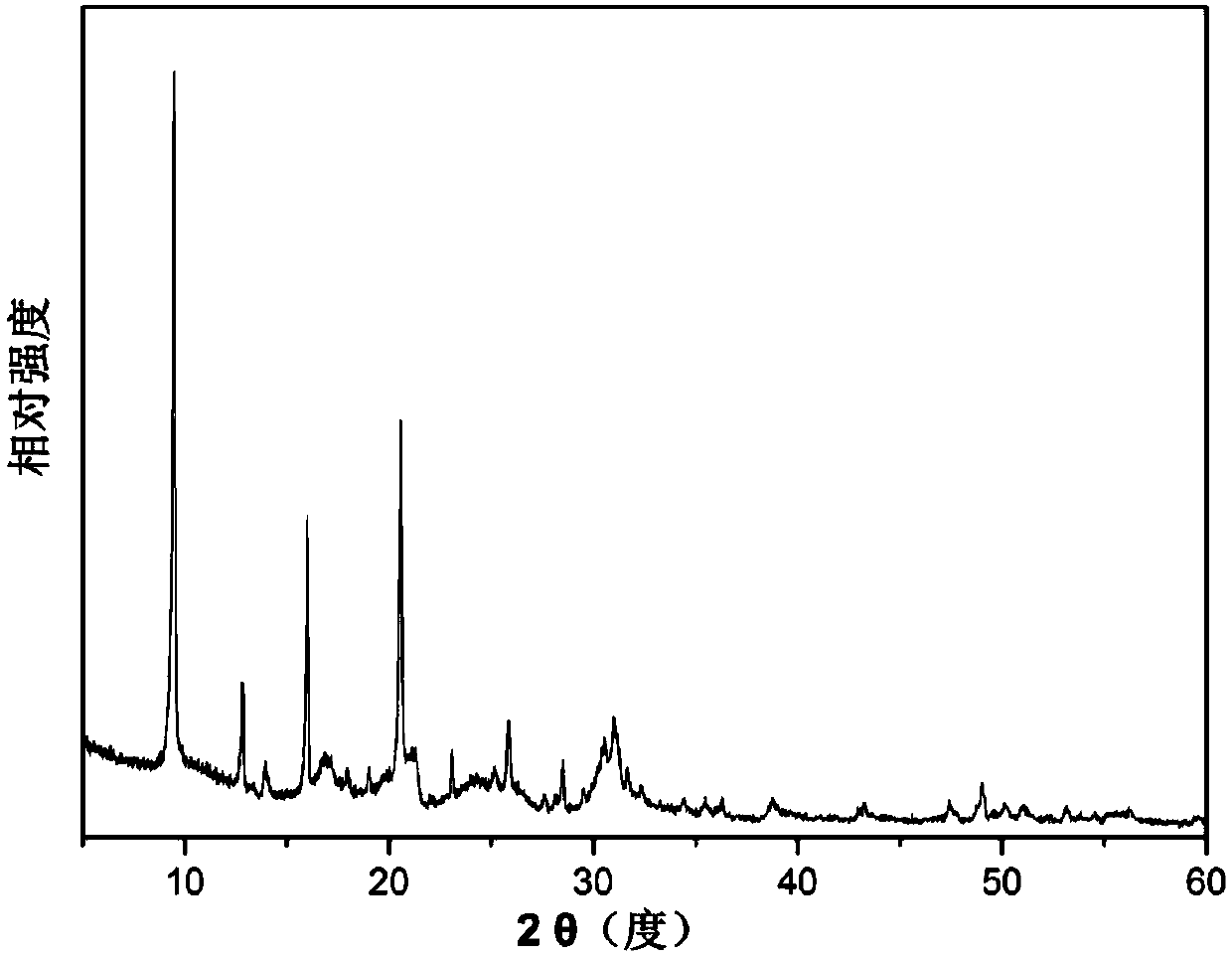

Carbon monoxide adsorbent, preparation method and applications thereof

InactiveCN110652960AImprove adsorption capacityEasy to prepareGas treatmentOther chemical processesMolecular sievePhosphoric acid

The invention discloses a carbon monoxide adsorbent, a preparation method and applications thereof, wherein the carbon monoxide adsorbent comprises a carrier and a cuprous compound, and the carrier isa silicoaluminophosphate molecular sieve. According to the invention, the adsorbent is simple in preparation process and high in adsorption capacity, and has good industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

