Preparation method of carbon monoxide absorbent

A carbon monoxide and adsorbent technology, applied in the field of flue gas purification, can solve the problems of poor desorption performance and poor absorption effect, and achieve the effects of good industrial application prospects, low price and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

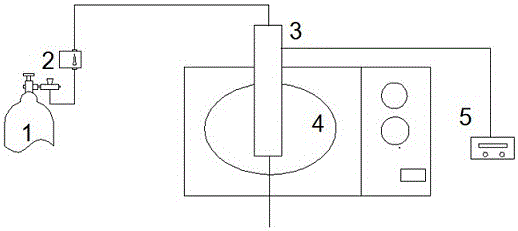

Image

Examples

Embodiment 1

[0023] The preparation method of the carbon monoxide adsorbent described in this embodiment specifically comprises the following steps:

[0024] (1) Clean the NaY-type molecular sieve, then put it into a muffle furnace and calcinate at 300°C for 3 hours, grind it into powder and pass it through a 60-mesh sieve;

[0025] (2) Immerse the NaY-type molecular sieve powder obtained in step (1) in 1mol / L CuCl at a solid-to-liquid ratio of 1:5 2 In the solution, then add cerium nitrate to obtain mixed impregnation solution, the addition of cerium nitrate is 5% of molecular sieve quality;

[0026] (3) Put the molecular sieve solution into the reactor, and feed N at a rate of 300ml / min 2 As a shielding gas, the irradiation reaction was carried out with 450W power for 5min.

[0027] (4) Suction filter the molecular sieve obtained in step (3), then dry the filter cake in the reactor with 400W power for 10min, then put it into the tube furnace and pass it with N 2 As a protective gas, i...

Embodiment 2

[0031] The preparation method of the carbon monoxide adsorbent described in this embodiment specifically comprises the following steps:

[0032] (1) Clean the NaY molecular sieve, then put it into a muffle furnace and calcinate at 400°C for 3.5 hours, grind it into powder and pass it through an 80-mesh sieve;

[0033] (2) Immerse the NaY molecular sieve powder obtained in step (1) in 1.2mol / L CuCl at a solid-to-liquid ratio of 1:8 2 In the solution, then add cerium nitrate to obtain mixed impregnation solution, the addition of cerium nitrate is 3% of molecular sieve quality;

[0034] (3) Put the molecular sieve solution into the reactor and feed N at a rate of 500ml / min 2 As a shielding gas, the irradiation reaction was carried out with 550W power for 5.5min.

[0035] (4) Suction filter the molecular sieve obtained in step (3), then dry the filter cake in the reactor with 300W power for 15min, then put it into the tube furnace and pass it with N 2 As a protective gas, it wa...

Embodiment 3

[0039] The preparation method of the carbon monoxide adsorbent described in this embodiment specifically comprises the following steps:

[0040] (1) Clean the NaY-type molecular sieve, then put it into a muffle furnace for calcination at 350°C for 3 hours, grind it into powder and pass it through a 120-mesh sieve;

[0041] (2) Immerse the NaY-type molecular sieve powder obtained in step (1) in 1.4mol / L CuCl at a solid-to-liquid ratio of 1:10 2 In the solution, then add cerium nitrate to obtain mixed impregnation solution, the addition of cerium nitrate is 3.5% of molecular sieve quality;

[0042] (3) Put the molecular sieve solution into the reactor, and feed N at a rate of 600ml / min 2 As a shielding gas, the irradiation reaction was carried out with 650W power for 6min.

[0043] (4) Suction filter the molecular sieve obtained in step (3), then dry the filter cake in the reactor with 450W power for 10min, then put it into the tube furnace and pass it with N 2 As a protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com