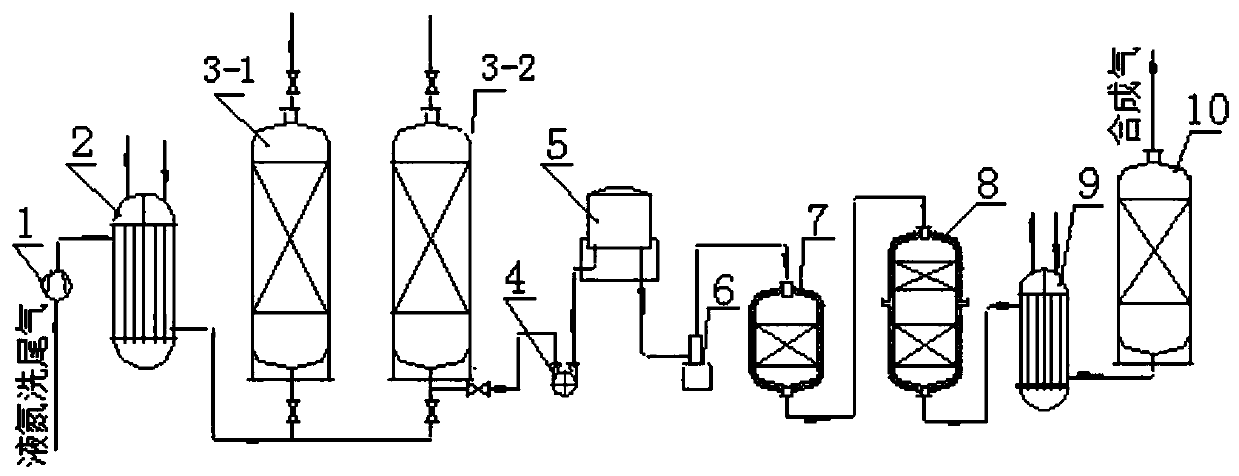

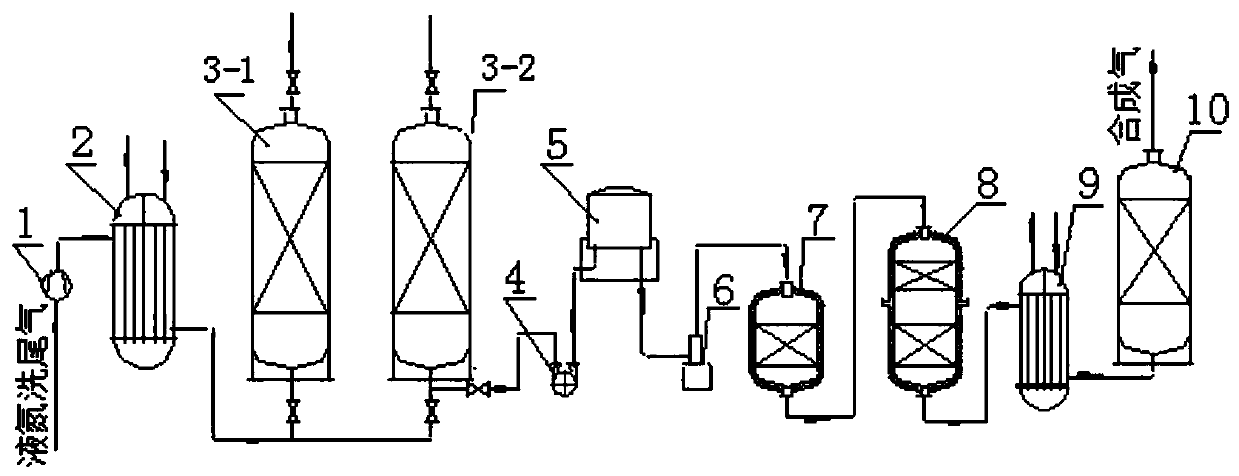

Method and device for recycling liquid nitrogen washing exhaust gas

The invention provides a method and a device for recycling a liquid nitrogen washing exhaust gas and belongs to the field of energy utilization and environmental protection. The method comprises the following steps: boosting and water-cooling the liquid nitrogen washing exhaust gas in turn, thereby acquiring a pretreated liquid nitrogen washing exhaust gas; performing carbon monoxide absorption onthe pretreated liquid nitrogen washing exhaust gas, thereby acquiring a carbon monoxide gas; compressing the carbon monoxide gas and then mixing with a first water vapor and performing high-temperature conversion, thereby acquiring a high-temperature conversion gas, wherein a high-temperature conversion catalyst B118 is applied to the high-temperature conversion; mixing the high-temperature conversion gas with a second water vapor and performing medium-low temperature conversion, thereby acquiring a medium-low temperature conversion gas, wherein a medium temperature catalyst B116 and a low-temperature catalyst B205 are applied to the medium-low temperature conversion; cooling and decarburizing the medium-low temperature conversion gas in turn, thereby acquiring a synthesis gas. Accordingto the method provided by the invention, the recycling of the liquid nitrogen washing exhaust gas can be realized and the acquired different synthesis gases can be used for industrial production.

Owner:YUNNAN TIANAN CHEM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com